Why Ceramics Matter in Aerospace

Aerospace materials often use rare metals, for example, titanium, rhenium, iridium, or tungsten (follow the links for a dedicated investment report about each of these rare technological metals). This gives the planes and spaceship frames, turbines, reactor exhausts, and other critical components the resistance to heat and mechanical stress required by the extreme conditions required for flying.

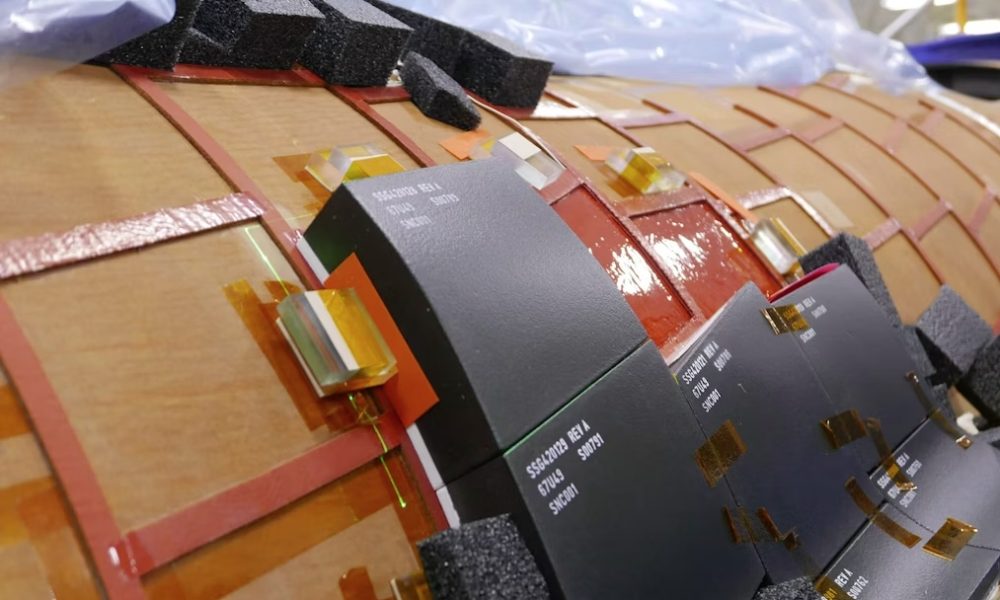

Another category of material used is ceramics. These materials are different from metal in that the initial components are often relatively ordinary minerals. However, the right combination of minerals produced in the right conditions can have extraordinary properties. For example, most of the tiles that are able to handle the extreme heat of reentry into the atmosphere of spaceships are made of ceramics.

Source: NASA

Ceramic materials are not melted (like metal) but sintered, a process more similar to how glass is produced. Only some of the compounds melted/vitrified hold together unmelted particles.

Source: Hengko

Additionally, sintering requires placing the raw materials in a furnace that can reach temperatures of at least 2,200 °C (4000°F). It is a very energy-intensive and time-consuming process.

Four researchers at North Carolina State University might have discovered an alternative method for the production of high-performance aerospace ceramics, using lasers.

They published their findings in the Journal of the American Ceramics Society1, under the title “Synthesis of hafnium carbide (HfC) via one-step selective laser reaction pyrolysis from liquid polymer precursor”.

The Role of UHTCs in Aerospace Engineering

Why Traditional Ceramic Manufacturing Falls Short

Ultrahigh-temperature ceramics (UHTCs) are a class of materials designed to withstand extreme environments, due to their exceptional thermal stability, high melting points (>3000°C), high strength, and resistance to oxidation and thermal shock.

Of these materials, hafnium carbide (HfC) stands out as one of the most promising candidates, with a melting point >3900°C, as well as strong hardness, elasticity, and thermal conductivity.

Unfortunately, HfC has so far been difficult to produce and very expensive as a result. Large-scale production of HfC of consistent quality has especially been a problem, with significant microstructural inconsistencies leading to structural defects.

New techniques are being considered, notably furnace-based polymer-derived ceramic (PDC), but they only result in a poor liquid-to-ceramic yield of 11% to 21%.

In addition to these production issues, these methods are not compatible with additive manufacturing (3D printing). So they are only compatible with simple shapes doable with molds, like bulk, cylindrical, or cubic geometries.

How Laser Sintering Transforms Ceramic Production

Many 3D printing methods already leverage laser for creating complex shapes otherwise impossible with traditional molding and forging techniques. This is radically changing how jet engine turbines and rocket engines are being produced.

The researchers considered the approach using a selective laser reaction pyrolysis (SLRP) method.

Source: Journal of the American Ceramics Society

Instead of the multiple steps of furnace methods for ceramic making, this puts in one step the polymer conversion to ceramic and pyrolysis.

The liquid precursor can be applied to the surface of the structure and then sintered with the laser.

The laser used in the demonstration is relatively powerful for a laser (a 120W (CO2) gas laser), but also very low energy compared to traditional furnaces used for hafnium carbide production.

Testing Ceramic Additives for Laser Processing

Two additives were also tested to see if the process could be made even more efficient: dicumyl peroxide (DCP), a thermal activator; and benzophenone (BZP), a photo-activator.

DCP had at best a minimal effect, while BZP significantly reduces energy reflection, enhancing the precursor’s absorption of infrared energy.

Source: Journal of the American Ceramics Society

Electronic microscope pictures showed a uniform distribution of spherical and faceted HfC grains across all temperature conditions (1700°C, 1800°C, and 2000°C). Larger grain clusters at higher temperatures indicate a denser ceramic.

Source: Journal of the American Ceramics Society

“This is the first time we know of where someone was able to create HfC of this quality from a liquid polymer precursor”

Cheryl Xu – Professor of mechanical and aerospace engineering at North Carolina State University.

Laser Sintering vs. Furnace: Which is Better?

Besides saving energy, the laser sintering developed here is much more efficient. Furnace-based sintering achieves a ∼20%–40% crosslinked liquid-to-ceramic yield at best, while laser-based sintering achieves a ∼50%–55% yield.

This is also a lot quicker, as furnaces require hours or even several days, while the laser performs the task in seconds or minutes.

The peak temperature of the laser is also higher, allowing for more complex geometries, better coatings, thin films, and work in only one step.

“Lastly, our technique is relatively portable. Yes, it has to be done in an inert environment, but transporting a vacuum chamber and additive manufacturing equipment is much easier than transporting a powerful, large-scale furnace.

Cheryl Xu – Professor of mechanical and aerospace engineering at North Carolina State University.

Emerging Applications for Laser-Sintered Ceramics

So far, HfC has only been possible to apply on substrates that could handle the extremely hot temperature of a furnace for a lengthy period of time.

The laser process invented here is a lot less destructive, creating a much wider realm of possible applications.

“Because the sintering process does not require exposing the entire structure to the heat of the furnace, the new technique holds promise for allowing us to apply ultra-high temperature ceramic coatings to materials that may be damaged by sintering in a furnace.”

Cheryl Xu – Professor of mechanical and aerospace engineering at North Carolina State University.

For example, laser sintering could be used to create high-quality HfC coatings of carbon-fiber-reinforced carbon composites (C/C):

“The HfC coatings on C/C substrates is particularly useful because, in addition to hypersonic applications, carbon/carbon structures are used in rocket nozzles, brake discs and aerospace thermal protection systems such as nose cones and wing leading edges.”

Cheryl Xu – Professor of mechanical and aerospace engineering at North Carolina State University.

The smaller size and portability of the system could also have a long-term effect on the technology potential. For example, any in-situ production of aerospace materials on a Lunar or Martian bases would require relatively small and lighter equipment.

Investing in Laser Technologies

II-VI Marlow / Coherent: A Laser Tech Leader

Coherent, Inc. (COHR +1.07%)

Coherent is a large industrial conglomerate with 26,000+ employees and a leader in laser technology. It resulted from the merger of advanced material II-VI Marlow with laser maker Coherent.

The company is an expert in advanced materials used in lasers, optics, and photonics, such as indium phosphide, epitaxial wafers, and gallium arsenide.

It grew largely thanks to multiple acquisitions over the last decade, from $600M in revenues in 2013 to $4.7B in 2024

The company derives 29% of its revenues from lasers directly, with the rest linked to associated equipment like optical fiber, and electronics. The instrumentation category mostly includes life sciences and medical applications.

Source: Coherent

The presence of the company in advanced materials like thermophotovoltaics (which we discussed in a previous article), silicon carbide, lasers, and electronics helps it benefit from structural trends like the growth of precision manufacturing, additive manufacturing (3D printing), electrification, and renewables energies.

The company has recently separated its silicon carbide business into a new entity, owned at 75% by Coherent, with the rest owned equally by its partners Mitsubishi Electric (bringing silicon carbide power IP) and Denso (bringing its activity as an automotive supplier on electrification and power semiconductors).

This is because silicon carbide is increasingly its own technology, mostly used in high-power applications like EVs, batteries, and renewable energy.

Coherent is a leader in LIDAR and 3D-digital sensing, including for self-driving applications, biotech Next Generation Sequencing (NGS) Flow Cells, and lasers for semiconductor manufacturing. It expects its main markets to grow at 8-20%.

Source: Coherent

The other potential new applications of lasers like direct energy weapons, photonic computing, nuclear fusion, and spacetech could all equally help sustain the long-term growth of the company.

Overall, Coherent is as close as it can get to a “pure play” publicly traded laser company for investors interested in the sector, with strong vertical integration and 3,100+ patents protecting its innovations.

Latest Coherent (COHR) Stock News and Developments

Study Referenced

1. halini Rajpoot, Kaushik Nonavinakere Vinod, Tiegang Fang, Chengying Xu. Synthesis of hafnium carbide (HfC) via one-step selective laser reaction pyrolysis from liquid polymer precursor. Journal of the American Ceramics Society.14 May 2025https://doi.org/10.1111/jace.20650