Supersonic Rebirth

Since the beginning of air travel, the industry has always looked at ways to move more people quicker and/or cheaper. When supersonic flight was invented shortly after World War II, it was expected to progressively take over the industry, at least for long-distance flights, where the extra speed converted into a much superior user experience.

It, however, did not turn out this way. While supersonic airplanes are very important in the military, civilian flights are still, to this day, mostly subsonic, taking more than half a day for intercontinental flights.

This was due to a combination of factors, from excessive costs to the difficulty of dealing with sonic booms above populated areas. As a result, the last civilian supersonic flight was in 2003.

And it might change, as a new company, the aptly named Boom Supersonic, just achieved its first supersonic flight in a test flight. And the orders for the supersonic plane are already piling up before even being commercialized.

Supersonic Flying

The term supersonic means that an object moves quicker than the speed of sound. This results in a phenomenon where the plane flies quicker than the noise it is generating. As a result, the noise (compressed air) accumulates until it creates a shock, the so-called supersonic boom.

Source: Every CRS Report

Because the air pressure is much stronger at such speeds, supersonic flight has to deal with a set of problems not seen at sub-sonic speeds:

- Excessive heat, from the friction with the air. This leads to requiring stronger materials like titanium or stainless steel instead of the usual aluminum alloy.

- For example, the Lockheed SR-71 Blackbird jet flying at Mach 3.1 could see some parts of the aircraft reaching above 315 °C.

- More air resistance also increases the energy needed and increases fuel consumption.

- The need for sufficient lift at low speeds, but low drag at high speeds, often makes engineers prefer a variable geometry for the wings or other parts of the plane, adding engineering complexity.

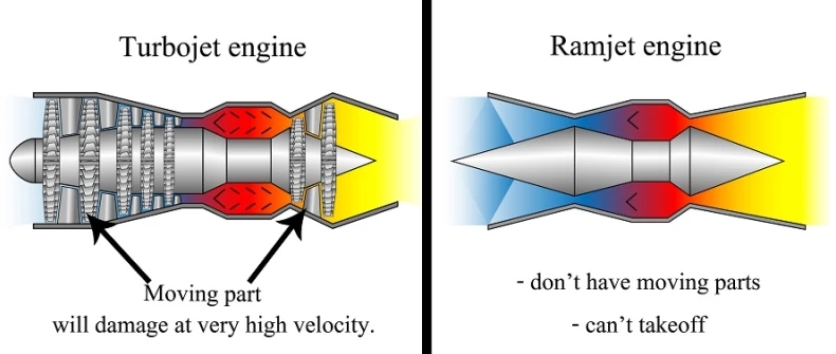

- Special types of engines like turbofans are required to reach supersonic speeds without a rocket engine.

Civilian Supersonic Flights

Progress in turbofan engines and supersonic flight led to the development of two supersonic jetliners for passenger transportation: the Soviet Tupolev Tu-144 in 1968 and the Anglo-French Concorde in 1969.

Source: Airspace Review

Reliability issues, unsolved technical issues, and the Soviet economy’s lack of demand (it would only fly one route once a week) would doom the commercial prospect of the Tu-144 early on. The Concord would have a more successful experience.

Despite a lot of political jockeying around the plane (it was initially banned from flying to New York), the Concord would join British Airways and Air France and focus successfully on trans-Atlantic flights, with a large pool of business flight clients wanting a quicker and higher-end flying experience.

The Concord also had to fight a series of concerns about supersonic flight. For example, it was believed for a few years, erroneously, that too many supersonic airliners could damage the ozone layer. It was also forbidden to use supersonic speed above inhabited areas, making the trans-Atlantic flight the only viable option to use supersonic speed for most of the travel.

Due to its lower carrying capacity, linked to its very elongated aerodynamic profile, Concord could only carry 1/3 of the passengers of an equivalent sub-sonic airliner, leading to a 3x higher fuel consumption per passenger.

As a result, Concord’s flight tickets were always somewhat expensive, limiting its total market. It did, however, ultimately turn out to be profitable, at least for British Airways.

Still, a dramatic crash in July 2000 shortly after takeoff, killing all the 109 people onboard, would ground the plane.

Source: Aviation A2Z

Its last flight would be in 2003, in part because of the crash and in part because it never managed to turn into more than a niche product, disappointing its designers, who had hoped it could become the future of air travel.

Boom Supersonic

Since the last flight of the Concord, the dream of mainstream supersonic flight has lived only in the minds of ambitious engineers.

In 2016, the announcement by Boom Supersonic that it was developing a 40-passenger supersonic jet drew attention to the company. The company was founded in 2014 and has raised a total of $150 million in total since.

Boom has been developing a technology demonstrator to test its in-house designed and built supersonic engine, as well as developing its Overture airliner and manufacturing capacity, based in the US.

Source: Boom Supersonic

The Claims of Boom Supersonic

Boom claims that thanks to progress in engineering and understanding of aerodynamics, it can “tamper” the sonic boom its airliner will produce. Even then, the supersonic speeds are expected to only happen above the open ocean.

The future airliner by Boom is also expected to be 30% more efficient than the Concord, and able to fly from Los Angeles to Sydney in 6 hours.

The first plane to go in service for commercial flight is expected in 2029, at a top speed of Mach 1.7 (1.7x the speed of sound).

Can It Work?

In the big picture, what might make Boom succeed where Tupolev and Concord failed in technological progress?

The previous supersonic airliners used aluminum instead of more advanced material, due to their design going back to the 1960s. Engine technology, as well as manufacturing techniques have also progressed a lot in the past 60 years.

And another aspect is that the company seems to have taken a page from SpaceX’s focus on vertical integration and designing everything from scratch, starting from first principles, as explained by founder Blake Scholl.

Source: Boom Supersonic

Boom’s 2025 Milestone

In January 2025, Boom testing platform XB-1 was the first civil supersonic jet made in America to break the sound barrier (Mach 1.122), doing it three times in a row above the Mojave Desert.

The aircraft is powered by three General Electric J-85-15 turbojets and was piloted by Tristan “Geppetto” Brandenburg, a graduate of the United States Naval Test Pilot School and TOPGUN Adversary, with 2500 total flight hours in 30 different aircraft and with over 200 carrier arrested landings.

The step after the XB-1 demonstrator is to scale it up to the Overture supersonic airliner.

Overture

Overture should fly at Mach 1.7 at a cruising altitude of 60,000 feet, being overall 20% faster than normal planes over land and twice faster over water. It will be able to carry 64-80 passengers, with a range of 4888 miles (7867 kilometers).

Overture will be a four-engine design, helping reduce the size and weight of each engine. This will also result in lower trust requirements for each engine, reducing the overall noise level of the aircraft.

Source: Boom Supersonic

Overture will employ the world’s first automated noise reduction system so that Overture’s takeoffs will blend in with existing long-haul fleets.

Its gull-wing shape is also going to contribute to noise reduction while being more efficient at sub-sonic speeds than the traditional delta-wing shape favored by military supersonic planes.

Like XB-1, the body of Overture is going to be built entirely of carbon-fiber composite, which expands and contracts much less than metal under supersonic conditions, solving many of the issues experienced by the previous generation of supersonic airliners. It is also lighter, allowing for greater fuel efficiency.

The company estimates that it could perform over 600+ profitable routes in the world.

Boom has already secured 130 Overture orders and pre-orders with global airlines, including American Airlines, United, and Japan Airlines.

Production

The Overture super factory, opened in June 2024 after just 17 months of construction, will aim to produce 33 aircraft annually. A planned second assembly line will double aircraft production to 66 each year.

Boom’s manufacturing program should grow North Carolina’s economy by at least $32.3 billion over 20 years, adding more than 2,400 jobs.

The factory should be LEED certified (Leadership in Energy and Environmental Design), being 40% more energy efficient than similar factories. This will be achieved thanks to urban heat mitigation materials, high-efficiency LED lighting, and water conservation.

Overall, Overture production and operation is aiming for net zero carbon, with the plan to be able to operate on 100% sustainable aviation fuel (SAF) and a strong focus on repurposing used tooling, and recycling components on the shop floor.

Additive manufacturing (3D printing) is also going to be a key part of the manufacturing process, including in the production of the engines.

Symphony

While the XB-1 test used GE engines, Overture will use the company’s own Symphony engine.

The 72″ fan will deliver 35,000 pounds of thrust, and is expected to operate, compared to other engines, at 10% lower operating costs, spending 25% more time in wing, and will be built using 3D printing.

Each engine is fed by a highly-efficient axi-symmetric inlet. These inlets provide exceptional pressure consistency that allows the engines to operate with subsonic airflow at supersonic speed.

Source: Boom Supersonic

Industrial Partners

Some aspects of the engine are being developed by FTT engineers, who worked on designing the F-22 and F-35 engines. FTT is a part of the aerospace defense company Kratos (KTOS +2.44%).

“They’re able to get a design that is going to be lower cost, it’s going to have better maintenance performance, it’s going to have massively better fuel efficiency, and they’re going to be able to get it done on the timeline that enables Boom to hit their milestones that they’ve already set.”

Liz Stein – Former aerodynamics engineer at FTT and current deep tech investor

Standard Aero (SARO +0%) will be Boom’s partner for the maintenance and servicing of the engines.

“We are excited to team with Boom as its strategic engine MRO partner and the opportunity to contribute to the company’s bright future, ensuring its aircraft will receive the industry’s finest engine MRO services.”

Russell Ford – Chairman & CEO of Standard Aero.

Colibrium Additive, a subsidiary of GE Aerospace company (GE -1.51%), will be providing the 3D printing and design consulting to Boom for the production of the engine.

ATI (ATI +7.83%) will provide the advanced high-temperature materials for Symphony’s high-pressure compressor integrated blade and disk stages, and turbine disk.

Other Technological Innovations

An unsolved issue the previous generation of commercial supersonic airliners had to deal with is the very long nose required for good supersonic aerodynamics. This led to very poor visibility during landing and takeoff.

The Concord had “solved” this with a variable-shaped nose, that proved very complex to maintain and which also added weight.

Instead, Boom adopted an augmented reality vision system in a head-worn device and on the pilot’s primary flight display, reinventing the cockpit in the process, and leveraging the Honeywell Anthem (HON +1.06%) avionics suite.

Source: Military Aerospace

Overture’s cockpit will also include force-feedback sidesticks, a first in a commercial airliner, high-definition 17-inch touch screens, and ongoing over-the-air software upgrades.

Source: Military Aerospace

An Improving Market

Besides new technology, a change compared to the Concord is that the market for supersonic flight has radically changed as well.

The world is now a lot more globalized, and more profitable supersonic routes are to be considered than the London-New York run, for example above the Arctic, over the Pacific Ocean, and in Asia.

This is supported by a few data points:

- 97% of global premium travelers are interested in supersonic flights for long-haul international trips.

- They are ready to pay 55% more than subsonic business class for supersonic travel.

- 87% would be ready to change their preferred airlines to gain access to supersonic travel.

- 64% of corporate travel influencers had airlines talk to them about supersonic.

Competitors

Boom is not alone in the race to be the first supersonic airliner of the 21st century, even if it has won a head start with the XB-1 flight. Among the most serious competitors can be mentioned:

Hypersonic Flights

If supersonic flight is promising, what about hypersonic? These flights would be so quick that they could achieve travel from New York to Paris in less than 90 minutes.

This is the path pursued by Hermeus and its future Halcyon airliner going at Mach 5.

Source: Hermeus

The company is also designing a hypersonic UAV for the US Air force (Dark Horse), and both planes will be powered by the company’s Chimera engine, to be tested in the Quarter Horse test aircraft.

Hypersonic technology relies on different engines than normal subsonic or supersonic planes, usually ramjet design.

Source: Tech Brief

Another possible technology for reaching hypersonic speeds is the detonation engine, using explosions instead of combustion to generate thrust.

Recently an even more advanced detonation ramjet, or Ram-Rotor Detonation Engine (RRDE) has been tested by Chinese scientists in simulation and could enter prototyping soon.

Source: Chinese Journal of Aeronautics

Overall, while less demonstrated technology, the hypersonic flight might be the next step, able to exceed even the promises of supersonic commercial flight.

Supersonic Engine Company

GE Aerospace

General Electric Company (GE +0.27%)

Boom Supersonic is still a privately listed company, but investors can buy shares of leading sub-sonic and supersonic engine manufacturers, of which the leader is GE Aerospace.

General Electric Aerospace is the result of the break up of the GE conglomerate into 3 parts in 2024: GE Aerospace, GE HealthCare (GEHC -0.89%), and GE Vernova (energy) (GEV -3%).

This was done to refocus the company on core competence, after several decades of financialization that has ultimately proved a net negative.

The company is a central supplier to the aeronautic industry, with around 3 billion people traveling using GE Aerospace technology per year, and around 900,000 people flying in GE-powered aircrafts at any time (3 out of 4 commercial flights). This was built on a series of engines for all aircraft sizes and applications.

Source: GE Aerospace

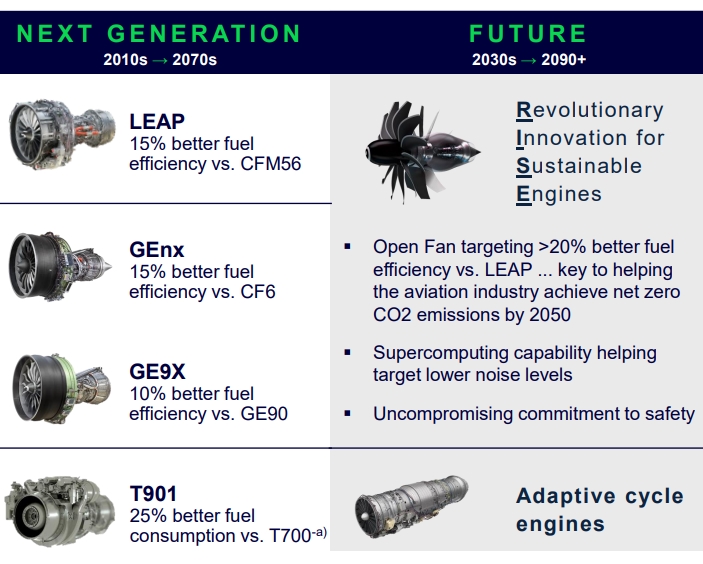

In the long term, this array of engines is expected to be replaced by a new generation with higher fuel efficiency, achieved through long-term R&D efforts. This could be in the range of 10-15% fuel efficiency improvement for civilian aircraft and up to 25% for military aircraft.

Source: GE Aerospace

Besides engines, the company is also offering silicon carbide technology for electrical power systems, and avionics (aircraft electronics and computers).

The company has long been a leader in aircraft propulsion systems. By far its activity is driven by the civilian sector ($23.9B revenues in 2023), followed by the defense segment ($9B).

70% of the company’s revenues are derived from services, especially engine maintenance and repair, making it a very stable income.

Source: GE Aerospace

The company is invested in future technology to retain its edge, notably 3D printing with GE Additive, the only OEM (Original Equipment Manufacturer) in metal additive manufacturing with a full end-to-end solution.

As we saw, it is a key partner with Boom Supersonic for the 3D printing of its own supersonic engines.

Source: GE Aerospace

GE’s Rotating Detonation Engine

GE also achieved the world-first hypersonic dual-mode ramjet (DMRJ) rig test with rotating detonation combustion (RDC) in a supersonic flow stream.

This was made possible thanks to GE’s mastery of high-temperature ceramic matrix composites (CMCs), silicon carbide power electronics, additive technologies, and advanced thermal management.

“The significant results we have had to date give us confidence that we are moving in the right direction.

The team has moved very fast, it took just 12 months from start to finish for the DMRJ with RDC demonstration. The team is on track with its goal to demonstrate a full DMRJ with RDC at scale next year.”

Mark Rettig – Vice President & General Manager, Edison Works Business & Technology Development, GE Aerospace

Hypersonic engines like this one might be first used in advanced military applications, from warplanes to missiles. But it will also likely make its way into civilian hypersonic planes one day, and GE’s presence in both markets should help capitalize on this emergent technology.

Overall, after a long period of being a directionless conglomerate and focusing on financial engineering, it seems that GE is back on track to reestablish itself as a center of American engineering and manufacturing, at a time when re-industrialization and re-shoring are strong trends.

From manufacturing Boom’s engine to already stepping into hypersonic engine technology, it seems GE Aerospace is well positioned for the next page in aerospace, both military and commercial flight.