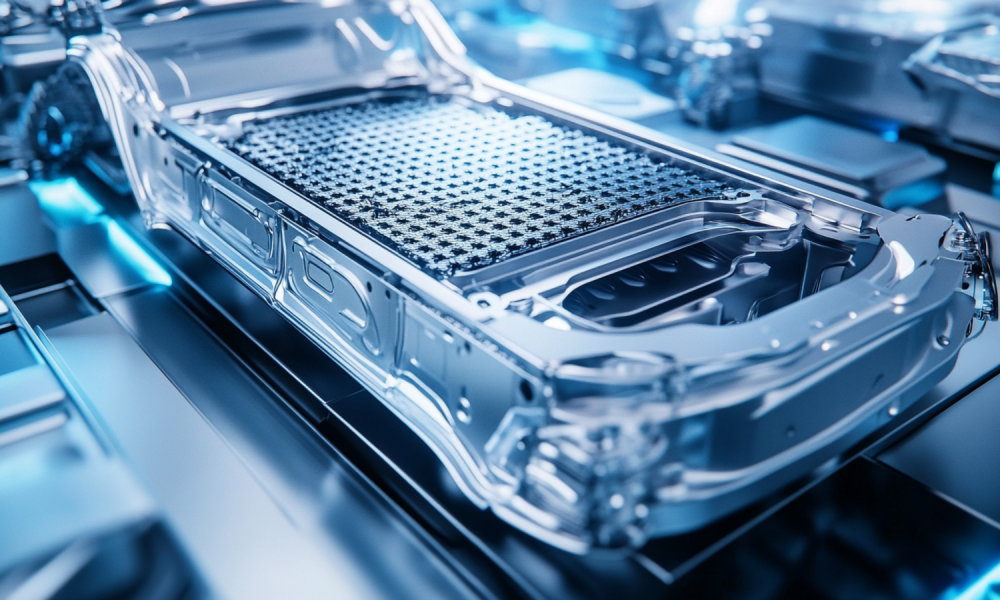

As the world moves toward electrification to increase energy efficiency and reduce greenhouse gas (GHG) emissions, the demand for batteries is growing significantly.

Notably, there is a demand for batteries that can charge ultra-fast and have high energy density in various sectors, including electric vehicles and large-scale energy storage systems (ESS), which is driving extensive research on advanced battery technologies.

What this requires is advanced anode materials with enhanced performance, which is exactly what the new study has accomplished with its breakthrough.

A joint research team, supported by the Ministry of Trade, Industry and Energy and the Ministry of Science and ICT of Korea, has developed a promising futuristic anode material1 that exhibits capabilities to tackle the crucial battery needs.

A team of researchers from Pohang University of Science and Technology (POSTECH) and the Korea Institute of Energy Research (KIER) collaborated to develop a high-energy-density anode using hard carbon and tin nanoparticles.

They introduced hard carbon-encased tin (Sn) nanodots (HCSN) as a versatile composite anode for Li-ion batteries (LIBs) and Sodium-ion batteries (SIBs) to address the current challenges with conventional batteries.

Carbon-Based Anode Innovations in LIBs & SIBs

Carbon-based materials are widely used and accepted as promising solutions for anodes in LIBs in order to enhance their electrochemical performance, which is basically the battery’s ability to store and release energy efficiently and safely.

From soft carbon, hard carbon, and graphite to various carbon nanostructures, researchers have undertaken innovations in different types of carbon materials to improve conventional batteries.

Currently, lithium-ion batteries (LIBs) are the most adopted battery chemistry. LIBs are rechargeable batteries that store energy by moving lithium ions between the cathode and anode during charging and discharging and are known for their high energy density and long cycle life. These batteries are widely used in portable electronics, electric vehicles, and energy storage systems.

However, the performance of LIBs has reached its limit, which is constrained by the anode electrodes. Not to mention, the lightest solid element, Lithium (Li), is scarce, facing rising costs, and its mining has a negative environmental impact.

This, along with the need for carbon-neutral energy storage solutions, has led to the exploration of supplementary technology, resulting in the emergence of sodium-ion batteries (SIBs).

Sodium (Na) is a very soft silvery-white metal, which is the sixth most abundant element on Earth. This most common alkali metal actually comprises 2.8% of Earth’s crust. This translates to cost-effectiveness.

To advance rechargeable battery technologies, the development of anode materials plays a major role. To develop anode materials for both lithium-ion and sodium-ion batteries, hard carbon (HC) has emerged as a promising candidate thanks to its ability to operate in extreme environments.

Hard carbon is a low-density material that cannot be easily converted to graphite, even at high temperatures. It boasts low cost, high natural abundance, and good performance characteristics.

Moreover, hard carbon is a disordered material with extremely high microporosity and pathways, facilitating fast diffusion of lithium and sodium ions. This enables it to have mechanical robustness and high energy storage, making it suitable for high-rate and long-life applications.

Yet another commonly used anode material is graphite, a form of carbon that is soft, flexible, inexpensive, and exhibits good electrical conductivity. While it offers robust structural stability, it has a low theoretical capacity and slow charge and discharge rates.

In order to overcome these limitations, the researchers came up with a new electrode design that combines hard carbon (HC) with tin (Sn), which was detailed in the journal ACS Nano.

Click here to learn how anode-free sodium solid-state batteries could reduce reliance on the ‘Lithium Triangle.’

One Anode for High-Power, Energy, & Stability

Tin or stannum is a chemical element that belongs to the carbon family. This silvery-colored metal is very soft and can be bent or cut by hand with little effort. It showcases high potential as an anode material thanks to its high volumetric capacities, low cost, high safety, and minimal environmental impact.

Incorporating tin, however, presented a challenge. To enhance overall stability, we need really fine particles of tin. The smaller they are, the more effective the reduction of troublesome volume expansion during cycling, which in turn boosts stability.

But the problem here is the low melting point of tin, about 230 degrees Celsius, which makes it difficult to synthesize small particles.

The team addressed this particular issue through the sol-gel process, followed by a controlled thermal reduction. This successfully incorporated uniformly distributed sub-10 nm tin nanoparticles within the hard carbon matrix.

The composite structure that emerged demonstrated functional synergy beyond just physical mixing.

Here, the nanoparticles of Sn acted as active materials and also served as catalysts for the crystallization of the surrounding hard carbon. The reversible Sn-O (tin-oxygen) bond formation, during electrochemical cycling, meanwhile, contributed to the gradual enhancement of battery capacity through conversion reactions.

The newly developed electrode, HCSN700, exhibited excellent performance in lithium-ion cells. The study noted that it maintained stable operation over 1,500 cycles under 20-minute fast-charging conditions. The electrode also achieved a 1.5 times higher volumetric energy density in comparison to traditional graphite anodes.

This represents the successful integration of high power, high energy, and long durability in a single electrode.

“This research represents a new milestone in the development of next-generation high-performance batteries and holds promise for applications in electric vehicles, hybrid systems, and grid-scale ESS.”

– Professor Soojin Park of POSTECH

Additionally, the electrode demonstrated outstanding performance in sodium-ion batteries.

Usually, sodium ions exhibit poor reactivity with conventional anode materials, such as graphite or silicon. But the tin-hard carbon nano-composite structure in this study maintained excellent long-term operation and fast kinetics even in sodium environments, emphasizing HCSN700’s versatility across multiple battery platforms.

“The realization of an anode with simultaneously high power, stability, and energy density, along with its compatibility with sodium-ion systems, marks a turning point in the rechargeable battery market.”

– Dr. Gyujin Song of KIER

Overall, the work highlights the HCSN700’s potential for high-power and volumetric energy density applications in next-generation energy storage systems, the study noted.

Cutting-Edge Battery Research Shaping the Future

Given the role batteries play in the future of EVs, energy storage, and the broader electrification trend, competition and innovation are driving the pursuit of batteries with improved performance and lower costs.

Researchers and companies are actively exploring new anode, cathode, and electrolyte technologies to develop the next generation of batteries. So, here are some more interesting and exciting studies that were released just this year:

A Fluid Battery That Can Take Any Shape

As we recently shared, researchers at Linköping University have developed a battery that can take any shape by using electrodes in a fluid form. This allows the soft and malleable battery to be integrated into future technologies, such as next-gen wearables, in a completely new way.

Interestingly, having a toothpaste-like texture allows the material to be used in a 3D printer, enabling one to shape the battery as desired. The new approach here involves converting the electrodes from a solid to a liquid form using conductive plastics and lignin. As a result, the battery can be stretched to double its length and still be recharged and discharged over 500 times, maintaining its performance.

Using Corn to Improve Battery Performance

Washington State University researchers have developed a way to use corn protein to enhance the performance of lithium-sulfur batteries. These batteries are lighter for the same amount of energy than LIBs, but face technological hurdles that reduce their lifespan. This includes the sulfur portion leaking and migrating to the lithium side, which causes the battery to stop working, and the formation of dendrites on the lithium side, leading to an electrical short circuit.

So, the researchers created a protective barrier (separator) from corn protein along with commonly used plastic, which prevented both issues and allowed the battery to hold its charge over 500 cycles. Additionally, corn protein is natural, abundant, and sustainable.

But with protein being “a very complicated structure,” the researchers are further studying just how the process works and how it can be optimized.

A Battery That Runs on Atomic Waste

In an interesting study from earlier this year, researchers at Ohio State University developed a battery that can convert nuclear energy into electricity through light emission. This is a significant development because while nuclear power plants produce no greenhouse gas (GHG) emissions, they create radioactive waste, disposing of which can be challenging.

However, the latest study uses a combination of solar cells and scintillator crystals, which emit light when they absorb radiation, to demonstrate that ambient gamma radiation can be harnessed to generate enough electric output to power microelectronics.

The battery was then tested, using cesium-137, which produced only 288 nanowatts, and cobalt-60, which generated 1.5 microwatts of power.

“We’re harvesting something considered as waste and by nature, trying to turn it into treasure,” said lead study author Raymond Cao, a professor of mechanical and aerospace engineering at Ohio State and the director of Ohio State’s Nuclear Reactor Lab.

A Battery That Needs to be Fed

A study from the Swiss Federal Laboratories for Materials Science and Technology (EMPA) 3D-printed a biodegradable fungal battery that can supply power to sensors used in environmental research in remote regions.

The microbial fuel cell utilizes metabolism, in which microorganisms convert nutrients into energy, and then capture part of this energy as electricity. Usually, they are powered by bacteria, but this study combined two types of fungi, for the first time, to create a functioning fuel cell.

To ensure that microorganisms can easily access nutrients, fungal cells were mixed into the 3D printing ink based on cellulose, which was then used to manufacture battery components. Researchers are now working on making their batteries more powerful and durable.

Better Understanding to Make Better Batteries

The hunt for more powerful batteries has also led researchers to study different battery chemistries and components in greater detail, to understand them better and provide valuable insights for researchers and companies to incorporate into their battery design and development.

For instance, engineers from Princeton University investigated an anode-free solid-state battery, which makes the battery even more compact and affordable. However, this composition requires good contact between the electrolyte and the current collector, and factors such as the pressure applied influence this contact. As per the study, applying a thin coating between them can help facilitate better ion transport.

A team of researchers from the Dalian Institute of Chemical Physics of CAS and the Dalian Maritime University, meanwhile, proposed adding a redox mediator and a novel imidazole iodide salt (1,3-dimethylimidazolium iodide, DMII) to enhance lithium-air batteries’ (Li-O2) performance and lifespan.

Yet another guidance comes from Weiyu Li, an assistant professor of mechanical engineering at the University of Wisconsin-Madison, who used a computational model to understand what causes lithium-ion batteries to fail: lithium plating. The model provides a way to investigate its onset over a broader range of conditions, which then helps determine the optimal way to adjust the current densities during charging to avoid it.

Innovative Company

Microvast Holdings (MVST -7.73%)

Microvast is a Texas-based advanced battery technology company that designs and manufactures battery components and systems for electric commercial vehicles, such as buses, trains, and trucks, as well as utility-scale energy storage systems (ESS). The company’s proprietary technologies range from anodes, cathodes, separators, and electrolytes to cooling systems and software controls.

Its lithium-ion battery solutions offer ultra-fast charging capabilities that can achieve a full recharge within 10 minutes, a longer lifespan to reduce the cost of ownership and support sustainability, and third-party testing to ensure quality. Additionally, they utilize superior battery components, advanced battery management, and thermal management systems for safety.

The Li-ion battery solution is available for vans, automated guided vehicles (AGVs), city and long-haul buses, light, medium, and heavy-duty trucks, mining trucks, agricultural, construction, and earth-moving equipment (ACE), as well as marine, railway, and aviation applications.

As for utility-scale ESS, Microvast’s solutions store power generated by solar or wind sources and dispatch it to the grid when needed, increasing the grid’s performance, resilience, and reliability. It includes a single 20-foot battery container featuring an industry-leading 4.3 MWh energy density, battery life greater than 10,000 cycles, and state-of-the-art fire suppression systems.

On top of that, Microvast has a proprietary battery management system, BMS 5.0, which monitors pack current, module temperatures, and cell voltages.

When it comes to Microvast’s business strategy, it focuses on production innovations, deeper participation in the battery supply chain economy, and entering into new segments with new products to diversify revenue streams.

For expanding its business, the company is working on adding production capacity to meet growing customer demand, optimizing its core business to achieve sustained profitability, and expanding through geographical and market growth.

Now, with a market cap of $757.7 million, Microvast shares are trading at $2.32, up 2.50% this year so far. With that, it has an EPS (TTM) of -0.62 and a P/E (TTM) of -3.77.

Microvast Holdings, Inc. (MVST -7.73%)

The company’s financials, meanwhile, report significant growth in revenue and gross margin for the fiscal year 2024, which was marked by operational and strategic developments. In the last year, Microvast reported a record revenue of $379.8 million, up 23.9% from the previous year. Its gross margin also improved to 31.5%, a significant increase from 18.7%.

This growth was achieved in Europe, the Middle East, and Africa (EMEA), which it expects to continue this growth into 2025.” In APAC, the company’s Huzhou Phase 3.2 expansion is underway to meet increasing customer demand as Microvast prioritizes ‘uncovering new opportunities and market segments.”

The net loss, however, jumped to $195.5 million or $0.61 per share. Its backlog, growing to $401.3 million, meanwhile, reflects strong demand for its technology. Capital expenditures were $49.9 million.

Microvast ended 2024 with $109.6 million in cash, cash equivalents, restricted cash, and short-term investments.

This year, the company is targeting revenue growth of 18% to 25%, reaching $450 million to $475 million, and a gross margin of 30%. Furthermore, the core focus for 2025 involves becoming cash flow positive and achieving high sales growth through continued innovation, new market capture, and capacity expansion.

Microvast has already announced a significant milestone in the development of its True All-Solid-State Battery (ASSB) technology this year. Its ASSB removes liquid electrolytes entirely and utilizes a bipolar stacking framework. This innovation, CEO Yang Wu said, “represents a significant leap forward in addressing real-world safety and efficiency challenges.”

Most importantly, its flexible form factor and voltage configuration enable the batteries to be custom-made to meet the specific requirements of advanced robotic systems, making the ASSB an important driver for future AI-driven applications.

Conclusion

The increasing demand for portable electronics, electric vehicles, and grid-scale energy storage systems has led to rapid advancement in battery technology, resulting in the development of and research for next-generation rechargeable batteries, which feature high energy density, cost-effectiveness, and environmental sustainability.

The latest study, which combines tin nanoparticles with hard carbon matrices, has achieved a major breakthrough by addressing the limitations of traditional anode materials and offering improved energy density, faster charging capabilities, and enhanced cycle stability. These benefits, combined with its versatility, make the novel anode highly promising for next-generation battery technology.

Click here for a list of top battery stocks.

Studies Referenced:

1. Choi, S., Han, D.-Y., Bok, T., Hwang, C., Kwak, M.-J., Yim, J.-H., Song, G., & Park, S. (2025). Catalytic tin nanodots in hard carbon structures for enhanced volumetric and power density batteries. ACS Nano, 19(10), 10476–10488. https://doi.org/10.1021/acsnano.5c00528