Miniaturizing Sensors

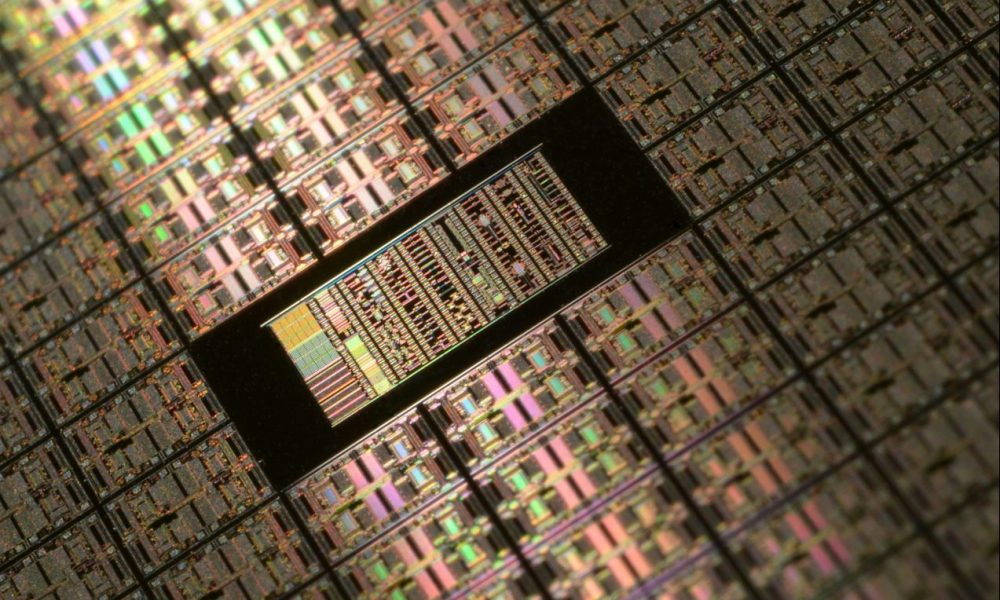

As our technology becomes increasingly precise, it also requires ever-shrinking devices. This is well known for semiconductor technology like chips, with 2 nm (nanometer) lithography now being tested by industry leaders like TSMC.

Source: TSMC

This is also true for mechanical parts, where the reaction is not primarily electric, like in semiconductors. A key element is nano-scale mechanical resonators. The very small size of these devices makes them very useful for measuring single particles.

Until now, only a limited set of non-conductive materials has been used to produce mechanical resonators. This has now changed thanks to the work of researchers at the Chalmers University of Technology (Sweden) and the University of Magdeburg (Germany).

This group of researchers has created a mechanical resonator from a new material, that has both excellent resonation properties and is also piezoelectric. These results were published in Advanced Materials, under the title “Nanomechanical Crystalline AlN Resonators with High-Quality Factors for Quantum Optoelectromechanics”.

Nanomechanical Resonators

Resonators are components like tuning forks that are able to vibrate at specific frequencies. In the case of the the tuning fork, it oscillates at its resonance frequency, producing a sound wave within our hearing range.

Today resonators have been shrunk to the micrometer and nanometer scale. These tiny resonators work at much higher frequencies than large ones, and are extremely sensitive. This makes them very good sensors for microscopic-scale measurement.

For example, such a nanoresonator can be used to measure the spins of single-proton or the gravity between small masses.

Making Resonators More Useful

Until now, most of the best nanomechanical resonators are made from tensile-strained silicon nitride. This is a material with exceptional mechanical qualities, making for a very good resonator. The problem is that silicon nitride is not magnetic, nor piezoelectric, and does not conduct electricity.

This is a problem to convert the mechanical resonance into an electric signal, or to control it directly. So overall, these silicon nitride resonators can only interact with other systems when another material is added on top of the silicon nitride.

The problem is that such an addition directly harms the performance of the resonator.

Instead, the researchers managed to create a nanomechanical resonator made of tensile-strained aluminum nitride. This material is piezoelectric, but it also displays excellent properties as a resonator, measured by a characteristic called the “mechanical quality factor” (Qm).

“The aluminum nitride resonator achieved a quality factor of more than 10 million. This suggests that tensile-strained aluminum nitride could be a powerful new material platform for quantum sensors or quantum transducers.

Witlef Wieczorek – Professor of Physics at the Department of Microtechnology and Nanoscience at Chalmers University of Technology.

Piezoelectric materials are a type of material that naturally convert mechanical motion into electrical signals and vice versa.

This electrical charge is produced by forced asymmetry: in piezoelectric materials, positive and negative charges are separated from each other, while remaining aligned in a symmetrical pattern. When mechanical stress is applied to the substance, this symmetry is lost, resulting in the production of an electric charge.

So contrary to previous versions of resonators, an aluminum nitride resonator can directly be interfaced with other nanoscale systems. And it could be used for direct readout in sensors.

How It Was Made

To develop this new type of resonator, the researchers created a highly stressed (tense) thin film of aluminum nitride 295 nm thick, by growing it on a substrate of silicon. The tension was “about 1GPa, the equivalent of balancing two elephants on a fingernail”.

Source: Advanced Material

They used a new resonator design, called trianguline, which looks like a fractal made with a central triangle-shaped pad.

Source: Advanced Material

The trianguline could be especially useful as it can maintain a single quantum coherent oscillation at room temperature. This would make it a lot easier to employ in quantum technology.

The Next Step

As a first-of-a-kind prototype, it is likely that the aluminum nitride resonator presented here can still be improved further.

The first part will be to make it with an even higher quality factor, making it more sensitive and useful. The next step will be to experiment and find how to reliably adapt the design so it can be using piezoelectricity for quantum sensing applications.

Applications

The most obvious application would be in quantum computing. Most quantum computers work by having the quantum bits (qubits) properties measured.

Qubits can exist in multiple states simultaneously thanks to two quantum properties: superposition and entanglement.

- Superposition allows qubits to represent both 0 and 1 at the same time, exponentially increasing the data that can be processed compared to classical bits.

- Entanglement links qubits in such a way that the state of one qubit can instantaneously affect another, even across great distances.

These properties enable QPUs to solve highly complex problems much faster than classical computers by exploring multiple solutions simultaneously.

However, qubits are extremely fragile, and measuring their properties is not an easy task. A room temperature resonator that is also piezoelectric could be a game changer, both in terms of performance and costs.

This could make aluminum nitride resonators a key part in the development of Quantum Processing Units able to replace our current CPU, a topic we discussed in further details in “Quantum Processing Units (QPUs): The Future of Computing” and in “The Current State of Quantum Computing”.

Other applications could stem from the resonators’ extreme precision, in niche applications low noise and long coherence time are required, like mirror suspensions, quantum cavity optomechanical devices, or nanomechanical sensors, all useful for nanodevices like LEDs, photonics computing, etc.

This is another example of how important piezoelectric materials could be in future technologies. You can learn more about this topic from some of our articles covering these materials:

Investing In Nanotechnology

Nanotechnology is becoming a growing segment beyond the making of semiconductors, with promises of wonder materials for the aerospace, biotech, energy, and chemical industries.

You can invest in nanotech companies through many brokers, and you can find here, on securities.io, our recommendations for the best brokers in the USA, Canada, Australia, the UK, as well as many other countries.

If you are not interested in picking specific nanotech companies, you can also look into nanotechnology ETFs like the ProShares Nanotechnology ETF (TINY) or the Direxion Nanotechnology ETF (TYNE) which will provide a more diversified exposure to capitalize on quantum dots & nanotech stocks.

Or you can look at our list of the “Top 10 Nanotechnology Stocks” and 5 Best Quantum Computing Companies.

Resonator Company

SiTime Corporation (SITM -4.25%)

As our computers and electronics become more complex, having exact measurements becomes even more important, in some cases a matter of life or death.

This is the focus of SiTime, a company centered around accurate time measurement using silicon technology. This is similar to how quartz crystals are used in watches (a 70-year-old technology), except for its superior performances:

- Extreme resistance to interferences from shock, vibration, changes in temperature, jitter, and noise.

- Small size and low power requirements.

- Programmable and higher performance.

Source: SiTimes

SiTime is the company responsible for creating the concept of “precision timing,” a segment growing 30-35% a year and on which the company has a 90% market share.

As a “fabless” semiconductor company, SiTime focuses on developing its IPs, leaving the actual manufacturing to industry leaders, a similar business model to Nvidia for its GPUs and AI chips.

More precise time measurement through precision timing is becoming a must, as new computing and telecom technologies are moving very fast:

- 5G connectivity is 10x the speed of 4G

- Data centers are also operating 10x quicker than a few years ago, and poised to accelerate with growing AI applications.

- Automotive and other vehicles are incorporating a lot more electronics today, and before the advent of robotaxis (all autonomy levels above 2 need precision timing).

- SiTime offering the “FailSafe” technology where the single device integrates resonators, oscillators, clocking, and advanced safety mechanisms for timing in autonomous vehicles. Shipments in volume will only start in 2025.

- The aerospace sector is growing quickly with companies like SpaceX leading the way in both more material launched, and new applications like low latency space-based Internet.

From a startup with little revenues in 2019 (mostly from oscillators) and launching its first resonators in 2020, SiTime has grown very quickly, increasing at once revenues, gross margin and operating margin.

Source: SiTimes

This followed the overall growth of the Serviceable Addressable Market (SAM) for SiTime from $1B in 2021 to $4B in 2024, as part of the overall larger $10B “timing market”.

Source: SiTimes

SiTime has invested over $500M in R&D cumulatively since inception. The micro-electromechanical systems (MEMS) industry tends to favor a structure where one company almost entirely dominates a segment, as the barriers to entry are high (R&D costs, technical expertise, patents) and clients tend to stick to the industry leaders.

This puts SiTime as the leader of “timing MEMS”, alongside other companies like Broadcom (AVGO -2.64%) for radio frequency or Bosch for inertial sensors (SiTime was a spin-off from Bosch, before being bought by the Japanese company Megachips and listed on NASDAQ in 2019).

With AI data centers, 5G deployment, satellite telecommunication, and self-driving vehicles all exponentially growing sectors, SiTime is well positioned to itself grow very quickly, and become a less-known but vital cornerstone of the ongoing connectivity & AI revolution.