The Rarest Rare Metal

When people think about rare & precious metals, they tend to think of the most common ones, like gold or platinum. Or maybe some of the more industrially useful rare metals, like tungsten, rhodium, gallium, even rhenium. (follow the links for dedicated investment reports on each of these metals).

But there is an even rarer mineral in the platinum metal group, in fact one of the rarest elements in the Earth’s crust: iridium.

This ultra-rare metal, much more common in meteorites, is currently used in small amounts in many high-tech applications like aeronautics, medical imaging, and LED screens. It can also be used to generate green hydrogen, although the large-scale deployment of this technology has been hindered by the high price of iridium.

What Is Iridium?

Iridium is a very rare metal, in the same family as platinum, which is only formed in the most violent cosmic events like supermassive supernovae or the merger of neutron stars. So its relative rarity on Earth is also a reflection of its overall rarity in the whole Universe.

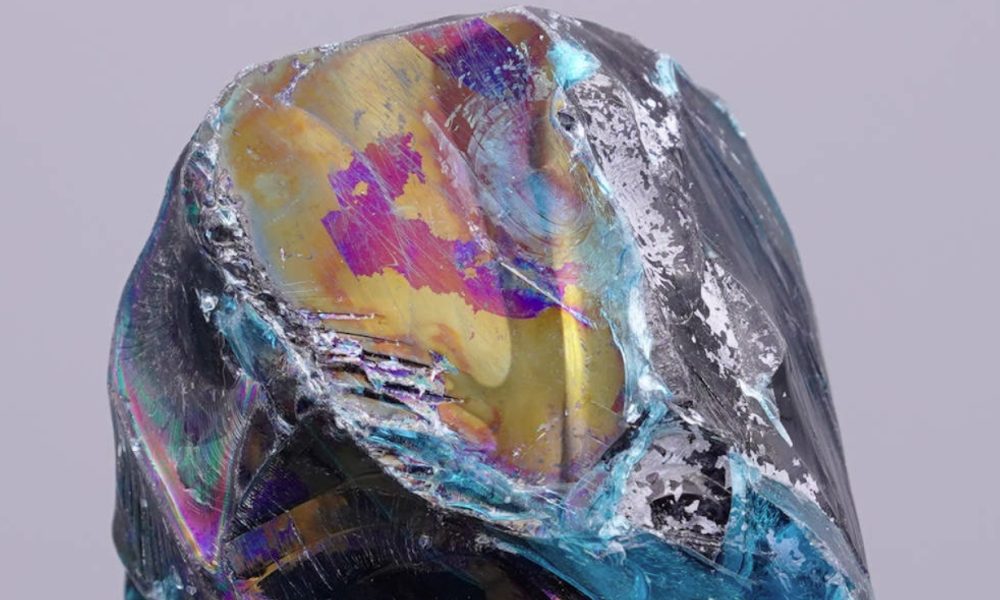

When purified, it appears as a silvery metal, although the ore and alloy can often display rainbow colors, from which it derived its name, inspired by Iris, the goddess of the rainbow in Rome.

Source: Stanford Advanced Materials

Iridium is the second-densest naturally occurring metal, after osmium. It is also extremely resistant to corrosion, even at temperatures as high as 2,000 °C (3,630 °F), and has a melting point of 2,446 °C (4,434 °F).

This extreme density contributes to its rarity in the Earth’s crust, as it sank into the planet’s core during early planetary formation. It is quite more abundant in meteorites; as a result, an unusually higher concentration of iridium in the layer of rock dated -65 million years ago is considered a strong indication that dinosaurs’ extinction was due to a large meteor impact.

As a rare mineral, iridium is generally mined together with other slightly more common metals, especially platinum and palladium.

Only 248,000 ounces, or 7 tons of iridium, have been produced globally in 2024.

Iridium’s Applications

Crucibles

Because of its extreme heat and corrosion resistance, iridium is a perfect material for crucibles (frames/molds used in metallurgy and chemistry).

This is especially the case for the production process of large oxide single-crystal leveraging, a method known as the Czochralski method, developed by a Polish scientist in 1916.

This is a crucial technology for the production of many of the most modern technologies, largely reliant on iridium-based crucibles, especially:

- Silicon semiconductors are used in computer memory, solid-state lasers, and solar panels.

- Sapphire crystal is used for smartphone glass and other screens.

- Yttrium aluminum garnet (YAG), used in high-energy/high-power lasers

- Gallium arsenide semiconductors are used to produce LED lights & lasers, medical imaging, and thin-film solar cells.

Source: AEM

Metal Alloys

When mixed with other metals, iridium gives the resulting alloy superior corrosion resistance. This is used in many specialized applications requiring high performance despite difficult environment mixing high temperature, corrosion, and wear/friction.

Aircrafts

Most of the time, the iridium is used as a coating applied to the surface of the critical part, but it can also sometimes be a constitutive part of the whole part, for example:

Parts of aircraft engines are coated with iridium, including jet engine turbines. This not only increases the durability of the parts but also minimizes surface wear and friction; iridium-coated components can operate more smoothly, enhancing the overall efficacy and longevity of aircraft engines.

Aerospace & Defense

For similar reasons, iridium coating is used in satellite thrusters, allowing them to be lighter and more durable. The Falcon 9 rocket engine also has an iridium alloy in its rocket engine exhaust.

Source: Spaceflight Now

Because iridium is very radiation resistant, it can be used to shield nuclear batteries and was notably used this way to keep the radiation of the plutonium-238 battery in NASA’s Voyager 1 and 2 space probes contained.

Iridium is also used in missile guidance systems, notably in the tip of ICBMs (Intercontinental Ballistic Missiles).

Automotive & Engines

The extreme resistance of iridium is leveraged in high-end iridium spark plugs for cars and other engines, often multiplying by 3x- 4x their durability. Iridium spark plugs are also commonly used in aviation.

Source: Niterra

Catalysis

When discussed for its uses in catalytic reaction, iridium is often mostly discussed in the context of hydrogen production, as this is a sector long-expected to boom from the demand for green hydrogen. However, iridium’s (and platinum’s) high costs have long limited the economic viability of green hydrogen produced with these metals.

It is, however, routinely used in many other important chemical processes, notably the transformation of methanol into acetic acid, the production of chlorine, and also specialty chemicals like, for example, the herbicide Metolachlor, produced by Syngenta.

Medical Imaging

A radioactive isotope of iridium, iridium-192, is used for medical applications. It is produced by exposing non-radioactive natural iridium to a neutron source.

Iridium-192 is used as a source of gamma radiation in cancer radiotherapies, especially for internal organ cancers.

Industrial Applications

Titanium-iridium alloy is used for deep-water pipes because of its corrosion resistance. It is also used in extruders (spinnerets) to form fibers like viscose.

Source: Wikipedia

In non-medical uses, iridium-192 is the key component for gamma radiography (alongside cobalt-60), a method used to analyze metals without damaging them. This is done to check welds, pipes, pressure containers, tanks, etc., especially for demanding applications like defense production or aerospace, including rocket production.

Source: GammaBuana

Other Applications

Iridium was also commonly used in the past for reinforcing the tips of pens.

Source: Sputtering Target

It is also the material chosen, due to its extreme durability from its resistance to corrosion even for extremely long period of time, as the base component together with platinum for the International Prototype Meter and kilogram mass, kept by the International Bureau of Weights and Measures near Paris, the physical reference for the measurement of a meter and a kilogram.

Source: Wikipedia

Iridium Market & Production

Due to its small volumes, the iridium market is rather small, at $1.4B per year in 2024, and is expected to grow by 4.9% CAGR until 2031.

This is also a very concentrated market, with South Africa producing 80% of the global supply, followed by Russia, and almost no other sources.

In Russia, iridium production is mostly the by-product of mining for palladium and nickel by the company Norilsk Nickel.

In South Africa, the largest producers are mostly platinum and palladium producers:

Iridium Company

Sibanye Stillwater

Sibanye Stillwater Limited (SBSW -0.8%)

By far the largest platinum-focused company, Sibanye Stillwater, is a leader in its industry.

South Africa produces 80% of the world’s platinum (and iridium), and Sibanye Stillwater is responsible for a quarter of that production (Anglo-American is a much larger, diversified miner with a focus on copper and iron).

Source: Mining Technology

It is a producer of all members of the platinum metal groups, such as platinum, palladium, rhodium, iridium, and ruthenium.

Since the acquisition of Lonmin, which at the time was producing by itself 12% of the world’s iridium supply, and combined with its own production in its platinum and palladium mines, Sibanye Stillwater is also a major actor in this niche metal.

Source: Sibanye Stillwater

The company is currently diversifying to enter the gold and battery metal markets, notably for a lithium mining project in Finland.

Sibanye Stillwater is also present in gold and uranium production. Its gold production has recently outperformed in EBITDA its platinum operations, due to record-high gold prices and platinum prices still being in a low period.

The uranium activity on the Beisa mine has been somewhat transferred to the company Neo Energy Metals (NEO.L) for $28M and a 40% stake in the company, as well as royalties on all uranium sold from the Beisa project, with Neo Energy Metals owning another uranium project (Henkries).

Source: Sibanye Stillwater

Because iridium is just a small part of the whole business, understanding the dynamic of platinum and palladium markets (and maybe gold as well) is important for potential investors in the company.

In September 2024, Sibanye Stillwater announced that it would restructure its Montana Stillwater mine, cutting this mine’s output by 45% to reduce costs. The mine, which contains more palladium than platinum, has suffered from the persistent low price of palladium.

This led to a massive $435M impairment charge, causing the company to register a loss in H1 2024.

It is also worth noticing that current prices are barely enough to cover production costs for most platinum-rich regions, making it a bottom plateau for the industry before mine closure.

Source: Sibanye Stillwater

Investors interested in iridium but concerned about the potential replacement of the metal in the catalysis market might still be interested in Sibanye Stillwater.

This is because the company has an ongoing deal with the German technology group Heraeus for the potential replacement of iridium by ruthenium, another metal produced by the mining company and which is 3.5x more abundant than iridium.

It resulted in a 90% reduction in capital expenditure for catalytic hydrogen generation, making hydrogen production more feasible.

So overall, Sibanye Stillwater is a good stock for investors looking to capitalize on the unique properties of the platinum metal group as a whole, be it iridium, ruthenium, palladium, or platinum itself. Especially as one or another of these metals are indispensable for booming high-tech applications like green hydrogen production, jet engines, missiles, space exploration, semiconductor manufacturing, radiotherapies, etc.