The Department of Energy in the United States Government defines the all-important task of Direct Air Capture technology as a “form of Carbon Dioxide removal that takes CO2 from ambient, or still, air. The separated CO2 can then be permanently stored deep underground, or it can be converted into products.”

According to available estimates, the direct air capture market size is set to witness phenomenal growth in the years to come, from more than US$23.59 million in 2022 to over US$614.07 million in 2028. It translates into a CAGR of more than 72%, a growth of nearly 30 times in six years.

But what drives this growth for DAC technologies? Removing the carbon dioxide serves the purpose of bringing down global temperature. Carbon dioxide traps heat by absorbing sunlight that reradiates off the Earth”s surface in the form of infrared waves. Unlike oxygen and nitrogen gasses that do not interfere with infrared waves, Carbon Dioxide soaks up the infrared energy.

As part of this soaking-up process, the infrared energy goes through vibrations and gets re-emitted back in all directions. About half of that energy goes out into space, and about half of it returns to the Earth as heat, contributing to the “greenhouse effect,” according to scientists.

Removing carbon dioxide from the atmosphere would help us get rid of the imminent menace of global warming, the rise in temperature worldwide.

While there are many ways to combat this threat, direct air capture stands out because of its advantages in terms of its impact on the Earth’s resources.

For instance, the use of energy in this technique is ‘non-trivial.’ According to estimates, reaching 7-9 million tonnes per year of capture capacity in the U.S. by 2030 would use 0.3-0.4% of today’s U.S. electricity generation.

This technology does not require encroaching on arable land. Its use of water may also come down notably with the development of solid sorbent DAC systems.

The benefits of DAC systems and their potential to benefit the planet have inspired many to develop innovative and optimized DAC solutions. In recent times, one company that has consistently done commendable work in this field is Climeworks. Most recently, it launched its latest facility: Mammoth.

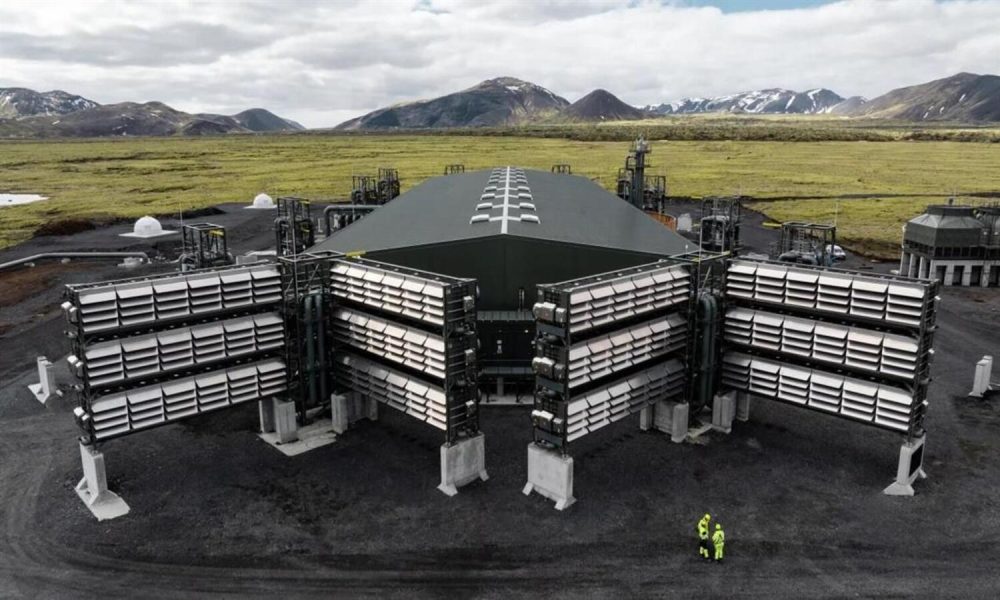

In the following few segments, we will look into what the facility is all about, which, located in Iceland, is claimed to be about ten times bigger than Climeworks’ predecessor plant in Orca.

Climeworks Mammoth Facility: What Does it Plan to Achieve?

The primary goal behind setting up the Mammoth facility was to meet the growing demand for more DAC projects. The company claims that the new facility would help it scale up its capacity ‘from thousands of tons to tens of thousands per year—an important milestone on the way to megaton capacity by 2030 and gigaton by 2050.’

Before delving deeper into understanding how Climeworks plans to carry out this task, let us look into a few more operational aspects to better understand the pretext of its scale and ambition.

The project is currently in commission and continues with its ramp-up vision. Located in Hellisheidi, Iceland, the facility’s annual capacity, as per its design, could reach as high as 36,000 tons of CO₂. While the facility, at its most basic level, would help provide engineering and operational experience for Climeworks’ 10x scale-up, it would add value by helping to develop the supply chain and bringing additional high-quality carbon removal capacity to the market.

The facility broke ground 18 months back, on 28th June 2022, to be precise. At present, the company reports that the plant’s infrastructure is successfully in place, with 90% of the systems operational, including that of storage partner Carbfix.

While speaking about the vision that drove the capacity-building exercise, Christoph Gebald, co-founder and co-CEO of Climeworks, said:

“Based on most successful scale-up curves, reaching gigaton by 2050 means delivering at megaton scale by 2030. Nobody ever built what we are building in DAC, and we are both humble and realistic that the most certain way to be successful is to run the technology in the real world as fast as possible and relentlessly deploy it.”

Further elaborating on what the plant signifies and its implications, so to speak, Jan Wurzbacher, co-founder and co-CEO of Climeworks, said the following:

“Having the core infrastructure in place and operational within just 18 months is a proof point of Climeworks’ ability to scale up quickly, with breakneck development cycles, on its path to gigaton capacity by 2050.”

But how does it plan to travel this route from megaton to gigaton? Let us try to understand.

How Will the Facility Function?

The Climeworks Mammoth facility has a processing hall at its center, which is used to process and condition the captured carbon dioxide before its underground sequestration. The process involves purifying and condensing the carbon dioxide before it is dissolved in water and sequestered underground by Carbfix, where it will turn into stone by the mineralization method. Apart from its operational units, the process hall will also have control rooms, offices, and a visitor center.

Commensurate with the capacity it is expected to handle, the Mammoth facility will have 72 collector containers to capture CO₂ from the air, while Orca consists of eight collector containers.

Additionally, the Mammoth facility also hosts a maintenance hall that aims to improve efficiency when maintenance work is needed.

Speaking about the facility’s operational philosophy, Douglas Chan, the COO at Climeworks, said the following:

“It illustrates very well Climeworks’ approach to spearheading the DAC industry: continuous acceleration while bringing to life the most rigorous operational standards.”

Several other companies are equally active in the field of DAC. In the coming segments, we will discuss a couple of such companies.

#1. Aircapture

The unique functioning of Aircapture involves installing modular Direct Air Capture (DAC) units on its customers’ manufacturing sites, creating a direct supply of clean CO2 in their production process. The company claims that commercializing atmospheric carbon dioxide has emerged as the most effective, scalable solution to improving the environment and the economy.

It has adopted a hyper-local approach to its functioning, which mitigates supply chain risks and eradicates the conventional market’s carbon footprint. Among the factors that make Aircapture distinct are its increased reliability, enhanced quality standards, reduced cost, and cleaner products with substantially reduced emissions.

Aircapture’s formulated solutions make it market-ready for a range of application scenarios, including beverage manufacturing, greenhouse agriculture, and more. For instance, it is capable of producing beverage-grade liquid carbon dioxide with low oxygen content at various volumes and production schedules.

It can help replace the emission-intensive raw material required to manufacture synthetic fuels with high-quality, clean carbon dioxide. Aircapture also assists in producing carbon dioxide at its customers’ growing facilities, helping customers meet their daily demand cycle and enhance crop yields.

Aircapture’s carbon dioxide is permanently injectable into concrete blocks or ready-mixed concrete, enhancing the standards of the prevailing curing methods.

Like the Mammoth project, Aircapture is also involved in carrying out studies and experiments that help leverage waste heat and decarbonized energy to geologically sequester carbon dioxide from the atmosphere.

Finally, the Aircapture liquid carbon dioxide is also convertible into dry ice, which meets the needs of retail, transportation, and logistics customers. Dry ice is famous for aiding the shipment of perishable goods and for other industrial uses.

In April 2022, Aircapture, along with carbon dioxide conversion company OCOchem and other partners, won a $2.93 million grant from the U.S. Department of Energy to design and engineer an integrated carbon dioxide capture and conversion plant co-located at Nutrien’s Kennewick Fertilizer Operations plant in Kennewick, Wash.

Speaking about the grant and its benefits, Matt Atwood, the founder and CEO of Aircapture, said:

“Our modular, on-site technology that takes CO2 from the air and puts it directly into our customers’ production processes addresses climate challenges while bringing value to our customers and is a perfect fit for this project with Nutrien.”

#2. Greenlyte Carbon Technologies

Another company that has done significantly good work in the DAC space is Greenlyte Carbon Technologies. Founded in 2022 by two serial entrepreneurs and a highly experienced DAC researcher, Greenlyte, located in Essen, draws heavily from its surrounding ecosystem that comprises leading technical universities and global chemical, industrial, and energy giants.

In the operational year 2022-23, Greenlyte completed building the first continuous cycle prototype and the 100-tonne DAC demonstrator.

Its vision for the future includes building a robust, efficient, and profitable operation at a meaningful scale by 2027. By 2035, the company wants to complete the task of ‘platformization,’ making robust, efficient, and profitable operations at a meaningful scale a reality. And by 2050, Greenlyte wants to scale its yearly production to 100 MT and become a global leader in the field of DACs.

One of Greenlyte’s primary advantages that makes it a fit case for DAC leadership is its low-energy, low-capex process for carbon dioxide capture and utilization. The gas is derived from the gas streams, the ambient air, to be specific. The subsequent conversion of carbon dioxide and hydrogen leads to the derivation of hydrocarbons that add value to the process and make the technology profitable.

Greenlyte further optimizes its technology by adopting a fully cyclic approach, where the used absorbent is regenerated in the electrolysis and subsequently used for absorption. Several of the process benchmarks, including absorption in a liquid sorbent solution, precipitation as hydrogen carbonate, and desorption by electrolysis, have Greenlyte’s patent applied to them.

In March 2024, Greenlyte Carbon Technologies closed a €10.5m pre-series A round. In addition to the large participation of all investors, namely Earlybird Venture Capital, Green Generation Fund, Carbon Removal Partners, and Board member Dr. Udo Jung, Partech joined the investor group.

The funding validates the traction Greenlyte has managed to earn recently in the form of partnerships and high-value offtake agreements. The company won two grants from the European Fund for Regional Developments and has now raised over €20m in equity and grants combined since its inception 18 months ago.

While explaining the importance of the funds raised, Florian Hildebrand, CEO and co-founder of Greenlyte, said, With the new funds, we will be able to grow our team from 30 to 50 people, allowing us to perform technology development and deployment in parallel with our expedited go-to-market, accelerate our scaling, and drive down costs more rapidly. The round is proof of our ambition to build a global DAC champion fast.”

The Future with More Efficient Direct Air Capture Technologies

Governments worldwide have realized the benefits of Direct Air Capture technologies. As a result, they have started supporting and encouraging DAC projects in the best ways they can.

For instance, the Department of Energy in the United States has designated as many as three of its offices, Fossil Energy and Carbon Management, Clean Energy Demonstrations, and the Advanced Research Projects Agency-Energy, to the task of supporting direct air capture research, development, and demonstration. This research has many aspects, including exploring the science and technology behind materials, chemicals, and biochemical and geological processes associated with the capture, conversion, and sequestration of CO2.

One of the most popular initiatives in this space has been the Carbon Negative Shot initiative—a call for innovation in carbon dioxide removal pathways that will capture CO2 from the atmosphere and store it at 1 billion ton scales for less than $100 per net metric ton of CO2-equivalent.

Efforts like these, combined with investments in the private sector, would definitely help make significant progress in not only setting the bar high but also making the bar accessible to industry and carbon dioxide producers worldwide.

Click here for a list of the best carbon capture stocks.