As electric vehicles (EVs) continue to rise in popularity and adoption, Donut Lab has unveiled its new in-wheel electric motor that comes with better efficiency than conventional electric motors at a much lower cost.

Claiming to be the most powerful in the world, this next generation of in-wheel electric motors from Donut Lab promises unmatched torque and power density with minimal weight.

The new donut motors, according to Donut Lab, are “the most advanced, powerful, and versatile in-wheel motors ever created.”

Donut Lab is a new electric powertrain startup that was spun out of Verge Motorcycle, which pioneered electric motorcycles. This subsidiary was announced just a few months ago to expedite EV development by bringing all the components needed for such a vehicle onto a single platform and making it available to all industry operators.

With Donut Lab, the Finnish company aims to take advantage of the huge potential that it sees in the electrification of mobility. The global electric transportation market is actually projected to be worth over a trillion dollars in the coming years.

Talking about the motivation behind its move, Lehtimäki, CEO of Donut Lab and co-founder and CTO of Verge Motorcycles, noted that when developing the world’s most advanced electric motorcycle, they learned just how difficult and slow it is to build EVs using traditional mechanisms.

Traditional powertrain systems make electric vehicles not only expensive to manufacture and maintain but also increase their complexity and weight while reducing vehicle performance.

This is due to the involvement of many components from different equipment manufacturers. Moreover, these components are not designed to work together, which means integration takes up most of the time.

“We decided that if we were able to solve this, we would change the entire automotive industry.”

– Lehtimäki

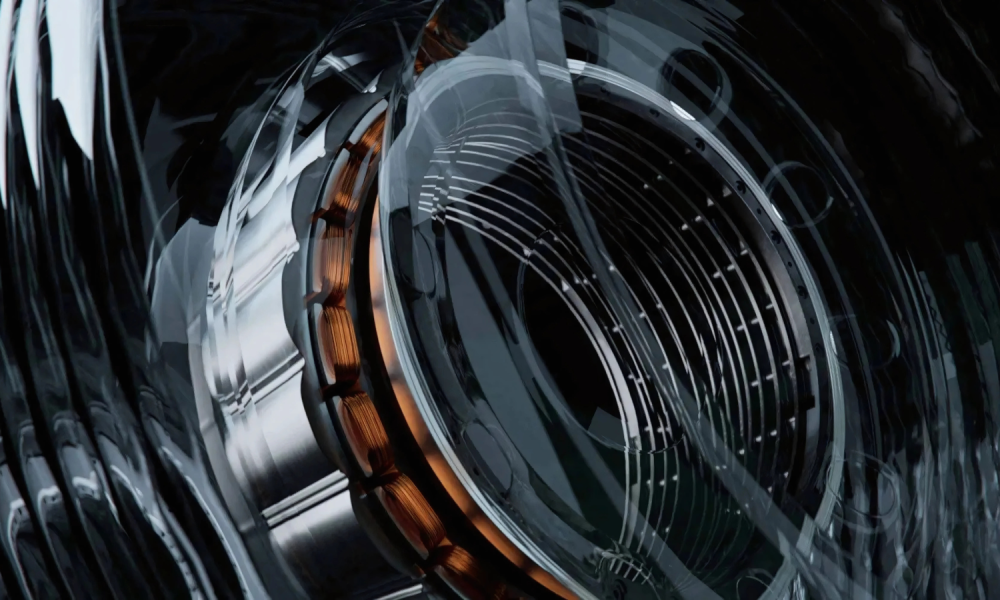

Now, one of the main components of this technology platform is the donut-shaped motor. This flagship innovation combines maximum torque and power density with a lightweight design. Installed directly in the wheel, it removes the need for a drivetrain, making vehicles more affordable and simpler to manufacture.

This way, Donut Lab aims to significantly speed up the EV development cycle while reducing the resource requirements by up to 95% and time to just a matter of months.

“We want to set a new standard for what electric transportation can achieve. The Donut platform creates entirely new opportunities for almost any industry.”

– Ville Piippo, Product Director of Donut Lab and Chief Product Officer at Verge Motorcycles

In addition to motors, the platform also offers high-performance battery technology optimized for the most demanding conditions. The modular battery systems deliver high-performance energy tailored to maximize efficiency, scalability, reliability, and adaptability.

Then there’s the purpose-built Brain, seamlessly powering next-generation vehicle intelligence. It comes with sensor compatibility, cutting-edge connectivity, and a comprehensive software platform designed for intelligent EVs, enabling advanced connectivity, data optimization, and real-time updates.

All these components are designed to work together without any manual integration, as such simplifying and accelerating the application development.

With this modular platform, Donut Lab envisions a future where customers will be able to just select the components that they need from a catalog and then link them together with standard connectors with ease and swiftly.

The platform suits a variety of applications ranging from compact SUVs, semi-trucks, and hypercars to helicopters, heavy-lift drones, robots, marine vessels, and space mission all-terrain automobiles.

Its products have actually been gaining a lot of traction among manufacturers. Latvian startup Oruga is one that used the Donut Lab platform to develop its Unitrack, which is a combination of a snowmobile and a motorcycle that offers an off-road solution for all kinds of landscapes. Meanwhile, the Australian startup Hyper Q Aerospace has used it in its electric, remote-controlled RotorHawk rotorcraft designed to support the military and emergency responders.

The aim is to redefine the future of mobility with revolutionary in-wheel motor technology and a platform where every component works together seamlessly to deliver unmatched efficiency, control, and performance.

A Family of Electric Motors

This year, Donut Lab took concrete steps towards its ambitious plan to incorporate electric drive components into next-generation electric machinery of all styles and sizes.

The company released the first batch of its all-electric motors at the annual CES 2025 show in January. It was a whole family of five donut motors that could be placed directly into the tire. With each motor, Donut Lab cuts mass boosts torque and improves the overall performance of the target machine. According to Lehtimäki:

“After a long wait, we finally get to present the next-generation version of the most important component of our technology platform. Its performance capability is out of this world. Our donut motor has now also expanded into an entire motor family, which includes size options and performance classes for various uses.”

The ring-shaped e-engines have all the central mass carved out, which would have resulted in less power and torque, but the company has achieved exactly the opposite.

To start with, Donut Lab’s flagship “Automotive” motor boasts 630-kW power, which is pulled from a motor weighing a mere 88 lb, giving it a power-to-weight ratio of 15.75 kW/kg or 9.6 hp/lb. Even if these are just preliminary estimates that can see a drop in production, the power-to-weight ratio is certainly a cause of excitement.

When it comes to other motors, they also give solid figures in power density ranging between 2 and 7.1 kW/kg, just not as exciting or best as the Automotive unit, which is optimized for high performance and reducing mass in the wheels and connection points.

Yet to be revealed, the semi-truck motor has been optimized for endurance, weighing 40 kg and delivering 200 kW of power and 3000 Nm of torque. The motor for the motorcycle is optimized for lightness which reduces the weight in the wheel and swingarm, giving it 150 kW power and 1200 Nm torque at 21 kg weight.

Its scooter motor meanwhile focuses on improving efficiency and reducing active material usage, providing it with 15 kW power, 300 Nm torque, and 8 kg mass. The drone motor has a compact package, yielding 3 kW power, 20 Nm torque, and 1.5 kg weight.

The torque density of these lower-output motors ranges between 13.3 and 75 Nm/kg.

Coming back to the ‘Automotive’ spec, while its power-to-weight ratio is attention-grabbing, the torque density is just as much noteworthy if not more, which according to Donut Lab simply blows away any competition. The Automotive motor has a 4,300 Nm or 3,172 lb-ft of torque for a density of just under 108 Nm/kg. However, it is not the true output; rather, it is the rotor output.

Compared to Donut Lab’s motor, yielding 845 bhp and 3,172 lb-ft, the ‘Dark Matter’ e-motor from the Koenigsegg Gemera yields 811 bhp and 922 lb-ft. Interestingly, both the motors weigh the same, i.e., 40 kg. But while the Gemera is a hybrid, the all-electric Rimac Nevera R’s two rear motors, out of a total of four, produce around 600 bhp each.

With its high density and low weight standard, Donut Lab motors will also be able to overcome some major hindrances that are posed by in-wheel motor configurations in getting adopted in production vehicles.

This includes the unsprung weight, which in-wheel motors add significantly. However, in donut motors, this is counterbalanced by their sheer power and torque.

Unsprung weight in a motor vehicle is the mass of components not supported by the suspension system and as such most susceptible to road shock and cornering forces. This includes the wheels, tires, brakes, and axles. Minimizing the unsprung weight is key to making steering and handling performance as well as ride quality.

As Donut Lab CEO Mark Lehtimaki explains, it has been the great unsprung mass that has been the primary reason why not everyone has used motors integrated with the tire in their vehicles.

“[But now] through the torque and power density we’ve now achieved, the relative weight of the motor is so small that the unsprung mass is insignificant.”

– Lehtimaki

Donut Lab has even stated that the unsprung mass is “imperceptible.” In addition to the low weight of the units, all these motors from Donut Lab remove the need for transmission hardware like the driveshaft and axles. This cuts down the complexity, weight, and costs. The in-wheel configuration of the motor further frees up space, allowing for the designing of more spacious interiors.

Powering the Next-Gen Electric Mobility

The donut motors are being presented as “the best electric motor in the world by any parameter” with the kind of “incredible performance” that is currently not available with any other technology. They will be delivering the highest power and torque both per kilogram and per dollar with Lehtimäki declaring it to be “a really magical piece of technology.”

According to the official website of Donut Lab, its electric motors with “insane performance” will power the next-gen electric vehicles. With these hole-in-the-middle motors, traditional powertrains will be made a thing of the past.

For a compact SUV, the company claims that its technology needs 75% fewer components as it eliminates almost 120 parts. The tech can also cut the vehicle’s weight by 85kg, which could be as much as 1,100kg for a truck. It can further save up to eight hours of assembly time per vehicle and achieve a materials cost saving of €2,000.

The direct drive design of donut motors not only makes vehicles lighter, more agile, and increases design flexibility but also reduces wear and maintenance by eliminating unnecessary transmission components. This way, the donut motor extends lifespan and ensures customer satisfaction with reliable, long-term performance.

Meanwhile, less heat generation reduces the need for additional cooling systems while enhancing energy transfer efficiency, which means greater power output and lower energy consumption.

Donut Lab’s direct drive technology further boasts of enabling control at a millisecond frequency, which allows for precision adjustments in real time. Direct power delivery to wheels also means the motor provides enhancements in stability, accuracy, and traction control.

Overall, the donut motor provides an efficient, elegant, and powerful framework that promotes innovation and makes advanced vehicle development accessible.

It is, however, unlikely that normal vehicles will be deployed with the kind of power the flagship motor offers as they simply don’t need it. Verge Motorcycles is already using Donut Lab’s smaller motors. Heavy-duty EVs, however, are in need of reduced overall weight and increased payload. So, such powerful motors can be expected to be deployed in trucks first.

If these motors go mainstream, Donut Lab expects their simple shape and reduced use of active materials to cut manufacturing costs by 50% compared to conventional electric motors.

The “elastic performance specification” of the company also means these motors can meet the specific power and torque demands of all kinds of existing as well as future projects.

The new family of motors “will change the way we build EVs,” predicts Lehtimäki.

Besides launching its motors at CES, Donut Lab also announced a partnership with Qt, a Finnish software company that has introduced an application for automating and streamlining the development of Human Machine Interface (HMI) for vehicles.

HMI is a set of systems, including touchscreens, buttons, voice control, and more, that allow drivers to interact with the vehicle. The HMI application is called Qt Accelerate, and it will be integrated into the Donut platform.

The application, Lehtimäki noted, is designed specifically for the automotive industry and provides an efficient and quick way to create HMIs entirely automatically. The Qt and Donut collaboration meanwhile will provide significant advantages to vehicle development and marks the first step in building a broader ecosystem for the Donut platform.

This allows the company to develop the world’s first no-code environment for vehicles to cut the number of errors, increase safety, and accelerate development work.

While the platform’s physical components are “already revolutionizing the automotive industry,” the new intelligent software layer will allow for the automatic integration of physical components.

In addition to this, Lehtimäki stated:

“[That Donut Lab is] now developing future software development solutions that will make vehicle development significantly more efficient and agile. At the core of all of this is advanced AI, and in the future, the AI features of the Donut platform will improve vehicle design, development, testing, and validation in unimaginable ways.”

Prominent Players in Electric Mobility

Electric vehicles, unlike conventional internal combustion engines that use petrol or diesel, make use of electricity as a power source for transportation. Most electric cars use one or more electric motors which are fed by a battery to generate propulsion. These electric motors convert electrical energy into mechanical energy for EVs to run as well as driving countless machines, processes, and electronic items.

With EVs offering the benefits of lower fuel costs, improved fuel economy, and reduced emissions, they have become the focus of companies, researchers, consumers, and governments alike.

In the world of EVs, the likes of Tesla (TSLA -6.34%) with its Full Self-Driving (FSD), BYD (BYDDF) with its blade battery tech and cost-effective EV production, and Hyundai Motor Group with its hydrogen EVs are advancing the EV space.

Meanwhile, BorgWarner (BWA +0.34%) (BWA) with its eAxles and integrated electric drivetrains, Siemens (SIEGY) with its compact motors, and Danfoss (DANF) with its high-torque motors are advancing motor tech.

Click here to learn how EVs can help save more than just earth.

So, let’s take a deeper look at a couple major players that are at the forefront of electric mobility.

1. General Motors (GM +0.28%)

The automaker is actively expanding its EV lineup and has been investing in advanced electric motor technologies. GM has a market cap of $47.15 billion with its shares trading at $47.40, down 11.04%. It has a P/E (TTM) ratio of 7.72 and a dividend yield of 1.01%.

General Motors Company (GM +0.28%)

For Q4 2024, the company recorded $215 million in net income and ended it with $30.3 billion in available liquidity and $127.6 billion in earning assets. Revenue for the quarter was $47.7 billion, while earnings per share was adjusted to $1.92. While the automaker stopped funding its Cruise Robotaxi business, it will refocus its autonomous driving business on personal vehicles. GM also noted that during the quarter, EVs reached targeted profitability on a production basis and expects a $2 billion to $4 billion improvement this year based on the 300,000 EV target.

2. Lucid Motors (LCID -2.89%)

This one is involved in luxury EVs with its compact, high-performance motors. Lucid has a market cap of $8.5 billion with its shares trading at $2.84, down 6.29%. It has a P/E (TTM) ratio of -2.12.

Lucid Group, Inc. (LCID -2.89%)

In Q4 2024, the company produced 3,386 vehicles and delivered 3,099 vehicles. For the full year, more than 9,000 vehicles were produced and 10,241 delivered, an increase of 7% and 71%, respectively, from 2023. Largely backed by Saudi Arabia’s Public Investment Fund, Lucid ended the third quarter with $5.16 billion in total liquidity, excluding a $1.75 bln stock offering and capital raise.

Conclusion

Electric vehicles have taken over the world with their advanced capabilities and are now leading the charge toward sustainable transportation. They are, after all, a clear and more efficient alternative to traditional fuel-powered cars that are still widely used. To drive EV adoption, technological advancement needs to make them more accessible and efficient.

One such area that is the focus of innovation is the electric motor, which sits at the core of every EV and determines everything from the vehicle’s efficiency to performance and driving experience.

As we shared today, Donut Lab has developed motors that push the boundaries of design and engineering to reduce cost, deliver higher power density, and make it easier and faster to develop EVs. Constant technological advances like these combined with collaboration among industry players and government support are key to enabling more affordable, efficient, and powerful EVs, hence, shaping the future of mobility.

Click here for a list of top EV stocks.