Pine Tree Battery

As renewables are becoming a larger part of the power grid, as well as many systems becoming electrified, like heating and transportation, more batteries are needed to balance out the intermittent power generation of solar and wind.

This puts into question the actual sustainability of a fully green power grid, as batteries tend to consume a lot of natural resources.

It is, therefore, important to develop more eco-friendly battery designs, ideally utilizing abundant or unused resources. Using less rare resources should also help decrease costs.

This can, for example, include replacing lithium with much more abundant sodium, in either sodium-ion batteries or solid-state sodium batteries.

Another option is now being developed: recycling waste from the wood industry. Researchers at the Universidad Del País Vasco in Spain are using pine biomass to create a new type of battery. They published their result in the Journal Of Power Source1, under the title “A forestry waste-derived lithium ion capacitor: Sustainable, high-power energy storage”.

Capacitor Vs Batteries

When it comes to storing electrical power, there are two main technologies: supercapacitors and batteries.

Batteries are more commonly known and store power in the form of an electrochemical charge in ions, usually metals.

Supercapacitors work differently, storing the electrons at the surface of the capacitor material. This allows them to mobilize the electric charge very quickly, making them able to deliver large amounts of power almost in an instant.

Source: Quarktwin

Because there is no chemical reaction and ions moving, supercapacitors tend to be a lot more durable than batteries.

However, supercapacitors generally have a lower total charge capacity than batteries, limiting their application for energy storage. They also present the problem of self-discharging relatively quickly when unused, an issue for any storage application like EVs and grid energy storage.

“Supercapacitors are not suitable for providing a system with energy over a long period; unlike batteries, they are used if we want a large amount of energy during a short period of time”

Eider Goikolea – Professor at Universidad Del País Vasco

Hybrid Capacitor-Batteries

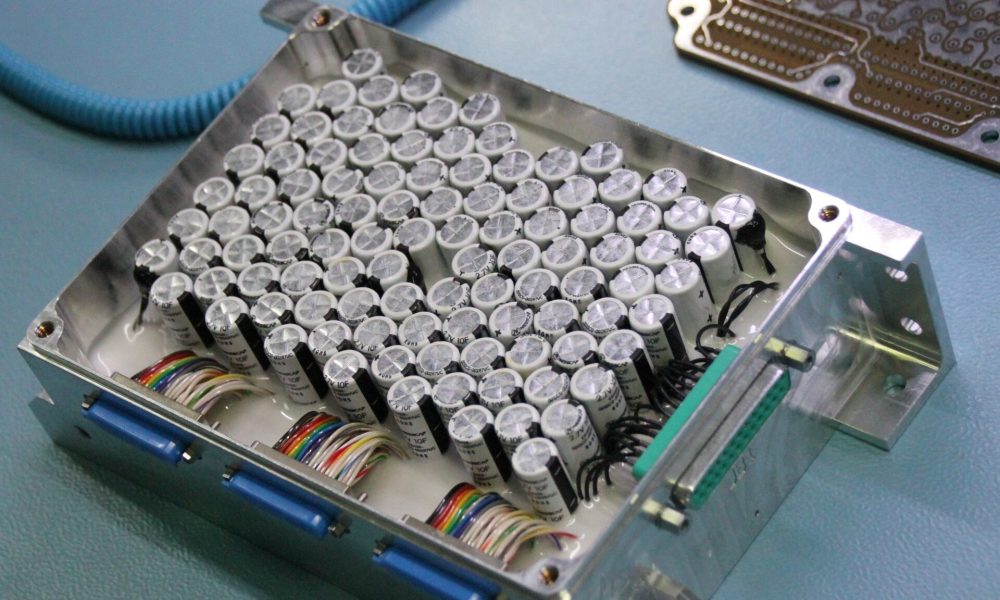

The researchers developed a hybrid system integrating both parts of capacitors and parts of lithium-ion batteries, known as a Li-ion capacitor (LIC).

It contains the electrode from a capacitor, made of carbon, and the electrode from a lithium-ion battery, made of lithium.

Source: Battery Power Tips

This is an increasingly popular concept, and some LICs have already been commercialized and proven to be an affordable option for stationary applications like windmills and electromobility applications such as trams and electric buses.

“This offers the advantages of both systems: high-power energy can be stored (as in batteries), it can operate at high-power levels and is able to withstand many charge-discharge cycles (like supercapacitors).”

Eider Goikolea – Professor at Universidad Del País Vasco

Until now, the building of LICs has required “doping”: adding other atoms to the capacitor electrode part. This boosts performance but makes the option less attractive for industrial application, as it makes the manufacturing process more complex and expensive.

Finding The Right Carbon Electrode

One material that is often used in LICs is carbon in various forms.

Graphite, because it presents excellent electronegativity, is a popular option but suffers from poor availability.

High-tech alternatives can be graphene, graphdiyne, or carbon nanotube, with potentially even better electrical characteristics, but are even more challenging to produce.

Source: Semantic Scholar

More low-tech options are soft and hard carbon, typically derived from carbon-rich materials through thermal pyrolysis. Unfortunately, the highly irregular structure of both keeps their conductivity lower than graphite.

This is where the researchers came up with an idea that both boosts the quality of the carbon used in their LIC and recycles waste streams from the wood industry.

What if they used a source of carbon that is already highly organized at the molecular level to produce their carbon-based electrode?

Activated Carbon From Pine Wood

The Basque region in Spain, where the researchers are located, is relatively rich in woodlands and has an active wood processing industry. This means that a lot of pine wood biomass is available in the form of sawdust in the surrounding sawmills.

Until now, this sawdust has mostly been discarded as waste, having few applications due to the too-small size of the particles.

Activated carbon is produced from the chemical activation of a carbon-rich material at high temperatures, using activating agents like KOH, H3PO4, or H2O. When carbonized, the product tends to retain the morphology and microstructure of the source material.

The researchers produced carbon-based electrode material from the sawdust, using a furnace and simple (and cheap) chemicals like potassium hydroxide and hydrogen chloride.

The researchers found that the process could create carbon material with better characteristics for battery material than classical hard carbon production.

Source: Journal Of Power Sources

“Carbon is a very general term, but there are many different types. Not all biomass provides the right carbon for this application, but we have shown that very satisfactory results can be obtained from the biomass of the insignis pine.”

Ruiz de Larramendi

Building Better Batteries

With that carbon material, the researchers went on to build their LIC and test it.

They found that the experimental system had an energy density of up to 105 Wh/kg, retaining 60 % capacity after 10,000 cycles.

This is an overall remarkable performance for a battery system, as, for example, a LIC system connected to the grid and performing 10,000 cycles, at one per day, would be still operating at 60% efficiency after 27 years.

The process also radically improved upon previous carbon-based electrodes, as it did not require hard-to-produce material (graphene, nanotubes, etc.), nor expensive doping of the carbon.

Overall, the whole manufacturing process was relatively low-tech and economical, making it promising for commercial applications.

“The process to produce the electrodes was energy-efficient. The synthesis temperatures did not exceed 700 °C,” and economical additives were used.

Ruiz de Larramendi – Professor at Universidad Del País Vasco

Future Applications

From a lab prototype to a commercial product, there are many steps that still need to be taken. First, optimizing the lithium-ion component of the LICs will likely allow for higher energy density and maybe even better durability.

For example, honeycomb battery structures have been demonstrated to radically improve the durability of lithium-ion batteries, and the same can likely be said for LICs.

Further characterization of what woody material is suitable or not should also be done, to know if other tree species and other regions could provide it as well.

“It constitutes a cost-effective, sustainable alternative for improving conventional lithium-ion capacitors. Materials originating from biomass offer great opportunities for developing eco-friendly, cost-effective high-power energy storage systems. It is important to further this line of research”

Ruiz de Larramendi – Professor at Universidad Del País Vasco

So most likely, it should take something like 5-9 years before the first commercial LIC using this discovery is available for sale. But it then could radically improve the sustainability of battery production from electronic devices and energy storage of renewable energy.

However, for EVs, the slightly lower energy density than pure batteries is likely going to be a problem, so other solutions like solid-state batteries are likely to win over LICs.

(see also “5 Best Solid-State Battery Stocks to Watch or Buy”)

Investing In Advanced Battery Technologies

Batteries are at the center of the trend of electrification, itself a major multi-trillion-dollar endeavor looking to remove fossil fuels from our power sources.

You can invest in battery-related companies through many brokers, and you can find here, on securities.io, our recommendations for the best brokers in the USA, Canada, Australia, the UK, as well as many other countries.

If you are not interested in picking specific battery companies, you can also look into battery ETFs like Amplify Lithium & Battery Technology ETF (BATT), Global X’s Lithium & Battery Tech ETF (LIT), or the WisdomTree Battery Solutions UCITS ETF, which will provide a more diversified exposure to capitalize on the growing battery industry.

Energy Storage Company

Tesla

Tesla, Inc. (TSLA +2.83%)

The uncontested pioneer of the EV market is Tesla, which has been at the forefront of the EV revolution.

Maybe the largest contribution of Tesla is not technology but the image of EVs. The Roadster 1.0, with a performance comparable to a Porsche (and a quite similar price tag), completely changed the expectations about EVs.

Yes, EVs could reduce carbon emissions and be “green.” But suddenly, they were also carrying a “cool” factor. This turned EVs from a “needed sacrifice to save the planet” into “the future of transportation.”

Tesla is also looking to become the first company to achieve full self-driving/robotaxi, relying on every Tesla on the road to provide an unmatched influx of data, outmatching all its combined competitors.

Source: Tesla

Together with robotic systems, as well as the Cortex supercomputer (one of the world’s largest AI training clusters), self-driving cars have solidified the image of Tesla as a science-fiction-like company going beyond electric cars.

Source: X

Tesla’s cars are powered by some of the best batteries in the world. It was supplied by Panasonic, later by CATL, and more recently by BYD, while also producing its own design.

Lastly, Tesla is active in the energy sector, with a solar panel business (Solar Roof) and fixed batteries for homes (Powerwall) and at the utility-scale level (Megapack).

Source: Tesla

This is still a nascent business line, but it might, in the long run, turn out to be as big as the vehicle manufacturing part for Tesla.

It has already deployed 10 GWh of the Megapack in 1,500+ sites, with the pace of installation picking up very quickly.

Source: Tesla

Between quickly growing car sales and even more quickly growing utility-scale battery systems, Tesla is both a leading consumer and provider of batteries in the world.

And maybe soon, equally a leader in autonomous vehicles, robotics, and AI.

Tesla is one of the most valuable companies in the world, with a stock price that has exploded upward in the last few years. And a lot of its current market capitalization reflects strong optimism about its future.

This has been slightly less true after the euphoria post-Trump election, which seems to be reverting, maybe partly due to controversies surrounding Elon Musk’s role in DOGE.

So, even with impressive technology, investors will want to check if the price they pay for Tesla is justified by future growth and if the sentiment around the company is still as strong as it used to be.

Latest on Tesla

Study Reference:

1. Jon Rodriguez-Romero, Idoia Ruiz de Larramendi, Eider Goikolea. (2025). Journal of Power Sources. Volume 629, 15 February 2025, 235961 https://www.sciencedirect.com/science/article/pii/S037877532401913X?via%3Dihub