MIT Breakthrough Makes Rigid Materials Flexible With Metamaterials

Material sciences is the domain of better understanding materials at the microscopic, often atomic level, in order to make them better. The most common goal is to make a material stronger than in its classical form, be it steel, glass, or ceramic.

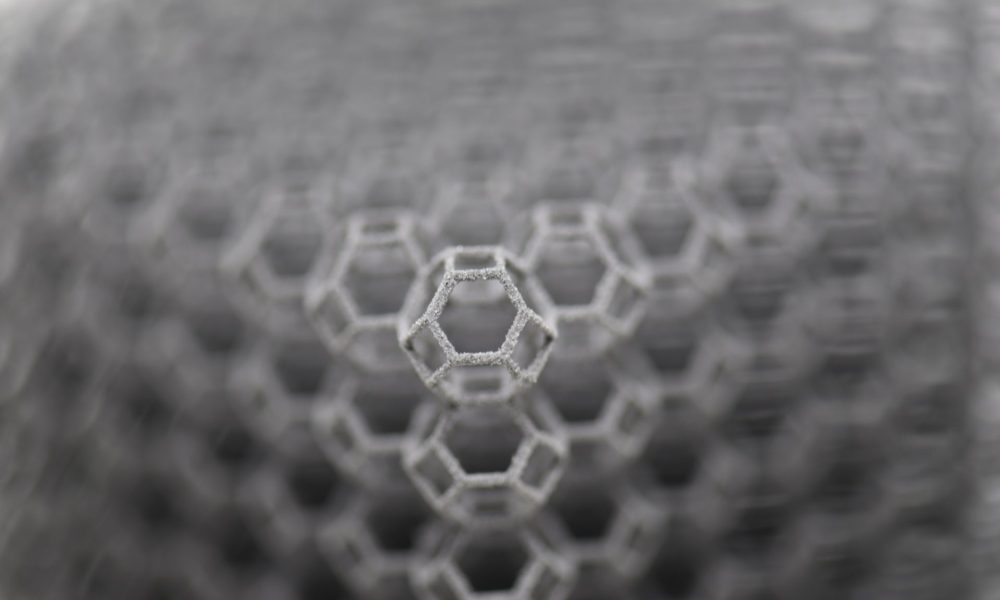

Metamaterials bring it one step further, by changing the structure of the material, giving it different characteristics than the properties of the base materials it is made from. This is most often achieved by creating repeating patterns of precise shape, geometry, size, orientation, etc.

Source: MIT

Here too, most of the research that has been done has concentrated on making the final product stronger than its base component, with potential super steel, carbon fiber, silk, and other materials that could be used in body armor, construction, or futuristic projects like space elevators.

A new type of metamaterial is now being invented, making otherwise stiff and rigid elements flexible. This discovery was made by MIT researchers and published in Nature Materials1, under the title “Double-network-inspired mechanical metamaterials”.

How Metamaterials Outperform Traditional Materials

The creation of regular micro-structures in a controlled way can lead to improved performance of a material compared to its base component. This can be affected by many different properties, like electromagnetic, acoustic, structural strength, thermal, etc.

In general, this comes as a trade-off. For example, stronger materials are generally getting stiffer, which can reduce their practical use.

So it is sort of a revolution that the MIT researchers are creating, by mixing methods, making a material stiffer and stronger, but also making it more flexible at the same time.

“We realized that the field of metamaterials has not really tried to make an impact in the soft matter realm.

So far, we’ve all been looking for the stiffest and strongest materials possible.”

Carlos Portela – Associate Professor at MIT.

Stronger and More Flexible: Solving the Metamaterial Trade-Off

So far, most metamaterials are made using a method similar to 3D printing, producing microscopic struts and trusses.

Source: ETH Zurich

Instead, the MIT researchers developed an architecture of interwoven springs, or coils, inherently more flexible.

In their initial experiment, they used a material like plexiglass, which should be very rigid, and assembled it “normally”. When woven into a metamaterial, it became soft and springy, like rubber.

“We are opening up this new territory for metamaterials.

You could print a double-network metal or ceramic, and you could get a lot of these benefits, in that it would take more energy to break them, and they would be significantly more stretchable.”

Carlos Portela – Associate Professor at MIT.

This was a good start, as it could use strong materials and make them soft and flexible. It was, however, a little too successful, as although the material was stretchy, it was “a little too soft and compliant”.

Hydrogel-Inspired Design Boosts Flexibility and Durability

Another exceptional material is hydrogel, a type of soft, stretchy, Jell-O-like compound that is composed mostly of water and a bit of polymer structure. Some hydrogels are even natural, like gelatin, for example.

MIT researchers have already found ways to make hydrogel tougher, while keeping its soft and stretchy abilities. They do so by combining multiple polymer networks with very different properties, such as a network of molecules that is naturally stiff and one that is inherently soft.

So the researchers adapted this concept to their plexiglass metamaterial. They mixed a stiff and strong classical metamaterial using a grid-like scaffold of struts and trusses, together with a pattern of coils that weave around each strut and truss.

Both networks of material were made at the same time, using a high-precision, laser-based printing technique called two-photon lithography.

Source: LiqCreate

How Double-Network Metamaterials Perform at Any Scale

The newly invented double-network metamaterial was then tested at different sizes. Some samples were made with the component measuring several square microns, some up to several square millimeters.

They then measure the resulting strength and flexibility using high-speed cameras when pushing the material to its limit.

Source: MIT

The double network proved able to stretch 3x its own length, which is 10x farther than a conventional lattice-patterned metamaterial.

“Think of this woven network as a mess of spaghetti tangled around a lattice. As we break the monolithic lattice network, those broken parts come along for the ride, and now all this spaghetti gets entangled with the lattice pieces.

That promotes more entanglement between woven fibers, which means you have more friction and more energy dissipation.”

Carlos Portela – Associate Professor at MIT.

It is this spreading of the energy that is the key driver of the metamaterial’s flexibility, as an initial crack is unlikely to go straight through and quickly tear the material.

How Strategic Defects Make Metamaterials Even Tougher

Counter-intuitively, they also discovered that it was possible to make it even stronger by poking holes into the lattice.

This defect allows for even more energy dissipation and increases the overall resilience of the final product.

“You might think this makes the material worse. But we saw once we started adding defects, we doubled the amount of stretch we were able to do, and tripled the amount of energy that we dissipated.

That gives us a material that’s both stiff and tough, which is usually a contradiction.”

James Utama Surjadi – Postdoctoral student at MIT

This allowed the research team to develop a theoretical framework to better predict the behavior of such metamaterials.

Real-World Uses for MIT’s Flexible Metamaterials

Such a blueprint will be useful in designing tear-proof textiles and fabrics.

Flexible semiconductors, electronic chip packaging, and durable yet compliant scaffolds on which to grow cells for tissue repair could also benefit from this technology.

Another option would be to deploy this concept of mixing different metamaterials together (struts and trusses together with coils) to what are currently brittle materials. It could give them both more flexibility and more resilience at once.

The same idea could be used to add new specs to existing materials, for example, making them naturally reactive to their environment.

“So far we’ve talked of mechanical properties, but what if we could also make them conductive, or responsive to temperature?

For that, the two networks could be made from different polymers that respond to temperature in different ways, so that a fabric can open its pores or become more compliant when it’s warm and can be more rigid when it’s cold.”

Carlos Portela – Associate Professor at MIT.

Investing in the Future of Commercial Metamaterials

DuPont

DuPont de Nemours, Inc. (DD +0.46%)

DuPont is a massive chemical company with many important branded chemicals, such as Kevlar, Styrofoam, Nomex (fire protection), Great Stuff (construction adhesive), etc. Its advanced polymer research and protective material brands could position it to benefit from double-network metamaterial technologies.

DuPont is an ancient corporation with a complex history of acquisitions, and more recently, a series of spin-offs.

Source: DuPont

These spinoffs have separated from DuPont the departments of nutrition and bioscience, partially sold to Corteva Biosciences (CTVA +0.64%), titanium products forming the Chemours Company (CC +1.74%), and mobility.

It will also separate from its electronic chemicals business in November 2025, but retain the water segment (membranes and filters for water purification and desalination), contrary to earlier plans.

Source: DuPont

This will leave DuPont a much more focused company, with a core activity in advanced polymers for water purification and protection equipment, as well as advanced materials for aerospace, healthcare, and electric vehicles.

Source: DuPont

DuPont is a truly international corporation, with high demand for specialty chemicals in water purification and industrial manufacturing.

The sectors served by DuPont chemicals are also very varied, including construction, water purification, the electronics industry, automotive, aerospace, healthcare, green energy, and industrial production.

Source: DuPont

The strong presence of DuPont in protective equipment and the established position with the Kevlar brand, a high-performance polymer, should help it adapt new forms of metamaterials into commercial products.

In any case, as new technologies are growing, as well as water consumption, so is the demand for the advanced chemicals produced by DuPont.

Latest on Dupont

DuPont de Nemours (DD) Earnings Expected to Grow: Should You Buy?

zacks.com • April 25, 2025

INVESTOR ALERT: Pomerantz Law Firm Investigates Claims On Behalf of Investors of DuPont de Nemours, Inc. – DD

accessnewswire.com • April 24, 2025

INVESTOR ALERT: Pomerantz Law Firm Investigates Claims On Behalf of Investors of DuPont de Nemours, Inc. – DD

accessnewswire.com • April 23, 2025

DuPont to Showcase Overlaminate Innovations at ISA Expo in Las Vegas

zacks.com • April 22, 2025

Bronstein, Gewirtz & Grossman, LLC Encourages DuPont de Nemours, Inc. (DD) Shareholders to Inquire about Securities Investigation

accessnewswire.com • April 22, 2025

Studies Referenced:

1. Surjadi, J.U., Aymon, B.F.G., Carton, M. et al. (2025) Double-network-inspired mechanical metamaterials. Nat. Mater. https://doi.org/10.1038/s41563-025-02219-5