A team of thinkers from the Grainger College of Engineering developed an Artificial Intelligence model that can accurately fingerprint 3D-printed parts. The AI examines key details that can’t be observed by the human eye and cross-references its findings with the specific details each 3D printer leaves.

The discovery could help to alleviate manufacturing, monitoring, and supply chain management woes, potentially saving companies billions. Here’s what you need to know.

Challenges in Supply Chain Verification

The complexity of today’s products means that their construction can require thousands of components, sourced from across hundreds of manufacturers. Sadly, this scenario has led to some problems, as ensuring manufacturers’ quality remains unchanged has proven to be a tricky task.

In a typical manufacturing agreement, both parties come to an understanding about key details of the product. These details can include exact processes, materials used, and factory procedures. Depending on the part and its purpose, it may not be easily noticeable that any changes were made for some time or until failure occurs.

Identifying the Source of a Part

In the past, the common methods used to ensure a part came from where it said it was made included very rudimentary approaches such as part labels, trackers, and even pressed-in serial numbers. These approaches could be easily seen, but we’re also easily copied, forged, and counterfeited. These problems led to manufacturers insisting on covert tags on some components.

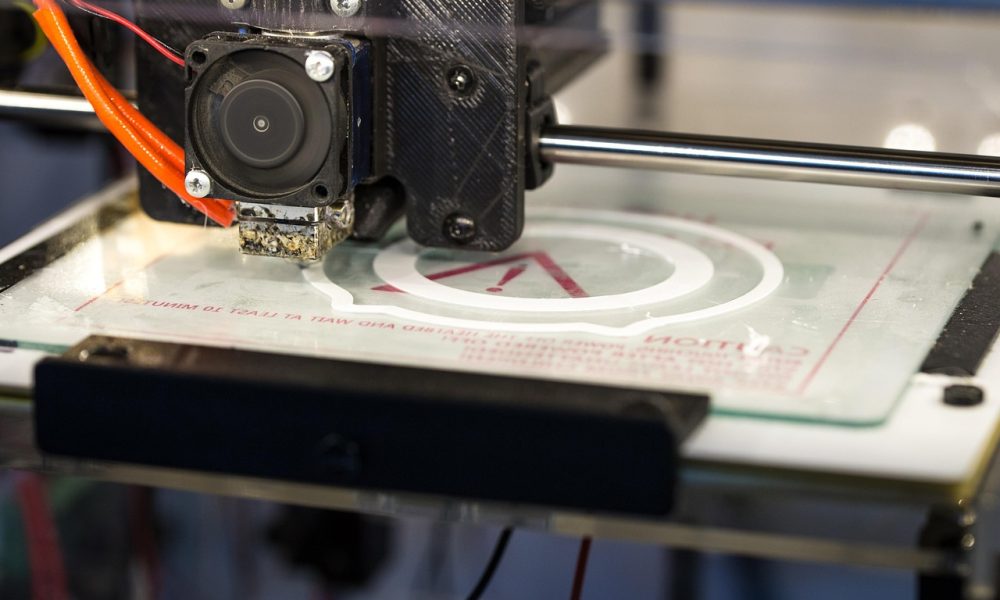

3D Printing and Its Vulnerabilities

The introduction of 3D printing changes the industrial process forever. This flexible manufacturing option made it easier for manufacturers to outsource components. At the same time, 3D printed parts are easier to alter and counterfeit.

There are more factors to manage and monitor when discussing additive manufacturing, including feedstock quality, process controls, and the type of machines used. Notably, any changes in these categories can lead to substandard part quality.

Traditional Approaches to Quality Control

Manufacturers have gone to great lengths to try and kick up their auditing processes. They may conduct more onsite visits and require additional markings to ensure the origin of products. However, the truth is that this approach has proven to be ineffective on a large scale.

In the past, human experts were called in to help determine the origin of AM-manufactured components. However, this process is time-consuming. Additionally, manufacturers are often unaware of any issues until a problem occurs later in production, making it extremely difficult to determine exactly what part was altered and how.

AI Fingerprinting Study Overview

The study1 “Additive manufacturing source identification from photographs using deep learning“, published in the Nature partner journal Advanced Manufacturing, introduces an AI model that could help to solve many of these problems in the coming years. The system is capable of certifying the quality and authenticity of AP parts by using analyzed images of its layer textures.

Manufacturing Fingerprint

Every 3D printer has unique aspects that give it a fingerprint that can be detected by sensors and AI systems. Key details like the tolerances of part dimensions, process settings, and materials used correlated with individual machines.

Source – Advanced Manufacturing

How the AI Fingerprinting Process Works

The fingerprint system works on the assumption that you have the cooperation of your manufacturer, although it is not required. The first step is to collect samples of the ideal product for comparison purposes. You will need to provide specific details, including the make and model of the machine, the fabrication process, and the materials used during the production. From there, the AI system handles the rest.

Deep Learning Architecture and Model Design

The AI model can determine a 3D printer’s fingerprint from a high-resolution image of the part. It then takes the image’s details like surface texture using image downscaling, random sampling, and a voting scheme. The image is then downscaled to allow more images per model.

The engineers looked at several different AI structures before determining that EfficientNetV2 was the best option. The testing revealed that the AI model achieves high accuracy. Additionally, it ranked the fastest in terms of training time. The engineers attributed this performance to the ability to input fewer parameters and the model’s layer design.

Training the Model With 9,000+ Part Images

To train the AI, the team built a dataset that included photographs of 9,192 parts. The parts originated from 6 different manufacturers and were made on 21 machines using one of four different fabrication processes. Each part was printed and then scanned on a high-resolution Epson Perfection V39.

The scans were at 4800-dpi resolution, and each part was scanned multiple times to include a scanned serial number. The resulting 5.3 μm pixel images were then scanned in batches of 21 photos each, and their path location was sent to a randomizer. This approach helped to improve data collection input times.

Testing the Fingerprinting Method

To test their theory, the engineers created a diverse set of parts from 21 unique machines across four different manufacturing processes. The AI model randomly sampled a 448 × 448 pixel region of interest (ROI) from each part image as part of the testing phase.

Fingerprinting Accuracy Results

The AI proved its capability, scoring a 98% accuracy across 1050 parts. The model identified all key metrics of the parts, including the manufacturing process, material, and location in the machine at which the part was printed. It showed that it only needed to have as few as 10 parts to secure a printer’s fingerprint.

Why This Matters for Industry

There are a lot of benefits that this approach will bring to the market. For one, it will help to prevent loss of quality and help manufacturers determine the origins of failure. When dealing with advanced and critical systems like airliners, this approach could make the difference between life and death.

Early Detection of Faulty Parts

This AI model will also help find problems with 3D printed components before their installation. This approach will save manufacturers costs and reduce any safety risks that would occur due to the shortcomings of the incorrect part. Additionally, this approach offers scalability when compared to using human experts.

Scalability and Model Adaptability

The AI model can learn and adjust as time goes by. This detail means the system can determine identifiable features to predict other manufacturing attributes. These traits include the process, material, and machine that were used to print a component.

Applications in Industry, Supply Chain, and Forensics

There are several real-world applications of this technology. From supplier management to quality control, and even law enforcement. The ability to determine the origin of 3D printed parts is a game-changer that could help to save lives. Here are its key applications and timeline.

Industrial

The industrial sector will find an immediate use for this technology. It could prove crucial in root cause problem-solving. In the future, manufacturers could utilize image-based source identification to monitor the quality and authenticity of AM parts, helping to ensure data quality control remains effective in the 3D printer age.

Supply chain

The same benefits would make the system ideal for supply chain management. There are thousands of contract manufacturers in a major supply chain. The AI system will help companies monitor and manage the individual products that come from different locations and at varying times. The scalability of the system will allow future manufacturers to pre-verify that the parts are correct prior to installation or failure.

Investigation

Another area where this technology could help is in determining the origin of illicit goods. Everything from counterfeit parts to 3D printed guns could now become a lot easier to monitor thanks to this technology. In the past, issues like ghost guns have left politicians stumped. In the future, this technology will help law enforcement to bring more people to justice while helping to stem the flow of 3D-printed firearms globally.

Fingerprint of 3D-Printed Parts Timeline

This AI fingerprinting technology could be put to work in the next 1-3 years. There is a strong demand for the benefits this AI model brings, and it can be easily adapted and integrated into supply and manufacturing chains. These factors help to save lives and companies money.

Fingerprint of 3D-Printed Parts Researchers

The study was authored by researchers from the Grainger College of Engineering. Specifically, it lists Bill King, Miles Bimrose, Davis McGregor, Charlie Wood, and Sameh Tawfick as contributors to the work. Now the team will seek to expand their model to include more 3D printers and manufacturers.

Investing in the 3D-Printing Sector

Many companies in the AM sector could benefit from this study. Investors have seen 3d printing firms go from prototyping to creating entire neighborhoods. As such, it’s no surprise to learn that the use of 3D printing technology is on the rise. Here’s one company that continues to demonstrate a pioneering effort.

Carpenter Technology Corporation (CRS +1.07%) entered the market in 1889 in Reading, Pennsylvania. The company was founded by James Henry Carpenter and several investors to create specialty components.

Impressively, Carpenter Technology Corp has maintained a pioneering spirit and even helped to create some of the first armor-piercing projectiles for the Spanish-American War. Since then, it’s built a reputation for durability and was even used in the Wright brothers’ plane engine when they took flight for the first time in 1903.

Carpenter Technology Corporation (CRS +1.07%)

In 1917, the company made another major discovery when it introduced high-strength steel to the market. This anti-corrosive alternative was crucial to innovation in the aviation sector. Today, the company offers a wide array of products, including specialty steel, alloys, and powders for use in 3d printing applications.

Carpenter Tech’s powder options are a crucial component of complex cutting, shaping, and drilling processes, and its alloys are used across multiple industries, including transportation, defense, aerospace, energy, industrial, medical, and consumer electronics. All of these factors make CRS a strong addition to your portfolio.

Latest Carpenter Technology Corp. Stock News and Developments

More accountability → The Future of Quality Control With AI

When you look at the news and see reports about airplane components failing or other life-threatening occurrences, it’s easy to see why determining the source of faulty parts is a vital task for public safety. This new approach helps to reduce costs and opens the door for large-scale applications.

In the future, quality control will include every component of a product, prior to its installation and failure. As such, these engineers deserve a salute for their efforts that could help save lives and money.

Learn about AI breakthroughs here.

Studies Referenced:

1. Bimrose, M. V., McGregor, D. J., Wood, C., Tawfick, S., & King, W. P. (2025). Additive manufacturing source identification from photographs using deep learning. npj Advanced Manufacturing, 2(20). https://doi.org/10.1038/s44334-025-00031-2