Solid-State Batteries To Achieve EV Domination

While lithium-ion batteries have become the dominant solution for EV battery systems, they suffer from a few limitations.

One of these is still not-so-great energy density, and another one is a safety issue linked to the growth of dendrites piercing the battery and the electrolyte sometimes catching fire.

Source: Nobel Prize

Both problems are expected to be alleviated with solid-state batteries, which remove the need for electrolytes and the risk of dendrites.

Toyota is forecasting the usage of these solid-sate batteries by 2027, and overall, it seems a solid candidate for the future of mobility.

Still, some issue persists, notably with the garnet-type solid electrolyte, also known as Li7La3Zr2O12 or LLZO (see below).

So it is good news that four researchers at McGill University in Canada announced that they created a new LLZO design that can deliver an increased amount of energy. They published their results in Cell Reports Physical Science in a paper titled “4.8-V all-solid-state garnet-based lithium-metal batteries with stable interface”.

Solid-State Electrolyte

LLZO

It is usually said that solid-state batteries do not need electrolytes. This is technically correct when referring to the liquid electrolyte commonly used in lithium-ion batteries.

But of course, any battery still needs some sort of bridge between the anode and cathode to function. There are three types of solid-state electrolytes (SEs): ceramic, polymer, and composite SEs (CSEs).

The composite solid-state electrolytes (CSEs) mix polymer SE with ionic conductive inorganic fillers like Li7La3Zr2O12 (LLZO) to facilitate lithium-ion transports.

While this method is ideal for high-voltage operation in dense batteries, it suffers from poor contact with the electrode, reducing the overall efficiency.

Porous LLZO

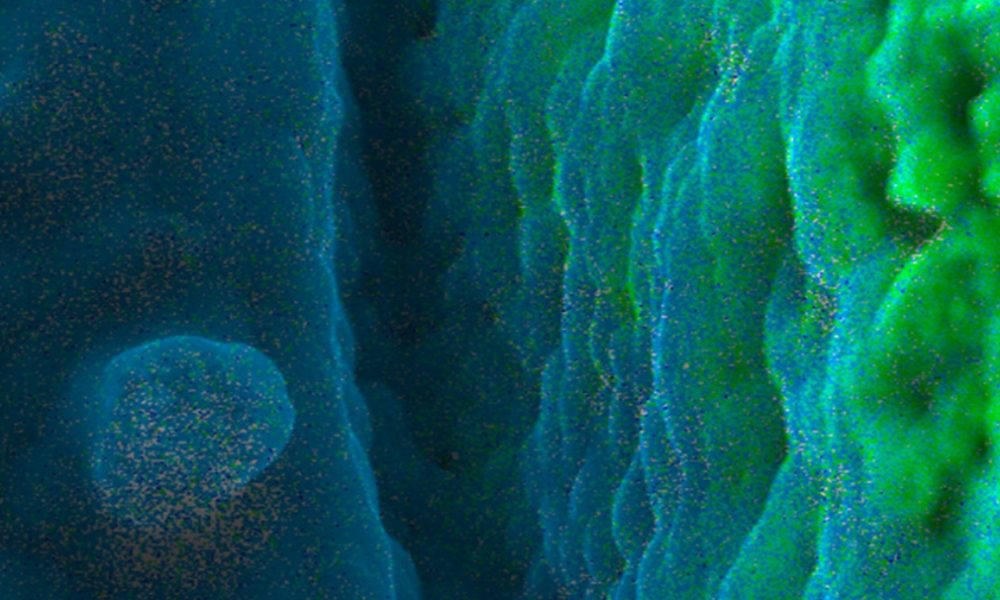

What the researchers discovered, is that the LLZO can be made of a porous ceramic membrane, instead of the usual sense plate. In more technical terms:

Here, we design a highly conductive and interface-friendly garnet-based composite solid electrolyte (CSE) comprising a cubic Li6.1Al0.3La3Zr2O12 porous framework and polyvinylidene difluoride (PVDF) with a three-dimensional continuous structure.

Visually, it translates into a very complex 3D structure full of small holes at the microscopic scale:

Source: Cell

This creates a lot of surface contact for the lithium-ion, while still offering a strong adherence to the electrode.

Source: Cell

More Stable & Durable Batteries

Solid-state batteries are overall a lot more powerful and energy-dense than lithium-ion batteries. But they have been difficult to manufacture at scale so that they can last many charge-discharge cycles without losing capacity.

So the researchers went on to test the batteries to see if the electrode interface they had created was as sturdy as they expected.

After 200 cycles, they studied it under a microscope and found no trace of degradation, like cracking, delamination, etc.

Source: Cell

Overall, the battery prototype demonstrates excellent resistance, especially against dendrite formation.

Li-Li symmetric cells based on the ceramic-based CSE can cycle stably for 1,000 h at 0.1 and 0.5 mA cm−2, indicating excellent electrochemical stability against Li-metal and even Li+ deposition (dendrite suppression).

Better Safety Profile

The drastically reduced dendrite formation, as well as the absence of flammable electrolytes, should help increase significantly the safety of lithium batteries.

Because the thickness of the ceramic-based CSE is only 125 μm, this also makes this technology very competitive to create very energy-dense solid-state batteries.

It should also be noted that while not simple, the technique used to create the improved LLZO does not require rare metals, rare machinery, or complex steps that are out of the ordinary in battery manufacturing.

Source: Cell

So overall, this should be an important step in boosting further the characteristics of solid-state batteries in all important aspects: stability, safety, energy density, and ease of production.

Are Solid State Batteries Winning?

It is not to say that solid-state batteries are certain to become the new standard for EV batteries in the coming years.

Lithium-ion batteries might be able to compete as well. This is mostly linked to improvement in the design, with similar nanopores helping in reducing dendrite formations.

Most notably, honeycomb batteries developed by battery manufacturing global leader CATL might reach a safety profile and energy density similar to some solid-state batteries.

Overall, it seems that a deeper understanding of battery material, especially at the micro- and nano-scale, and the uses of nanopores will be the way forward to keep improving battery performances and remove for good the risk caused by dendrite formation.

Investing Into Battery Tech

Lithium batteries have already changed the world several times, from allowing people to carry advanced electronics everywhere to powering cars with electricity only.

They might still do so again, or other types of batteries, by allowing for a 100% renewable power grid or allowing for airplane electrification when reaching a high enough energy density.

You can invest in battery-related companies through many brokers, and you can find here, on securities.io, our recommendations for the best brokers in the USA, Canada, Australia, the UK, as well as many other countries.

If you are not interested in picking specific battery companies, you can also look into biotech ETFs like Amplify Lithium & Battery Technology ETF (BATT), Global X’s Lithium & Battery Tech ETF (LIT), or the WisdomTree Battery Solutions UCITS ETF, which will provide a more diversified exposure to capitalize on the growing battery industry.

Solid State Companies

QuantumScape Corporation (QS +0.46%)

Long expected to be the one of the first companies to bring solid-state batteries to the market, QuantumScape has been at the forefront of the development of this technology.

QuantumScape batteries are using lithium metal, anode-fee batteries.

Anode-free batteries instead store the ions in an electrochemical deposit of alkali metal directly on the current collector. This allows for higher cell voltage, lower cell cost, and increased energy density.

Source: QuantumScape

(we also discussed the concept of anode-free batteries in the context of sodium batteries in “Anode-Free Sodium Solid-State Batteries Could Reduce Reliance on the ‘Lithium Triangle”).

QuantumScape has however regularly delayed the expected date of mass production of its batteries, dampening the initial enthusiasm of investors for the company.

This might be changing with a few key developments in 2023 & 2024:

- Improvement in consistency and quality of production.

- Improvement in packaging design, including tighter internal margins, thinner current collectors, and a slimmer frame.

- Shipped high cathode-loading unit cells to automotive OEM (Original Equipment Manufacturer) partners.

- Announced the launch of QSE-5, the company’s first commercial product, with a prospective launch customer in the automotive sector.

Overall, QuantumScape seems to be by far the solid-state company with the most mature technology, especially when it comes to the durability of the battery.

Source: QuantumScape

Deal With Volkswagen

More importantly, the company is showing real progress in establishing a partnership with Volkswagen, the 2nd largest automaker in the world.

In July 2024, QuantumScape signed with Volkswagen an agreement to collaborate on manufacturing battery cells based on QSE-5 design.

The license would allow PowerCo to manufacture and sell automotive batteries up to 40 GWh annually, expandable by an additional 40 GWh.

This is a non-exclusive, royalty-bearing IP license, allowing QuantumScape to keep selling to any other potential client.

Maybe more importantly to alleviate investors’ anxieties about the company, it will also give an initial royalty fee of $130M, credited against future royalties, paid by PowerCo, Volkswagen’s battery subsidiary.

This gives the company an additional 18 months of cash runways compared to previous guidance, going well into 2028 by now.

It should be more than enough time to ramp up production and start registering solid revenues.

So as long as QuantumScape batteries perform adequately, they should be able to find their niche in the market alongside batteries manufactured by larger companies like CATL, BYD, and Panasonic.

Considering that Volkswagen has likely extensively tested its own QuantumScape prototypes and studied the production ramp-up, the recent agreement seems quite a solid endorsement of the company’s technology.

Source: QuantumScape

Besides, the parallel 2027 Toyota’s deadline for commercialization of solid-state batteries seems to indicate that after many false starts, the technology is now reaching a point where it is mature enough.