Graphene & Batteries

Battery technology is quickly evolving, with dozens of competing alternative chemistries challenging the dominance of lithium-ion batteries, whose discovery was rewarded by a Nobel Prize in Chemistry in 2019.

One such alternative is batteries using graphene.

This is because graphene is a “wonder material”, made of a single layer of carbon atoms. This gives it extraordinary electric properties. We explained more about graphene, as well as other “2D materials” like borophene and goldene in “2D Materials, Like Graphene, Open New Frontiers In Material Sciences”.

Electric properties are not the only characteristics which make graphene exceptional. It is also remarkable for its thermal conductivity, making it able to transfer heat extremely quickly.

Source: GMG

This thermal property could prove to be transformative for battery technology and, paradoxically, graphene could help keep lithium-ion batteries the dominant battery tech over alternative chemistries, including graphene-based batteries.

This could happen thanks to a discovery by researchers at Swansea University (UK), in collaboration with Wuhan University of Technology and Shenzhen University (China). They revealed their results in a scientific paper published in Nature Chemical Engineering under the title “Large-scale current collectors for regulating heat transfer and enhancing battery safety”.

Graphene Limitations

On paper, graphene is a wonder material that should revolutionize many industries, from battery manufacturing to anything using electricity, including computers and solar panels, and even concrete and nanorobots in our bloodstream.

In practice, graphene suffers from a few limitations:

- Manufacturing at scale: Scotch tape applied to a piece of graphite was enough to discover graphene. But much more complex methods like Chemical Vapor Deposition (CVD) are required for mass production.

- Costs: most production methods and applications to existing devices are mostly small-scale or bespoke, and 2D materials have stayed rather expensive. Actual price can greatly vary depending on purity, with for example graphene ranging between $20-2,000/kg.

Of course, the 2 problems are linked, as it is the small scale of production that increases costs. So far, it has severely hindered the mass adoption of graphene, making most of the promises of this material still unfulfilled, despite its discovery 20 years ago in 2004.

The ability to produce graphene-based material in large volumes is key to both reducing costs and allowing for industrial-scale applications.

This is a purely manufacturing and technological issue, as graphene is made of carbon, an abundant and cheap material. So it does not suffer from the problem of rare materials like for example hydrogen-producing catalysts using rare metals like platinum or palladium.

As such, graphene has the potential to truly revolutionize our energy systems, without hitting limits from resource depletion when deployed en masse.

Making Kilometers Of Graphene

This issue of large-scale production is what the researchers in the aforementioned paper claim to have partially solved.

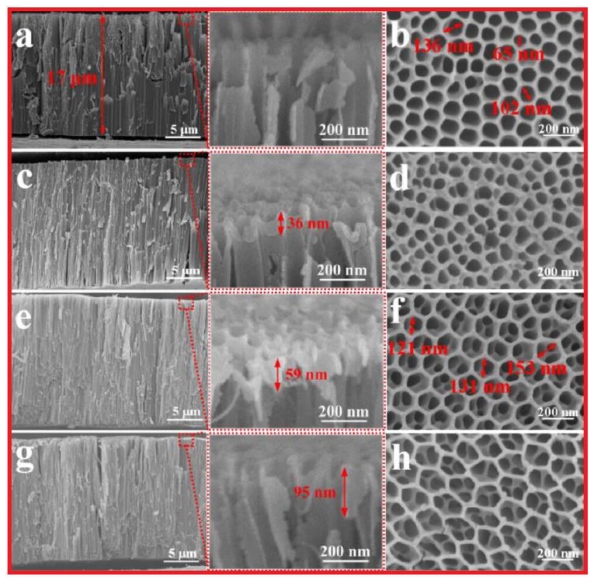

The researchers’ publication “details the first successful protocol for fabricating defect-free graphene foils on a commercial scale”.

The method explained in the scientific paper can be used to create graphene foils in lengths ranging from meters to kilometers.

Even in a laboratory setting not designed for mass production, they managed to create a 200-meter-long graphene foil with a thickness of 17 micrometers.

This foil is also remarkably resistant and was demonstrated to retain high electrical conductivity even after being bent over 100,000 times.

So it can be safely assumed that it will be possible to deploy it in flexible electronics, industrial manufacturing, and other applications where the graphene is used to deploy powerful currents.

What Can Graphene Foils Do?

Lithium-ion batteries are vulnerable to a key risk, called thermal runaway. This happens when excessive heat accumulates in a part of the battery, often leading to battery failure with dangerous fires or explosions.

This issue is one of the key reasons many researchers and battery companies are looking beyond lithium-ion with alternative chemistries like sodium-ion. Many alternative solutions are being explored, for example, gel electrolytes.

Thermal runaway mostly happens at the battery’s current collectors, where the most power is concentrated. In current lithium-ion batteries, current collectors are usually made of aluminum or copper.

The graphene current collectors developed by the research with their graphene foil can display a thermal conductivity as high as 1,400.8 W m−1 K−1. For reference, this is almost 10x higher than copper and aluminum-based current collectors.

Source: Nature Chemical Engineering

Implication For Lithium-Ion Batteries

Because the graphene foil shows a very fast heat dissipation, it eliminates the risk of local heat concentration when the current is flowing.

In turn, this removes the risks of aluminothermic and hydrogen-evolution reactions which are the critical steps leading to propagation of the battery failure and fire hazard.

“Our dense, aligned graphene structure provides a robust barrier against the formation of flammable gases and prevents oxygen from permeating the battery cells, which is crucial for avoiding catastrophic failures,”

Dr Jinlong Yang, co-lead author

Maybe more importantly, the method is already proven to be deployable with mass manufacturing of the graphene foil. So it could be quickly integrated into existing battery manufacturing processes.

“This is a significant step forward for battery technology. Our method allows for the production of graphene current collectors at a scale and quality that can be readily integrated into commercial battery manufacturing. This not only improves battery safety by efficiently managing heat but also enhances energy density and longevity.”

Dr Rui Tan, co-lead author

Future of Graphene Foil Applications

The researchers are already looking at ways to reduce the thickness of the graphene foils and further enhance their mechanical properties.

They are also looking at how the graphene foil could help design better flow batteries and sodium-ion batteries, in collaboration with another research team at Swansea University, under Pr. Serena Margodonna’s leadership.

We previously discussed honeycomb lithium-ion batteries that remove the risk of battery failure from dendrite growth. If thermal runaway also can be suppressed thanks to graphene foil, this could make lithium-ion batteries much more safe and durable than the current version.

Source: Chemistry Europe

This overall follows the pattern of most innovations in one niche of battery technology to be usable in other designs, helping feed the quick progress of the industry.

(You can also learn more about battery technology in our articles “The Future of Mobility – Battery Tech” and “The Future Of Energy Storage – Utility-Scale Batteries Tech”.)

Investing Into Battery Tech

Lithium-ion batteries have already changed the world several times, from allowing people to carry advanced electronics everywhere to powering cars with electricity only.

They might still do so again, or other types of batteries, by allowing for a 100% renewable power grid or allowing for airplane electrification when reaching a high enough energy density.

You can invest in battery-related companies through many brokers, and you can find here, on securities.io, our recommendations for the best brokers in the USA, Canada, Australia, the UK, as well as many other countries.

If you are not interested in picking specific battery companies, you can also look into biotech ETFs like Amplify Lithium & Battery Technology ETF (BATT), Global X’s Lithium & Battery Tech ETF (LIT), or the WisdomTree Battery Solutions UCITS ETF, which will provide a more diversified exposure to capitalize on the growing battery industry.

Or you can check our articles “Top 10 Battery Stocks To Invest In” and “Top 10 Battery Metals & Renewable Energy Mining Stocks”.

Battery Companies

1. Veeco

Veeco has been a major supplier of equipment to the semiconductor manufacturing industry since its foundation in 1945. Its machines are used in producing advanced EUV chip making, 5G antennas, hard drives, LIDAR, LEDs, power electronics for EVs, etc.

Source: Veeco

The company’s main technological focus is the same CVD process used for borophene and some graphene production, or more precisely, MOCVD (Metal-Organic Chemical Vapour Deposition).

Source: Veeco

As a leader in this niche segment of the semiconductors industry, Veeco could be a good candidate to bet on the rise of more CVD applications.

Such growth could be stemming from the growing usage of graphene, tungsten, and borophene, as we progressively get better at manipulating matter at the atomic level. This includes graphene thin film, but also potential graphene semiconductors, superconductors, etc.

It will also likely benefit from the massive trends of digitalization, AI, and electrification, whether it massively uses 2D materials or not.

2. Graphene Manufacturing Group (GMG)

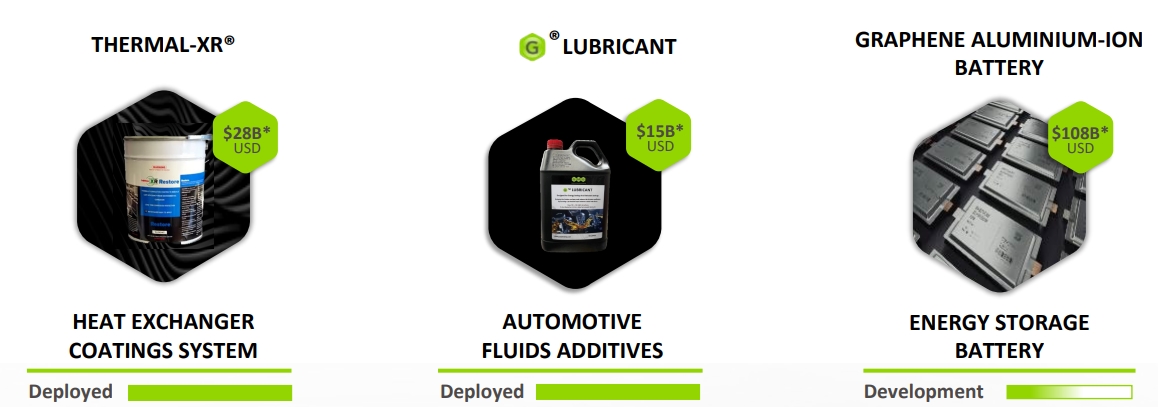

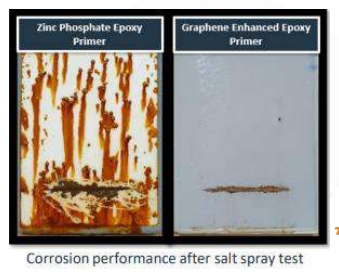

GMG is a graphene producer that has focused its product offering on already demonstrated graphene-based products like heat coating and lubricants.

This makes GMG a good option for investors looking for direct exposure to the graphene market and a company already active in mass-producing graphene and improving the current production method.

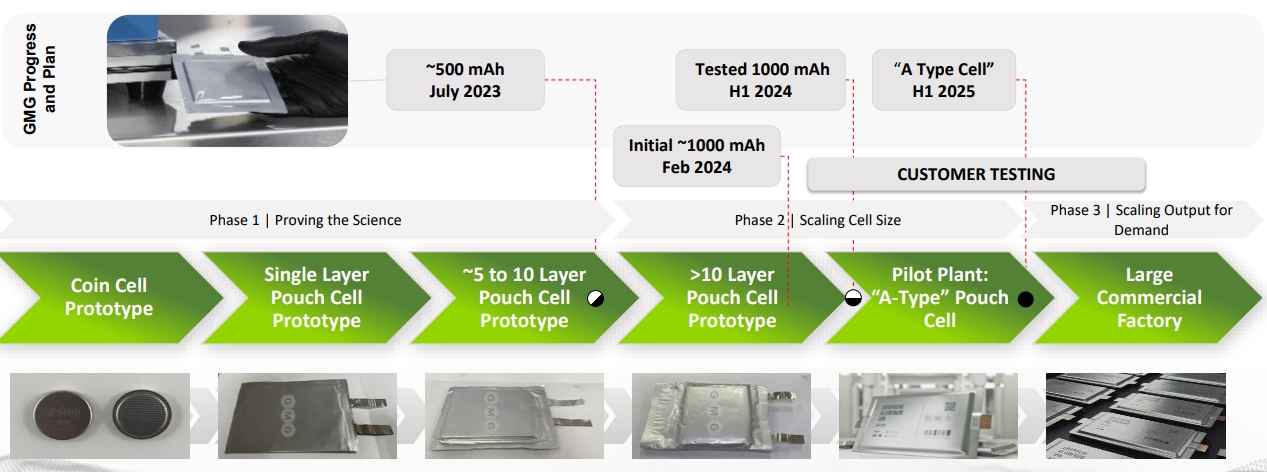

Source: GMG

Some further applications could be the creation of graphene semiconductors (see “Graphene Semiconductors – Are They Finally Here?”), or even room-temperature superconductors. Graphene coating could also find use in batteries and for hydrogen pressure vessel technologies.

Source: GMG

GMG produces its graphene from methane + hydrogen, which differs from most of its competitors, who produce it from graphite natural deposits. This allows for higher purity, more scalability, and low-cost production.

The company launched its first production facility in Australia in 2023, with up to 1 million liters of heat exchanger coating production per year.

The next step for the company will be its battery technology based on graphene aluminum ion, with a density of 290 Wh/kg, 60x faster charging than lithium-ion batteries, 3x the battery life, and a better fire hazard profile.

Source: GMG

This entry into the battery market might be a big gamble for GMG, but also gives it a unique perspective on the future market that could open for graphene, including in EV and other power-related applications.