The Challenge of Powering Advanced Medical Implants

Improving the human body, or replacing defective parts, has been a goal of medicine as long ago as the first crude prosthesis of antiquity. Progressively, as mechanical components become more complex, the idea of replacing parts of the body became increasingly popular among science fiction enthusiasts, leading to the idea of cyborgs, people that would be half-human, half-machine.

To some extent, we could argue this is already happening, with surgeries like pacemaker implants or hip surgeries done routinely and supplementing issues in the heart muscle or articulation of the patients, improving them with metallic implants.

As neural implants and other advanced medical implants are becoming a likely reality in the upcoming decade, we are indeed getting closer than ever to creating true cybernetic bodies.

There is however still a recurring issue for most medical implants: power supply. Pacemakers make do with very small batteries because they need only very limited power levels. But implants like neural chips will likely require much more energy.

Traditional wireless charging methods, such as electromagnetic induction and radio frequency-based systems commonly used in smartphones and earbuds, face several challenges.

They can be vulnerable to issues like short transmission distances, low energy efficiency in biological tissues, and vulnerability to electromagnetic interference.

Another method might become possible, according to the work of researchers at the Korea University, Korea Institute of Science and Technology (KIST), Sungkyunkwan University (SKKU – South Korea), Yonsei University (South Korea), and the University of California.

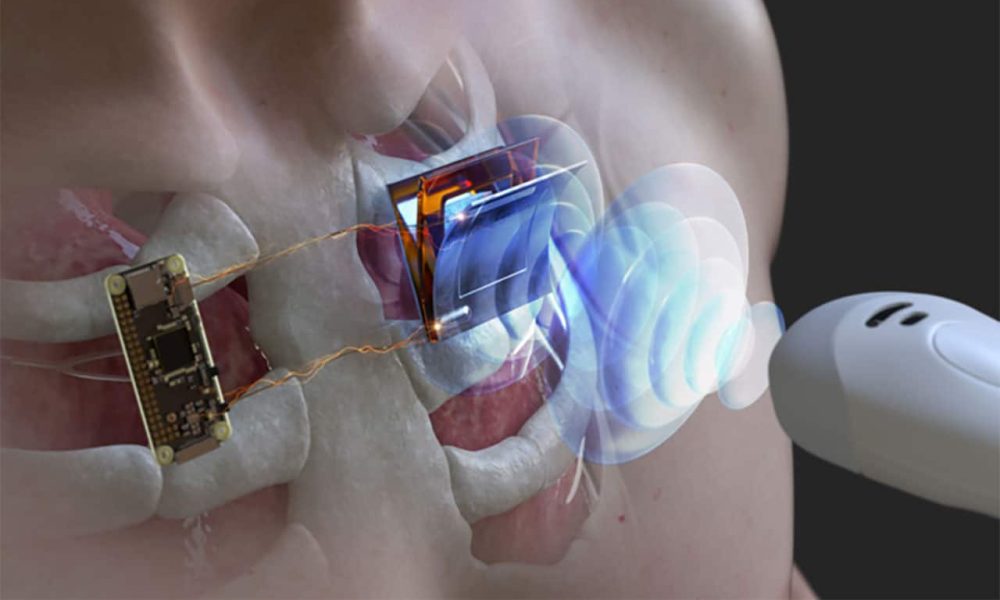

They developed a way to recharge medical devices wirelessly using ultrasounds instead. They published their discovery in Advanced Materials1, under the title “A Body Conformal Ultrasound Receiver for Efficient and Stable Wireless Power Transfer in Deep Percutaneous Charging”.

Why Wireless Energy Struggles to Penetrate Human Tissue

Electronic implantable medical devices (IMDs) are used in therapeutic applications of diseases or injuries, such as neurostimulation therapy and cardiovascular curing/monitoring.

They need regular surgery for battery replacement, which can lead to patient complications such as surgical site infections, biofilm formation, and high healthcare costs.

Some methods look to use the ambient energy of the body, like that of blood sugar to power these devices.

For some applications, the power requirements make such options unrealistic. For future applications like neural implants, this is even less likely to work, which would keep them very invasive.

Remote transfer of energy with electromagnetic or radio wave systems penetrates poorly into biological tissues and can cause unwanted side effects.

Photovoltaic wireless energy transfer is also unsuitable due to issues with low light penetration inside tissue and thermal tissue damage.

In contrast, ultrasounds are well tolerated by biological tissues and can penetrate deeply without causing damage, which is why they are routinely used for diagnostic purposes, including on pregnant women.

How Ultrasound Enables Wireless Implant Charging

Thanks to its long history of use in diagnostics, ultrasound already benefits from a large body of medical studies and norms determining the safe energy levels of ultrasounds that can be used (the FDA defines this as a maximum of 0.72 W per square centimeter).

Two types of devices can convert ultrasound to electricity: piezoelectric (US-PENGs) and triboelectric nanogenerators (US-TENGs).

US-PENGs have been developed for powering electronic implants, but commonly rely on lead-based piezoelectric ceramics, which are often rigid and may pose toxicity concerns.

It is why the researchers focused instead on US-TENG technology.

This biocompatible-covered device, with a thickness of 0.4 mm, achieves a high charge density suitable for powering electronic devices up to ≈6 cm deep at noninvasive ultrasound intensities.

How It Works

Thin polymeric films were used to create a fully flexible US-TENG, with layers of plastic material piled on each other, including acrylic or poly-(methyl methacrylate) (PMMA).

Source: Advanced Materials

Perfluoroalkoxy alkanes (PFA) were used for their triboelectric properties under mechanical energy. A nano-scale layer of electrode was deposited to maintain the unique properties of the PFA film.

A robust layer of polyurethane (PU) and polyvinylidene fluoride-trifluoroethylene, and calcium copper titanate (P(VDF-TrFE)pol/CCTO) was also used to maximize the electric charge production.

Source: Advanced Materials

Testing the Ultrasound-Powered Implant in Real Conditions

The entire device was then encapsulated in a polydimethylsiloxane (PDMS) solution for waterproofing.

This flexible US-TENG was tested for performance in water, polymer/hydrogel, and porcine tissue.

The first practical application would be to deploy this device in a pacemaker so that there is no more need for extra surgery to change the battery of the device.

Source: Advanced Materials

In parallel, the biocompatibility of the P(VDF-TrFE)/CCTO composite in terms of cytotoxicity and genotoxicity has been confirmed, verifying it is as safe in practice as previous studies had claimed.

The energy generation was precisely measured using a laser vibrometer, checking for the vibration of the device. This confirmed a 44% enhanced gain of the US-TENG compared to that reported last version of the similar category technology.

Source: Advanced Materials

Ultimately, they tested the efficiency of the system depending on ultrasound intensity, distance, and angle of the ultrasound source, determining if it could be used in realistic conditions for a medical device in the human body.

It confirmed relatively low ultrasound intensity, distance as deep as 4-8 centimeters (1.5-3 inches) and a relatively wide range of angles could work.

Source: Advanced Materials

Ensuring Flexibility and Durability of Medical Implants

Another challenge of implantable medical devices is that they ideally need to be very flexible, because the human body is not a robotic frame and organs move, especially the cardiac muscle.

This is why the researchers not only used flexible materials but also measured if they stayed efficient enough when bent.

Source: Advanced Materials

They found that it lost a little bit of energy generation when bent in one direction, but even gained some when bent in the other direction. The increase in energy generation was due to enhanced trapping of ultrasound waves in the bowl-shaped device and increased wave collisions on the device’s surface.

This anyway demonstrated that the device could bent without damaging or losing its energy-generating properties.

“Through this research, we have demonstrated that wireless power transmission technology using ultrasound can be applied practically.

We plan to conduct further research for miniaturization and commercialization to accelerate the practical application of the technology.”

Dr. Sunghoon Hur – Researcher at KIST

Final Thoughts: Next Steps for Ultrasound Implant Tech

Medical devices that could be recharged wirelessly would be a tremendous improvement for millions of patients globally.

This would also lift the limitation of more ambitious implant ideas that have so far been constrained by the lack of a realistic energy supply sufficient to perform the task. It could include implants delivering medicine directly into the bloodstream, monitoring specific chemicals, neural implants, etc.

This implant technology could be quickly deployed, with only 0.4 mm thickness, strong flexibility, good biocompatibility, and ease of manufacturing without rare exotic materials.

The technology could even find applications beyond medical devices, as it could as easily be used for recharging underwater drones without needing contact, removing the need for creating waterproof electric chargers.

Investing in HealthTech

Koninklijke Philips N.V.

Koninklijke Philips N.V. (PHG -0.28%)

Philips is a well-known small electronics consumer brand (shavers, electric toothbrushes), equally active in healthcare. For example, it was the #1 for MedTech patent filing in Europe for 2022.

It is active in connected medical products, from wearables to imaging, respirators, or medical robots.

The company is also active in semiconductors (including maglev technology) and high-tech/robotics/automation, with each activity sharing a common technological base.

Source: Philips

Philips offers wearables for cardiac, respiratory, and activity metrics. Its sensors can be integrated into smartwatches, health monitors, medical patches, and activity trackers.

Philips’s expertise in biocompatible sensors, semiconductors, and wireless solutions could make it a leader in advanced medical implants with wireless charging.

For medical devices, Philips favors a partnership solution, where it develops for third parties their connected IoT (Internet of Things) medical devices fully compatible with the rest of Philips’ solutions. In that context, it offers its clients prototyping, regulatory advising, end-to-end product development, and industrial-scale production.

This makes Philips a technology-focused company and a likely candidate for quickly integrating innovations into existing medical devices. In total Philips’s devices were directly affecting 1.8+ billion people.

The company wants to create a fully integrated digital healthcare environment, where sensors match devices, and then use multiple connectivity solutions to integrate into the Philips HealthSuite Cloud solution and allow for in-depth data analytics.

Source: Philips

As a MedTech industry supplier, often manufacturing for other brands, Philips is not as visible in the sector as other, more prominent companies. However, it is an expert in building high-performance electronic devices and sensors, often pushing the boundaries of what’s possible in its niche in healthcare and wearables.

With wearables and medical electronics increasingly integrated into healthcare and medical protocols, Philips’s Healthcare segment will likely grow as part of the conglomerate.

Latest Koninklijke Philips N.V. (PHG) Stock News and Developments

Study Reference:

1. Iman M. Imani, Hyun Soo Kim, et al. A Body Conformal Ultrasound Receiver for Efficient and Stable Wireless Power Transfer in Deep Percutaneous Charging. Advanced Materials. Volume37, Issue19. May 12, 2025