Batteries Made To Last

As the world electrifies and switches to renewable energy, the need for more energy storage grows. This is in part driven by the switch to EVs, but also due to the intermittent nature of renewable production.

This can be partially compensated by other low-carbon sources of energy, like hydropower or nuclear, or maybe geothermal energy in the future. Still, advocates for green energy would by far prefer to see low-cost solar (and wind) be the basis of our energy systems.

This creates a demand for batteries with fundamentally different characteristics than for mobility.

EVs need very energy-dense batteries that are light enough in weight and small enough in volume to be carried in the frame of a car. Durability is a concern, but as long as the battery can function for 10-15 years, this is likely in line with the durability of the rest of the car’s components.

In contrast, energy storage batteries are much less constrained by weight or volume. However, they are definitely constrained by cost, as they are essentially an additional cost to the production of green energy and the power grid.

One way to reduce the cost of energy storage is to use less expensive material than lithium for building the battery. Many alternatives are being considered, as we previously discussed in “The Future Of Energy Storage – Utility-Scale Batteries Tech”: batteries using technologies like sodium-ion, iron-air, zinc, sea salt, polymers, sodium-sulfur, or even molten metals.

Another key element in reducing the lifetime cost of a battery system is to have it last several decades. By amortizing the investment over many years, this brings the capital cost of the battery much lower on a yearly basis. And this is something utilities companies are likely to be more comfortable with, as they are used to amortize new power plants over 30-50 year time frames.

Why Do Batteries Fail?

Death By Dendrites

Before building a battery that lasts almost forever, we need to look at why most batteries lose charge over time or stop working.

One key factor, especially lithium-ion batteries, is the growth of dendrites. This stalactite-like structure grows from the improper accumulation of metal into the battery and, over time, can break the barrier between the cathode & anode, potentially leading to a shortcut and catastrophic fire.

Source: Nobel Prize

Because of this fire hazard, dendrites are an especially serious issue for utility companies, as the fire in one battery cell could quickly spread to a whole multi-billion park of batteries nearby. So ideally, a battery technology made to last should have almost no risk of forming these dendrites.

It should also be noted that while dendrites are most discussed with lithium-ion batteries, this is a common issue for most batteries using metallic anodes and/or cathodes.

Charge Loss

Another way batteries can fail is by slowly losing their capacity to store energy. This is usually the result of some of the metal used in the electrode slowly accumulating in a form that cannot be turned back into something useful.

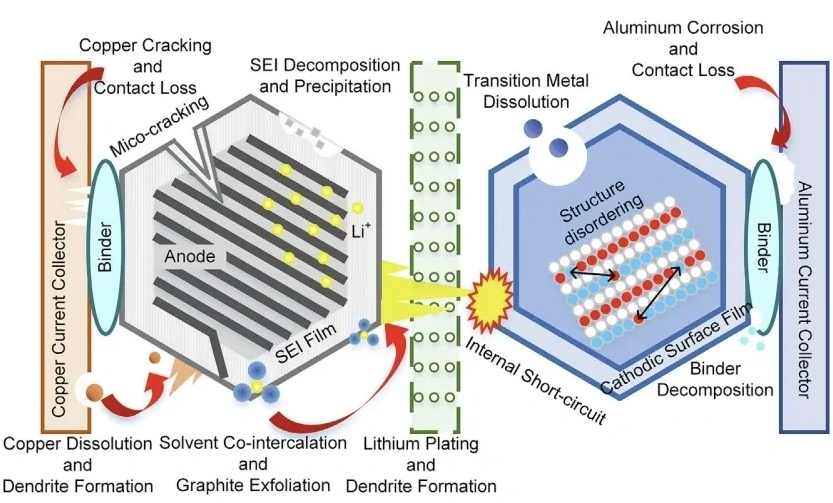

Source: EnergSoft

Other causes can be small cracks forming from mechanical and thermal stress, loss of structural integrity, accumulation of unwanted deposits, etc.

Source: EnergSoft

So the more a battery technology is susceptible to this slow degradation, the more the total charge declines, progressively rendering the battery useless. In addition, degraded batteries tend to hold charge less well and waste more of the stored energy, making them even more unprofitable.

So the ideal battery technology would be not susceptible to slow degradation of its constituent material, or could be regularly regenerated to a prime state without requiring to recycle the whole system.

If you want to learn the details of how batteries degrade, you can also consult this 22 22-minute-long video:

Cycle Lifespan

Battery durability can be a complex thing to measure. For example, most EV battery systems are usually measured on a per-mile basis, or how much distance the EVs can be driven before needing a new battery pack.

Another way to measure it is by the number of charge-discharge cycles that can be done before the battery loses a significant portion of its total charge. For energy storage, a regular cycle of charge-discharge, up to 1-3/day, is to be expected.

Lastly, how long a charge can be held is also an important question, as most batteries will lose a little bit of their charge every day. Meanwhile, the wind can stop blowing for weeks at a time, and winter days are the ones with the least sun and the highest power consumption, especially in cold climates. So in theory, a battery able to carry power without much loss for weeks or even months would be the ideal option.

Temperature Tolerance

Most battery technology can be more than a little intolerant of cold, especially freezing temperatures. As energy storage at scale will likely be done in outdoor space near a power station, this can be a serious issue in cold climates during winter. If a significant portion of the energy stored ends up being used to keep the batteries warm, this can severely impact the economics of operating these batteries.

Ultra Durable Battery Technologies

Honeycomb Batteries

Even if, ultimately, alternative chemistries will be the winners for powering a fully renewable-centered power grid, battery manufacturers are also looking at ways to make their current technology more durable.

One such example is CATL’s (300750.SZ) honeycomb batteries. The battery giant CATL, producing more than half of the world batteries, is betting big on this technology. It seems based partially on an idea proposed already back in a 2020 scientific paper titled “Stretchable lithium-ion battery based on new micro-honeycomb structure”.

Source: Phys.org

From a 2021 scientific paper, we can learn some of the key advantages of honeycomb shapes, notably low density and high out-of-plane compression and shear properties (resistance of materials to forces acting in parallel but opposite directions).

This change in the battery physical configuration keeps the material in the right place, avoiding cracks and contraction during charging.

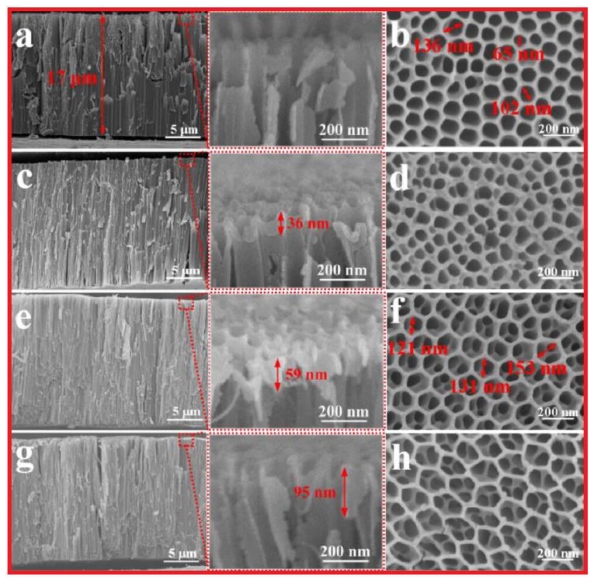

While it is not clear how CATL did it, some of these methods are known; for example, successive thermal and chemical treatments with carbon and acid can create a nano-honeycomb structure.

Source: Chemistry Europe

Source: Chemistry Europe

Overall, the honeycomb battery structure seems to avoid cracks and dendrites formation, creating an ultra durable battery while still relying on the well understood principle of lithium-ion and LFP (lithium-ferrum-phosphate) battery technologies.

It is likely at the core of CATL’s new product, the TENER containerized LFP battery system, which has demonstrated zero degradation in capacity after a full 5 years of operation.

TENER is now starting to be commercialized by CATL to utility companies.

Source: Sustainability Environment

Solid State Batteries

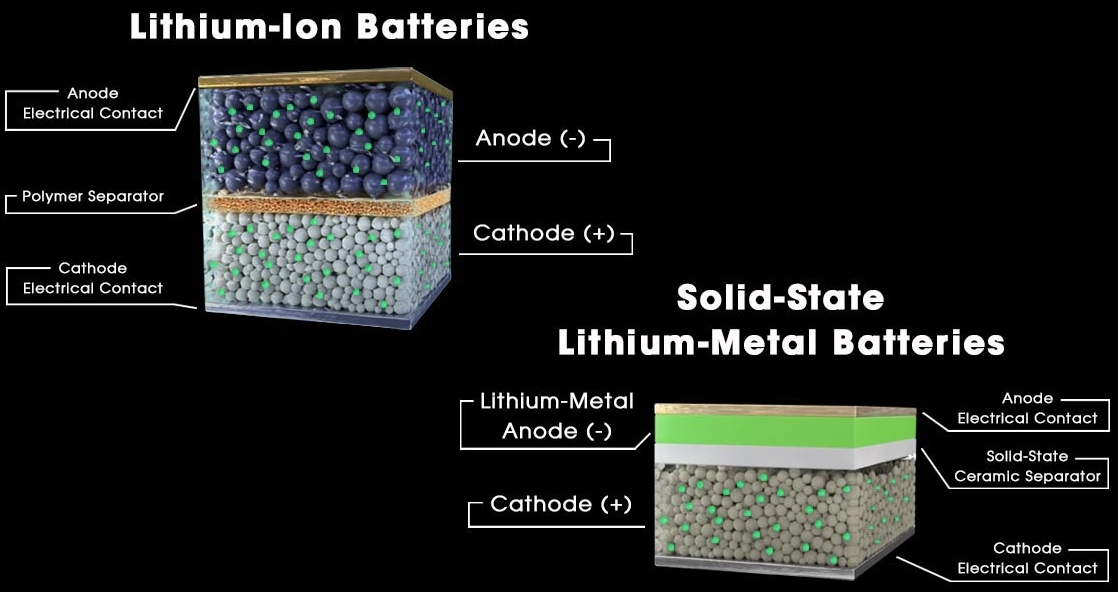

Besides modification to the chemistry, the very way batteries are built can be changed to make for more dense and more durable batteries.

This is the idea behind solid-state batteries, which replace the liquid electrolyte in most battery designs with a solid metal layer. This should be in theory building the most energy batteries, although maybe not the cheapest.

Until recently, this has been a difficult to implement at scale idea, as it requires a perfect contact between the metal layers. Mechanical movement when charging-discharging also often leads to cracks forming.

Source: Flash Battery

However, recent development by many companies like QuantumScape (QS +1.32%), Toyota (TM +0.94%), Samsung SDI (006400.KS) or Hyundai (HYMTF) of battery factories and mass production for 2028-2030 indicate the technology is now becoming mature.

In theory, well-developed solid-state batteries could progressively replace all the lithium-ion, LFP, and even sodium-ion batteries in EVs.

Their final price is yet to be seen when produced at scale to determine if they will be cheap enough for grid energy storage applications. Maybe special concepts like anode-free sodium solid-state batteries could manage this task, as it would avoid using expensive lithium metal.

(You can learn more about investment opportunities in this technology in “5 Best Solid-State Battery Stocks to Watch or Buy”).

Zinc Batteries

Because zinc is a very cheap and abundant metal, it has been used in non-rechargeable batteries for a long time. Reusable batteries can also be built with zinc, notably zinc-based aqueous batteries (ZABs).

It is, however, a design that has been plagued by dendrite formation, parasitic hydrogen evolution reaction (HER), and surface corrosion passivation, severely reducing its usefulness.

This is changing thanks to new research done at the Technical University of Munich1. They used a porous organic polymer called TpBD-2F. This material forms a stable, ultra-thin, and highly ordered film on the zinc anode, allowing zinc ions to flow efficiently through nanochannels while keeping water away from the anode.

Source: Advanced Energy Materials

The assembled full cells (Zn-ion capacitors) deliver an ultra-long cycling life of over 100,000 cycles, an astonishing durability, thanks to almost complete suppression of dendrite formation, as well as no HER and corrosion.

In addition to zinc batteries, the researchers think this concept could be expanded to other metal anodes: lithium, sodium, potassium, aluminum, etc.

TAQ-Polymer And Sodium-Ion Batteries

Polymer (carbon) and sodium instead of lithium can be a great way to reduce the price of raw materials going into a battery. This is what researchers at the MIT combined in their TAQ-sodium-ion battery.

In the initial tests, it managed 2,000 charge-discharge cycles without visible degradation, while performing with higher energy density than lithium batteries and ultra-fast 6-minute charge.

This demonstrates that, ultimately, the battery chemistry most likely to win the race for ultra-durable battery might not be just more of the same but a radical rethinking of what materials can be used in a battery, with both cheap and abundant elements like carbon and sodium good candidates.

Molten Metal Batteries

Most battery concepts are based on the transfer of electrons between one oxidation state of solid metal atoms to another oxidation state. In these, anodes and cathodes need to be perfectly separated to avoid shortcuts.

The more metal and the less liquid parts like electrolytes, the better, like in solid-state batteries, or so goes the direction of most of the battery industry.

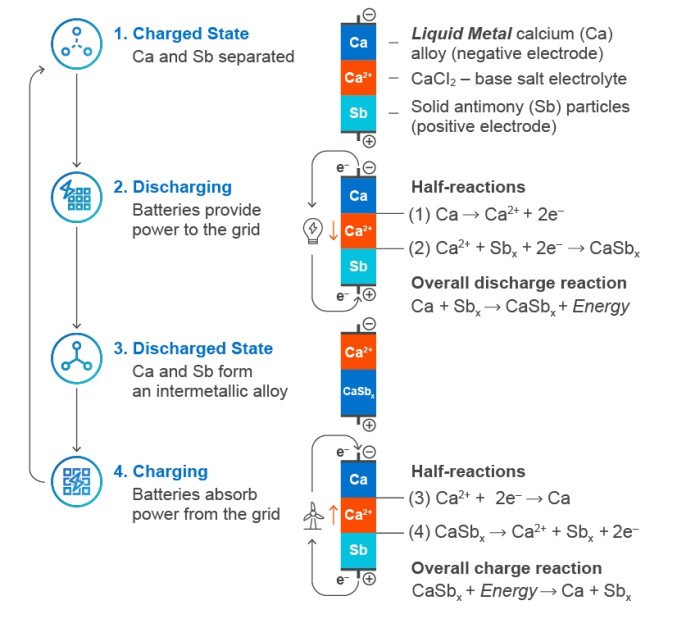

Radically expanding what can be considered a battery, molten metal batteries are doing the opposite: all three main components, the anode, cathode, and electrolyte, are liquid.

They separate spontaneously from each other thanks to different liquid densities. The fact that there are no solid components should, in theory, increase the battery’s lifespan dramatically, as well as allow it to charge and discharge very quickly and to be fully recyclable.

Source: Ambri

The Bill Gates-backed company Ambri, using a calcium and antimony battery, has been a champion of this technology. It was planning to produce 200,000 battery cells per year in its new factory by 2024.

This however did not come to pass, as the company ran out of money before it could scale-up production. It has since emerged from chapter 11 bankruptcy in summer 2024, and will still be led by co-founder Dr. David Bradwell as its CEO.

We look forward to offering our unique, safe, and low-cost commercial product to our customers at scale, to meet the strong customer demand for our battery systems, and for a cleaner energy future.

As we embark on this fresh start with a stronger balance sheet and new capital, we are focused on positioning Ambri to play a leading role in the long-duration energy storage market for the benefit of our stakeholders.”

David Bradwell

So Ambri is not dead yet, and it is not the only company working on molten batteries. Japanese NGK insulator (NGKIF) is also working on a sodium-sulfur molten salt battery, and the company Horien is working on a sodium-nickel-chloride battery.

Both company products are already commercialized and rated for a lifespan of 20+ years.

Heat / Thermal Batteries

Stretching even further the definition of battery from electricity storage to simply any energy storage, heat batteries are storing green power in the form of heat instead of electrochemical energy.

This can bring several important advantages over “normal” batteries:

- Heat retention over several months is perfectly doable with enough isolation, while chemical batteries will always leak more power on a per-day basis.

- Most of the material holding heat can be cycled hundreds of thousands of times without significant degradation.

- Materials used are cheap and abundant, like, for example, sand or pure carbon.

The combination of cheap materials, almost zero degradation over decades, and multi-month energy retention make heat batteries a good candidate.

It is mostly private companies exploring this idea, notably the Finnish company Polar Night Energy, which stores excess energy from the summer into the winter, using only low-grade sand and a bit of metal for the frame and piping.

Source: Polar Night Energy

A similar heat battery is envisioned by Rondo Energy, with ceramic bricks that can be heated to as much as 1500C, using the heat for industrial processes like cement or steel production.

Source: Rondo Energy

Overall, this can be a great option for decarbonizing sectors still consuming a lot of fossil fuels, like heavy industry and winter heating of apartments. Especially as the design can help store energy from the sunny summer to the cloudy winter.

The stored heat could even be converted back into power, thanks to thermophotovoltaics cells, with researchers at the University of Michigan having developed cells with a record 44% efficiency2.

Source: Design Boom

Conclusion

Battery systems for electric grids and homes are likely to be less reliant on the current lithium-ion technology and more on cheaper and more durable technologies, even if they are less energy dense. For now, the ones ready for mass commercialization are advanced honeycomb-structure LFP and sodium-ion batteries.

In the long term, more exotic solutions are likely to be added to the mix, like molten metal, zinc, polymer, or heat batteries. Ultimately, the durability, cost of materials, and cost of manufacturing will likely be the determining factor of which turn out to be the “final from” of ultra-durable energy storage.

That is, if solid-state batteries do not turn out cheap enough to take over the entire energy storage market, which is a distinct possibility.

Ultra-Durable Battery Company

QuantumScape

QuantumScape Corporation (QS +1.32%)

Since its foundation in 2010, Californian Quantum Scape has been a prominent startup in the solid-state battery space, remarkable by its move into the field early, and its independence from larger battery manufacturers also pursuing solid-state technology, like CATL (300750.SZ), Samsung, or LG Energy Solution (373220.KS).

Source: QuantumScape

One unique feature of QuantumScape batteries, which at the time was considered revolutionary, is that is use an anode-free design. It allows for ~15-minute fast charge (10-80% at 45 ºC) and the separator is nonflammable and noncombustible.

Source: QuantumScape

This also puts QuantumScape batteries in a league of their own when it comes to energy density and charging speed, massively outperforming leaders like Tesla (both its own design and CATL-made ones).

Source: QuantumScape

However, these remarkable performances have been regularly hindered by a struggle to ramp up production. It also forced the company to burn through its cash pile, leading to previous investors dilution and share prices decline.

This seems to be changing since the 2024 agreement with PowerCo, the Volkswagen Group battery division, for a licensing deal for the design and mass production of QuantumScape batteries by PowerCo.

Under the non-exclusive licensing deal, PowerCo can manufacture up to 40 gigawatt-hours per year of electric vehicle batteries, with the option to expand to 80 GWh a year.

The sudden scaling-up of QuantumScape production seems to be linked to Cobra, the company’s next-generation solid-state battery separator equipment, a breakthrough in ceramics manufacturing.

Overall, Cobra should be integrated into production in 2025, and the first finished EV using QuantumScape batteries should be produced in 2026.

Source: QuantumScape

This could be a turning point for the company, moving 16 years after founding from a promising startup with interesting IP to generating growing revenues from a partnership with one of the largest automakers in the world.

In the meantime, investors should still expect some volatility in the stock price, but with a light at the end of the product development tunnel.

Latest on QuantumScape

Study Reference:

1. Da Lei, et al, (2024) Ion-Transport Kinetics and Interface Stability Augmentation of Zinc Anodes Based on Fluorinated Covalent Organic Framework Thin Films. Advanced Energy Materials. 13 October 2024

2. Bosun Roy-Layinde, et al. (2024) High-efficiency air-bridge thermophotovoltaic cells. Joule. Volume 8, Issue 7, p2135-2145. July 17, 2024.