Additive manufacturing is seen by many as one of the main driving forces behind the digital manufacturing revolution. Digital manufacturing integrates advanced technology like CAD (Computer-Aided Design), AI (Artificial Intelligence), and IoT (Internet of Things) to enhance performance, efficiency, and precision.

According to analysts, digital manufacturing is on the rise. The sector will see a value of $0.44T by the end of this year. This growth will continue at an estimated CAGR of 19.40% for the next five years, hitting a value of $1.07T by 2030. Much of this growth will come from integrating 3D printers and other advanced tech into the manufacturing process.

What is Additive Manufacturing?

Additive manufacturing is a term that refers to the process of creating an object by building up layer upon layer. This process is the opposite of subtractive manufacturing, which refers to chipping away at a larger object to create a product.

The additive manufacturing process can involve any number of materials. Today’s 3D printers can utilize polymers, metals, ceramics, concrete, foams, gels, and even biomaterials to create products. Additionally, different styles of printers use different strategies ranging from lasers to special hardening powders and ovens. This flexibility reflects the innovation the sector continues to embrace.

How Additive Manufacturing Works

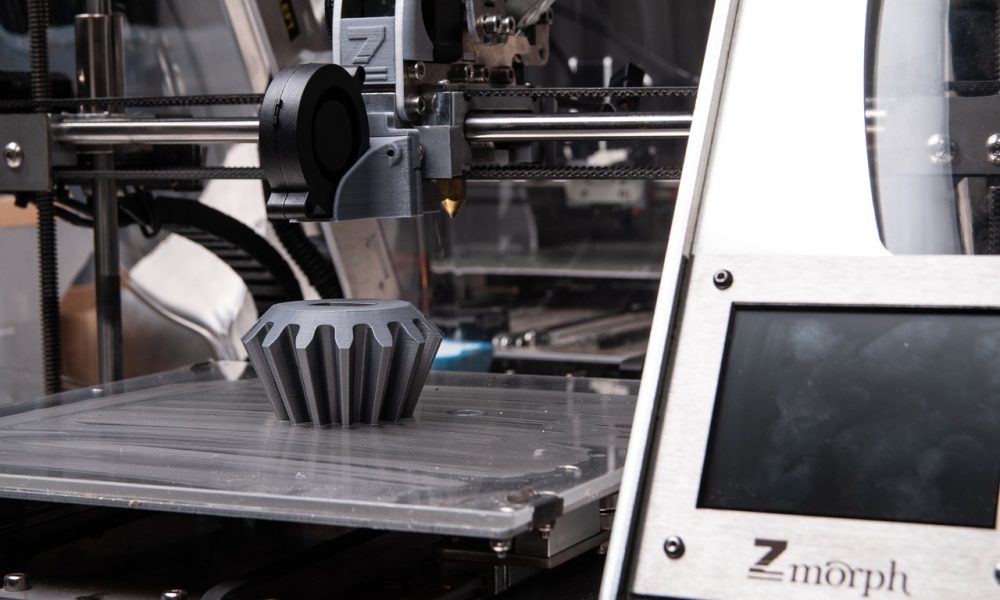

The additive manufacturing process begins with a design. The first step is to utilize CAD software or a 3D scanner to provide digital input for the layer framework protocol. The layered framework protocol translates the design into slivers that the 3D printer can understand.

In the most common method, a nozzle adds successive layers of the material to build up the item matching the design. From there, the material will harden due to chemical, heat, or other factors depending on the 3D printing process.

Source – Autodesk CAD Design

Many Ways to 3D Print

There are several ways to 3D print objects and depending on the size and requirements, a specialty 3D printer is the only option. There are purpose-built printers that can create microscopic pieces or electrical components. There are even 3D printers that build entire neighborhoods.

This range of printing processes also means that 3D printing can take anywhere from hours to days to complete, depending on the scope and intricacies of the print. Additionally, there are now systems that print using multiple materials. These additive manufacturing tools can take longer as there is a curing time between the use of each material in most instances.

Holographs

When you think of additive manufacturing you must understand that there are many ways to build up a product using layers. One group of advantageous engineers even created a method of using holographs to print through the skin. The same technology could be used to repair parts without removing them or even to print organs in place.

Benefits of Additive Manufacturing

The benefits of additive manufacturing continue to stack up. For one, 3D printing opens the door for more intricate and precise parts. Providing engineers with the capability to create complex geometries, using multiple materials, and even moving parts enables a new level of creativity and innovation.

Parts manufactured using precise 3D printing methods provide higher performance and precision compared to traditional methods. For small-scale industrial use, 3D printing improves product performance and allows engineers to make small tweaks to their designs without having to restart the industrial manufacturing process.

Cost Savings

One of the main reasons why additive manufacturing has grown so popular is that it reduces the process across the board. In a traditional manufacturing plant, items get shipped in, worked on, and then shipped to their next destination until the final product emerges. In a 3D printing process, everything is created on-site. As such, there are serious reductions in setup costs when discussing producing small lot sizes.

The ability to send your designs straight from your computer to a printer means that companies and designers can prototype and test their theories faster and without the need to utilize a third party. All of these factors have made additive manufacturing an attractive option.

Flexibility

Additive manufacturing brings unmatched flexibility to the market. Designers can 3D print using a huge selection of natural and manmade materials. They can even decide to make printers that combine multiple materials. These complex designs can be functional or stand-alone. Additionally, they can include electrical components, adding to the overall versatility of this process.

Additive manufacturer designs have a major advantage in that they can leverage different material properties to create unique products. Engineers can create new lightweight materials and prints that shave weight off of traditional designs to better improve aerodynamics, battery life, or comfort.

Sustainability

Sustainability concerns are a major issue when discussing current manufacturing processes. The global community agrees that there is a need to reduce pollution and the environmental impact of the industrial sector. Additive manufacturing can help achieve this goal because it does away with the majority of waste material.

The process of layering to create an object already reduces much of the waste versus subtractive manufacturing where an item gets carved out and the excess material discarded. The best 3D printers produce very little waste in the form of pieces that need to be smoothed or removed following the print. Additionally, they can print using recycled materials.

Another environmental factor that gets overlooked is travel costs. Science 3D printing usually occurs in a single location, there’s no need to ship parts to their next destination. This strategy can save companies on gas and reduce pollution caused by the global logistics sector.

Functionally-Graded Materials

One of the biggest benefits of 3D printing is the ability to utilize different materials on prints. For example, you may want to print an item that has conductivity on the inside but is shielded around the core. In a traditional manufacturing setting, this item would require multiple steps and processing plants to achieve.

Additive manufacturing enables engineers to print a metallic core that demonstrates conductivity. They can print the core. Then, a ceramic or another abrasion-resistant material can be printed to shield it from interference. This process can be done by the same machine during the printing execution stage, eliminating much of the original manufacturing costs and technical requirements.

Additive Manufacturing History and Key Moments

The concept of 3D printing has been around for a long time. It originats back to as early as 1977 when Wyn Kelly Swainson first filed for a patent on a laser plastic coating system. This system simply heated up plastic in a pool, which coated a device inside. By the 1980s, the 3D manufacturing market had begun to take flight.

It was at this time, the technology became a premier prototyping option. Rapid prototyping enables engineers to quickly test and correct their creations long before computer simulations existed that could work out the kinks. In most instances, 3D printers would be used to create scale models.

In 1986, Chuck Hull introduced the UV light method to create crosslink layers. This process relied on a newly invented photopolymer material that would heat up and harden when lasers were applied to it. This development led to the use of a 3D printers to make molds for traditional manufacturing plants.

Organs

In 1999, 3D printers entered the healthcare arena after a team of Wake Forest engineers successfully 3D printed a bladder. The bladder was printed using a special additive manufacturing process that cultured cells. Notably, this event marked the first time anyone 3D printed an organ. Impressively, It spawned a new sector in the 3D printing industry which still thrives today.

Functional Products

The 2000s marked a change in additive manufacturing processes. It was at this time that 3D printers became more accessible to the public. As such, you started to see them in use by regular people to create parts, art, and more. In 2005, a French artist named Patrick Jouin made international headlines after revealing 3D prints of a functional chair.

Some additional breakthroughs occurred in the decade that drove adoption. Specifically, the University of Michigan successfully 3D printed a splint that went on to save a child’s life. Additionally, Boeing began 3D printing components for its Dreamliner planes, These were the first FAA-approved 3D printed titanium parts to hit the market, marking another milestone for the technology.

Future of Additive Manufacturing

The future of additive manufacturing looks like something straight out of a sci-fi movie. Imagine going to the hospital and getting your liver printed inside your body through your skin. While this may seem like wizardry, it’s not that far away. Researchers have already successfully used holographic sound waves to print devices through a thin skin-like membrane. In the future, this same tech could make surgeries non-invasive, or enable repairs without disassembly first.

Additive Manufacturing Industry Applications

As the Digital Manufacturing revolution continues at a breakneck pace, they’re several applications for this technology. The ability of additive manufacturing processes to increase the performance and precision of end-use parts, reduce weight, and lower overall costs, makes it a smart option for small lot manufacturing and customization. Here are the key industrial applications of this tech.

Aerospace

The aerospace industry relies on 3D printing to create lightweight composite pieces that provide stability and durability while fitting into tight form factors. Already Boeing and General Electric rely on additive manufactured parts on multiple aircraft.

Notably, Boeing (BA +0.68%) was the first aircraft manufacturer to secure FAA approval for a titanium 3D printing method to create parts. Since then, they have begun using additive manufacturing to create a variety of parts using many different materials. This manufacturing process could one day be used to create vehicles or components for Space travel.

The aerospace community could rely on 3D manufacturing for the inflight processes as well. Future space travelers won’t carry tools with them. Instead, they can have the tools they need, printed in minutes. Even more impressive is the thought of a future space traveler printing up an organ to save a life.

Healthcare

Additive manufacturing has made serious inroads into the healthcare industry where its many use cases have helped it to build up support for the tech. There are 3D printers that create customized products, like prosthetics or implants. Their flexibility and availability make these devices the best, and sometimes, the only solution for those in need. In the future, you may find 3D printers in ambulances.

3D Printed Prosthetic

Notably, hearing aids are a mostly 3D-printed product that continues to leverage advancements to streamline the creation process. Today’s advanced hearing aids are modeled directly from the patient’s ear. The ability to take customized scans and print small batches of products makes additive manufacturing the best option in this scenario.

Your local pharmacy may be the next location in your neighborhood to get a 3D printer. The use of 3D printers to create drugs has been growing internationally. These systems eliminate human error and can provide faster response time. Impressively, there has been a lot of work put into the quality control of these systems as a small miss print could result in injury or even death when discussing medications.

Automotive

The rise of EVs is another factor that has pushed automotive manufacturers towards 3D-printed components. Every pound matters when discussing EVs. As such, manufacturers have turned towards plastic, composites, and light metals as ways to reduce weight and extend range. In the future, you will see more car components 3D printed using an all-inclusive design that eliminates the need for multiple stops along the creation process.

Construction

Imagine watching your house get 3D printed in front of your eyes. Impressively, this tech is already in use and has shown serious promise. Notably, entire neighborhoods have been printed using these massive additive manufacturing machines that come in several different designs.

Some utilize concrete, while others rely on compacted dirt or other mixtures. Impressively, 3D-printed houses can integrate unique architecture that helps reduce heating and cooling costs, furthering sustainability.

Additive Manufacturing Investment Trends

You can see the formation of several investment trends in the 3D printing sector. The four common positions on the value chain include materials, core, software, and applications. Materials regard companies that create composites or other key materials that are requirements of the 3D printing process.

The core segment includes developers, 3D printing manufacturers, and researchers. Whereas, Software investors will seek out new protocols that help to drive efficiently or introduce new features. AI is a prime example of a software-based additive manufacturing strategy that has seen success. AI systems can make 3D printing easier for the average person and enable anyone to use test prompts to design and develop 3D prints with ease.

Several companies are leading in innovation across the 3D printing market. Stratasys (SSYS +2.16%), Desktop Metal (DM -8.63%), and Velo3D (VLD -5.19%) all provide valuable service to the market. As such, they are recognized as leaders in the industry. Their research has helped to drive efficiency and expand the market.

Consolidation is on the Horizon

According to ARK’s Big Ideas 2025 study, the additive manufacturing sector experienced strong consolidation throughout 2024. This consolidation was led by Nano Dimensions’ acquisition of Markforged and then, Desktop Metal in short succession. The same data revealed that large conglomerates have decided to look internally to meet their future 3D printing needs.

Another trend that the study revealed was that the rise in drones has led to more demand for 3D-printed parts, printers, and materials. Drones have found a home in multiple industries ranging from logistics and entertainment, all the way to weapons of war. As such, the desire for lightweight yet durable components has made additive manufacturing the best option.

Moving forward, you will have more consolidation as countries seek to take the market lead. Already, newly elected President Trump has started to push for more domestic manufacturing. This push could lead to the creation of large advanced additive manufacturing facilities throughout the US in the coming years.

Looking forward, ARK is even more optimistic than many analysts, envisioning 3D-printing revenues growing “…~40% at an annual rate to $180 billion by 2030”.

Barriers to Additive Manufacturing Adoption

Several factors slowed additive manufacturing adoption. For one, there are material limitations that engineers need to understand. When you 3D print an object, there are going to be stress points created. If not calculated correctly, they can lead to catastrophic failure. As such, engineers need to consider the material, the process used to create the object, and how they all interact.

Costs

Another hurdle to adoption is the high price of industrial-grade 3D printers. These machines can cost well over $100k and require a lot of room to operate. Additionally, 3D printing is only a better option when a limited number of customized products are required. When you zoom out to massive production operations, traditional methods are still more cost-effective in the long run.

Post-Processing

Another drawback to 3D printing is that there are additional steps required following the print’s completion. These steps can include removing excess material, sanding rough edges, and other alterations. The post-processing step can add to the cost and time of each print.

Quality Check

One of the biggest drawbacks of additive manufacturing is that it’s very difficult to locate internal defects. When you print a multi-material and layered object, it’s very difficult to peer into the inside of the device to ensure the printing process is completed accurately. Engineers continue to introduce new methods to enhance quality control, especially when discussing 3D drug printers.

One method introduced by engineers uses a laser to monitor each nozzle output. If a nozzle is shown to have lowered output, it can be assumed that there is an error in the print. Further testing using X-rays or other technologies can reveal internal stress points, cracks, or loose material, all of which could lead to catastrophic failure under intense conditions when discussing products, or bodily harm when talking about medications.

Additive Manufacturing will Drive Further Tech Integration

When you look at the history of 3D printing, it’s easy to see that it’s already changed production. In the coming years, more digital manufacturing processes will emerge and leverage 3D printers to create complex components on the go. As such, it’s safe to assume by 2030 that you will see 3D printers popping up everywhere, from your local drug stores to large manufacturing plants.

Learn about other additive manufacturing developments here.