This month, a team of creative engineers introduced a method to reduce the manufacturing of cooling systems, while boosting sustainability across multiple industries. Their work delves into enhancing the manufacturing process of thermoelectric materials. Here’s what you need to know.

Thermoelectric Coolers (TECs) are at the Forefront of Cooling Tech

Thermoelectric coolers are some of the most popular ingot-based cooling systems. Ingot refers to the molded manufacturing process. They leverage conductive material properties to regulate temperatures. Specifically, these systems can convert temperature differences to electrical voltage or reverse the process to cool areas.

To accomplish this task, TECs utilize electric current to migrate heat from one area to another designated location. The process is proven effective and can be customized using different sizes. Additionally, it reduces moving parts, furthering reliability.

Problems with Today’s Thermoelectric Coolers (TECs)

TECs are good, but they still lack in many aspects. For one, the ingot-based manufacturing process is very expensive and produces a lot of excess material that gets discarded as waste. Additionally, the manufacturing process requires an exorbitant amount of power, adding to the overall costs.

Thermoelectric Materials Study

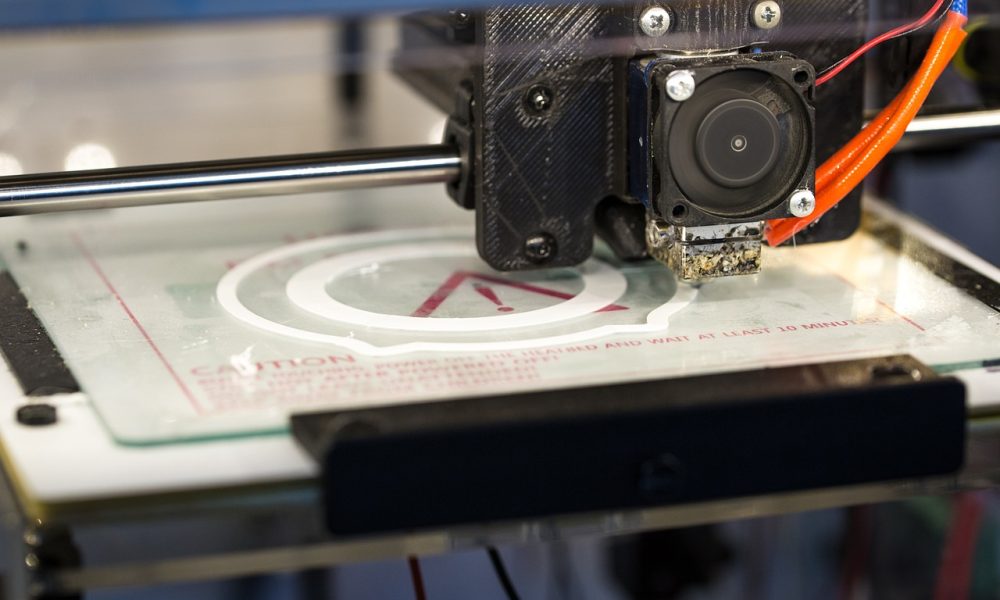

Recognizing these limitations, a team from the Institute of Science and Technology Austria (ISTA) introduced a novel 3D printing method to create thermoelectric materials. The study “Interfacial bonding enhances thermoelectric cooling in 3D-printed materials”1 published in the journal Science explains their process and findings in detail.

Source – WSS Felix Wey,

The team overcame previous attempts to 3D print optimized thermoelectric materials to create low-cost and effective cooling system alternatives. Their new method creates a highly customizable, stable, and durable end-product that could revolutionize several industries.

3D Printing Technique

At the core of their process is a specially built 3D printer. This unit features a customized extruder designed to use high-performance thermoelectric materials. These materials had impurities introduced purposely to create semiconductor capabilities.

New Inks

The engineers created a new ink substitute that combines bismuth antimony telluride and silver selenide. The extruder and ink were tested and fine-tuned to maximize the printed structures’ durability. Additionally, the team examined how to increase particle bonding in the prints.

Thermoelectric Materials Test Results

As the carrier solvent evaporates, the print begins to create strong atomic bonds between the added grains. This strong connection enhances the material thermal cooling effects without leaving any solvent residue.

The results are an atomically bonded material in whatever shape desired with high-performance thermoelectric characteristics. Specifically, the tests showed (zT) values of 1.42 for p-type bismuth antimony telluride and 1.3 for n-type silver selenide materials.

Operating at room temperature, the new material was able to produce a net cooling effect of 50 degrees in the ambient air. This level of cooling puts it on par with high-cost ingot-manufacturers alternatives that produce harmful byproducts and excess waste.

Thermoelectric Materials Study Benefits

There are several benefits that the 3D printed thermoelectric materials study brings to the market. For one, this is the first study to successfully produce thermoelectric coolers from printed materials. As such, it opens the door for innovations in the sector.

This transformative solution depends on the researcher’s understanding of how thermoelectric materials can be administered, as well as the transport properties of porous materials across various designs. This new perspective help can unlock breakthroughs in material science and thermoelectric cooling systems in the coming weeks and months.

Added Efficiency

The 3D printing method is far more effective than traditional ingot-based methods. Instead of stamping or molding a sheet of material, the 3D printer only utilizes the necessary materials needed to create the design.

Additionally, the unit can print intricate designs that would require multiple stamping processes to complete with traditional methods. This capability improves manufacturing for small batch processes with the ability to scale in the future.

Cut Costs

Testing shows that 3D-printed materials perform similarly to traditional options and cost much less. The reduced costs come from a variety of factors including the use of proprietary materials, eliminating waste, and improved processes.

Flexibility

The 3D-printed thermoelectric manufacturing process can be adapted to work with a massive selection of materials. This capability enables engineers to create new materials that are specifically designed for their purpose and are printed to the exact shape needed.

The ability to utilize customizable materials will lead to the creation of more efficient, high-performance, and more durable devices entering the market. Engineers can print intricate designs that could even include functioning electrical circuits, further reducing manufacturing steps and costs.

Thermoelectric Materials Applications

There are many applications that the thermoelectric materials study could be put towards. For one, it has been use in rapid heat management in electronics and mechanical devices. The ability of this material to operate at room temperature makes it ideal for most scenarios, including reducing the heat of wearables.

Power Generation

Another use case scenario for this technology is in power generation. These devices could help engineers develop next-generation high-temperature thermoelectric generators that can produce electrical voltage from the slightest temperature differences.

Better Computers

This new manufacturing process could improve the way computers are built. Imagine devices that utilized thermoelectric materials as their base to further reduce heat. This approach would enable units to be made more compact and with less weight.

Aerospace

The ability to create more compact devices will lead to more advanced aerospace ventures. The cost of carrying a single pound into space sits at $1200. This rate is far cheaper than it has ever been, thanks to the efforts of SpaceX and other private companies. However, it’s still expensive.

The use of more advanced thermoelectric materials will result in costs dropping significantly, opening the door for more satellites and other economy-boosting technologies. Additionally, it will improve the defense and offense systems that operate in orbit.

Medical Use

The medical sector could leverage these materials to improve a variety of treatments. For one, they could help muscle strain and burn patients recover. They could also help create more effective and durable medical equipment.

Clean Up

Environmental scientists could leverage this tech to help convert waste energy into usable power. Engineers globally tend to seek out how to create closed-loop manufacturing processes that recycle all waste into the process. This tech could help make that goal easier.

Thermoelectric Materials Researchers

Research into the thermoelectric materials study was hosted by the Institute of Science and Technology Austria (ISTA). The first author of the report is Shengduo Xu. Additionally, Maria Ibáñez, Abayomi Lawal, and Sharona Horta helped to bring this game-changing tech breakthrough to light.

Companies Leading Innovation in Thermoelectric Materials

Several companies have dominant positions in the thermoelectric materials sector. These companies play a vital role in the automotive, aerospace, defense, medical, and energy markets. Here’s one company that could leverage the thermoelectric materials study data to improve their ROIs.

TE Technology (TEL -0.75%) entered the market in 1941 under the name Aircraft and Marine Products (AMP). The company sought to provide electrical connectors to the aerospace and marine sectors. Since that time, it has expanded operations into a variety of sectors, including thermoelectric materials creation research, development, and more.

TE Connectivity Ltd. (TEL -0.75%)

Today, TE Technology is a leading provider of thermoelectric cold plates, liquid coolers, and thermoelectric coolers. It currently has +84k employees and offers products in 140 countries. The manufacturer has secured a reputation for producing high-quality and reliable products that meet industry-specific guidelines.

TEL is a strong addition to your portfolio. It has a 52-week range of $137.61 – $159.98 with a market cap of $45.71B. These factors, plus its proven history in the market, make TE TEchnologies worth looking into for anyone seeking a reliable thermoelectric materials stock.

Thermoelectric Materials – Change is on the Way

The full effects of this new thermoelectric materials manufacturing process won’t be felt for years. However, there are lots of ways in which this technology could improve the lives of people globally. For now, the technology is set to undergo additional testing as the engineers seek to make the process as flexible as possible.

Learn about other cool Additive Manufacturing Breakthroughs Now.

Latest on TE Connectivity

Study Reference:

1. Xu, S., et al. (2025). Interfacial bonding enhances thermoelectric cooling in 3D-printed materials. Science, 387, 845–850. https://doi.org/10.1126/science.ads0426