A team of engineers from Zhejiang Lab and Zhejiang University in China unveiled a novel direct laser writing method that leverages dual beams to improve accuracy. The upgraded system could enable engineers to make more resilient and powerful optics, memory systems, and more. Here’s what you need to know.

Direct Laser Writing

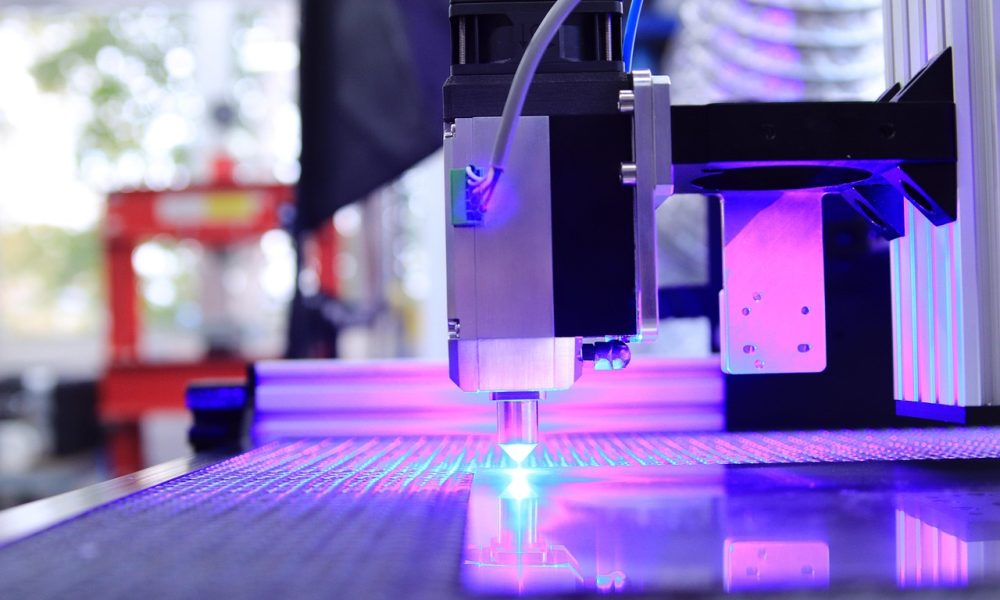

Direct laser writing or Multiphoton lithography is a manufacturing process that refers to utilizing lasers to induce precise 3D polymerization in materials. These beams enable engineers to make controlled markings and other damage to provide an exact optical response.

Impressively, these systems can produce intricate designs that are thinner than a human hair. As such, they’re ideal for the manufacturing of optical components and other precise equipment utilized in today’s electronics.

Problems with Current Direct Laser Writing Methods

Direct laser writing is a valuable manufacturing process used in multiple industries today. However, it has many limitations that have slowed further adoption and innovation. For one, the most common method utilizes blinds to interrupt the laser when not needed.

Sadly, this approach results in bleeding over from the laser photons during the process, reducing quality and the ability to scale down designs. Additionally, the bleed-over can produce unwanted exposure and reduce design accuracy.

Details of the Study

The engineers behind the Super-resolution direct laser writing via multiphoton and peripheral photoinhibition photolithography1 study released in Optics Letters, seek to usher in a new age of AR/VR and other advanced technologies. The study introduces a super-resolution 3D DLW approach that enhances performance considerably compared to its predecessors. This upgraded process could unlock the door for better VR, optics, computers, and much more.

Dual-Beam Optical Setup

The scientist introduced a dual-beam optical setup that utilized a 525-nm femtosecond laser as the excitation light source. This laser worked in tandem with a 532-nm picosecond laser. The latter beam is used to stop polymerization areas surrounding the laser-exposed region.

The choice to utilize a multiphoton DLW and DLW with peripheral photoinhibition provides engineers with significant benefits like added controllability. Specifically, the team needed to track and adjust laser intensity, focus, alignment, power fluctuation, drift, and memory effect to achieve the desired results.

Photoresist

The engineers created a photoresist that integrates PETA combined with a material called BTPOS. Notably, photoresists are light-sensitive materials that play a vital role in today’s microchips and other high-tech electronics. In this experiment, the primary purpose was to prevent cross-linking when creating nanoscale high-resolution line patterns.

Spatial Light Modulator (SLM)

The engineers fine-tuned everything utilizing a spatial light modulator. This piece of hardware is tasked with modulating the excitation and inhibition light. The fine-tuning was improved after the team added Zernike polynomials to the SLM. That step allowed the team to correct wavefront aberrations and stabilize the beams.

How the System Works

The upgraded DLW functions by using both lasers in tandem. First, the femtosecond laser imitates a 2700 ps delay switch before launching the picosecond laser. Notably, the lasers have slightly different optical paths as well. This approach enables high-resolution and precision prints on a nanoscale.

Direct Laser Writing Test

To test their theory, the engineers created several nanostructures. The team began by printing out nanoscale wood piles utilizing lateral rod spacing from 300 nm to 225 nm. Nanoscale wood piles are an ideal testing scenario as they demonstrate the complexity and intricacy of creating nanoscale designs where the lines must intersect and stack onto each other. Interestingly, the engineers set the fraction limited axial resolution of 320 nm, enabling some impressive results.

Source – Optica

Direct Laser Writing Test Results

The results prove that a system integrating a photoresist with a depletable photoinitiator and a radical quencher is capable of producing laser writing with unprecedented speed and resolution. Specifically, the device demonstrated 100-nm lateral resolution at 100 µm/s printing speeds. Notably, the printer’s accuracy only slowed slightly when sped up to 1000 μm/s.

Direct Laser Writing Benefits

There are many benefits to the upgraded direct laser writing system could introduce to the market. For one, it’s much faster than utilizing single laser methods. The ability to rapidly fabricate test or replacement parts is a big draw for this tech.

High-Precision

The upgraded DLW method will improve engineers’ ability to create and integrate complex optical elements. From satellites to the sensors on your phone, this technology should provide additional capabilities to many of the technologies you rely on a daily basis. Engineers will be able to make smaller and more accurate lenses and other devices.

Real-World Applications & Timeline

There are a host of applications for his technology. The demand for advanced optics remains on the rise. From the military to the commercial sector, engineers demand smaller, more accurate lenses and other components.

As such, this technology has the potential to revolutionize data storage solutions and photonic devices. Notably, the engineers predict strong commercial integration within the next 3-6 years.

Data Storage

Laser writing hard drives will get a major boost in capabilities when this technology becomes mainstream. These devices etch small markings that can be picked up and translated into data. The ability to make these lines smaller and more accurate opens the door for increased performance and capacity from future hard drives.

VR and AR

The VR and AR markets will see major upgrades utilizing this technology. Already, the team has discussed utilizing this tech to upgrade the optical waveguide devices used in VR displays. The enhanced units would provide high-resolution structuring coupled with precision and cost efficiency.

Photonic Device Manufacturing

This technology will drop the pricing of manufacturing microlenses, photonics crystals, micro-optical devices, and other high-tech devices. The ability to create nanosize etching consistently and at a lower cost than today’s options will drive innovation and help create even more powerful and resilient photonic devices.

Direct Laser Writing Researchers

Engineers from the Zhejiang Lab and Zhejiang University in China hosted the direct laser writing upgrade research. Specifically, a team led by Xi Liu, Qiulan Liu, Mengdi Luo, Liang Xu, Cuifang Kuang, and Xu Liu worked together to verify their findings. Now, the goal is to exceed speeds of 10 and 100 mm/s in the coming year.

Companies Leading Innovation in Laser Writing

Several firms rely on direct laser writing to produce their products and services. These companies play a vital role in their industries, providing high-tech solutions that help keep the economy growing.

From aerospace sensors to smart glasses and everything in between, DLW manufacturers are making a difference. Here’s one company that has secured a reputation as an innovative and well-positioned market leader.

Seagate Technology Holdings PLC (STX -1.81%) entered the market in 1979 as Shugart Technology, intending to provide high-performance storage options to the community. The firm rebranded into Seagate Technologies Holdings as part of its pivot towards advanced data storage solutions.

Seagate has been a pioneering force in the market. For one, it was the first company to introduce a 5.25 HDD in 1980 and dominated the HD market for most of that decade. The company has also boosted its positioning through a series of acquisitions, including Conner Peripherals in 1996. From there, the firm acquired Maxtor in 2006 and Samsung’s HDD business in 2011.

Seagate Technology Holdings plc (STX -1.81%)

Seagate Technology Holdings offers a wide selection of products to the market today. Specifically, they provide storage devices, systems, and services to individuals, all the way up to enterprises. The company could integrate the DLW study results and improve its products significantly in the coming years. As such, many analysts see STX as a strong “Add.”

Latest on Seagate Technology Holdings

Dual-Beam Direct Laser Writing Opens the Door for New Tech

The concept of utilizing a laser to prevent laser spill-over may seem a bit far-fetched, but this team has demonstrated that it works extremely well. Their printers have exceeded all previous nano printing capabilities in terms of accuracy and have proven that a dual-beam approach is a viable option.

You should expect to see this technological breakthrough lead to major enhancements across many industries in the coming months. For now, this team of engineers deserves some praise for their efforts.

Learn About Other Cool Nanotech Now

Studies Referenced:

- Liu, X., Liu, Q., Luo, M., Xu, L., Kuang, C., & Liu, X. (2025). Super-resolution direct laser writing via multiphoton and peripheral photoinhibition photolithography. Optics Letters, 50(5), 1675-1678. https://doi.org/10.1364/OL.50.01675