A Mundane Revolution

Some Nobel Prizes in Physics are attributed to a revolution in the fundamental way we understand the universe, from black holes (2020) to subatomic particles (2013) or the expansion of the Universe (2011). Others are rewarding seemingly more “mundane” discoveries that are nevertheless entirely worth winning for the durable and radical impact they will have on human civilization.

The 2014 Nobel Prize, attributed to Isamu Akasaki, Hiroshi Amano, and Shuji Nakamura for the discovery of blue light-emitting diodes, is one of them.

LED diodes capable of emitting red, yellow, and green light have been known since the invention of LED technology. However, to emit white light, LED diodes emit blue light where required, and this proved difficult to achieve.

The Right Type Of Light

Quantum Energy

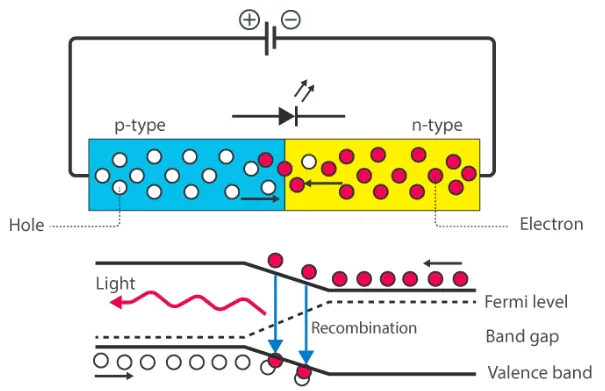

What makes blue light so difficult to produce with LED stems from the fundamental physics of LED diodes.

LEDs produce light thanks to the principles of quantum physics. In a simplified version of quantum physics, atoms are formed by a nucleus, around which orbits one or several electrons, not unlike the Earth around the Sun.

Due to quantum mechanics rules, these electrons can only “orbit” around the atoms’ nucleus in predetermined levels, each determined by a certain energy level. When an electron travels from a high to a low energy level, the surplus is emitted in the form of light.

Low-energy light tends to be on the “red side” of the light spectrum, while higher-energy light tends to be on the blue side of the spectrum.

Source: Online Learning College

LED Basics

This ability of atoms to emit light, stemming from fundamental physics, is the base principle behind LED diodes. In practice, a few more specific characteristics are needed.

To create an LED diode, you first need materials that are semiconductors, hence have the ability to either let an electric current pass or block it (hence the “semi” qualifier).

You must then combine 2 different types of semiconductors:

- One able to give away electrons is also named the “n-type.”

- One with extra room to receive said electrons, also named the “p-type”.

Semiconductor combinations used in LEDs have a “band gap”, with a significant difference in energy potential between the 2 materials.

When electrons move from one semiconductor to the other, the energy released becomes the light we want from the diode.

Source: BYJUS

Early LED systems had very small energy differences between the 2 types of semiconductors, leading to low-energy infrared light being emitted. Quickly, scientists and electronic companies figured out how to boost this energy gap by some amount, leading to visible light LEDs in red, yellow, and green colors.

A key part of these improvements was the “spiking” of the previously pure semiconductor materials with other elements, which boosted their performances.

Source: Wikipedia by VectorVoyager

This method was insufficient for several decades to create the high-energy bandgap required for LEDs to emit blue light.

The Tricky Path To Blue LED Diodes

Gallium Nitride – A Tricky Miracle Material

The band gap of the materials used for lower-energy LED lights, like gallium arsenide (1,42 eV) and gallium phosphide (2,26 eV), used for red and green LEDs, was short of the 2,6 to 3,4 eV for blue light.

An alternative was found with gallium nitride (3,37 eV). Using gallium nitride for creating blue LED light seemed a good idea, but doing it in practice was seemingly impractical.

Source: Britannica

The first hurdle was that no method existed for preparing a surface on which to grow gallium nitride crystals. In addition, no one knew how to make a p-type layer of gallium nitride either. Many had tried and failed to turn gallium nitride into a functional LED system for blue light. This is where the three winners of the 2014 Nobel Prize entered the fray.

Solving Blue Led From Multiple Angles

In 1986, Isamu Asaki and Hiroshi Amano were the first to figure out how to grow gallium nitride crystals on a layer of aluminum nitride on a sapphire substrate.

They would create a p-layer a few years later, and finally create the first prototype of bright blue light LED in 1992.

In parallel, Shuji Nakamura began developing his blue LED in 1988. He had found his own way to grow the gallium nitride crystal, first growing a thin layer of gallium nitride at a low temperature and growing subsequent layers at a higher temperature.

True Understanding Of Gallium Nitride

Asaki and Amano’s p-layer was optimized by exposing the gallium nitride to the electron beam of a scanning electron microscope.

Nakamura had the theoretical framework to explain how the electron microscope worked: it was removing hydrogen atoms, preventing the p-layer from forming. He then came up with a simpler & cheaper method to achieve the same result: controlled heating of the material.

Both parallel research groups kept going with increasingly advanced and complex designs for their blue LED, creating various alloys of gallium nitride with aluminum or indium, effectively doping the semiconductors to boost their light output and efficiency.

Source: Nobel Prize

They also invented blue lasers using their blue light LED. Because the blue light frequency is much smaller than other colors, it can contain 4x more information than infrared light, opening the way to Blu-ray disks.

Blue LED Light Achievements

More Light From Less Electricity

Blue LEDs made it possible to create white light, making it possible to replace most light bulbs and fluorescent lamps with LEDs. This is particularly notable, as LEDs are 20x more efficient than light bulbs and 4x more than incandescent lamps.

Source: Nobel Prize

Because 1/4th of electricity consumption is for producing light, this represents a radical saving on global energy consumption.

It also makes off-grid illumination systems much more viable, with small solar panels or other alternative energy sources now able to power light in remote or poor areas. This, in turn, allows for increasing productivity and better education.

Customized Colors

In addition to white LEDs, the combination of red, green, and blue LEDs allows for the creation of all possible colors of the visible spectrum. This opens the way to all sorts of specialized LEDs for niche applications.

A major application of blue LEDs and custom colors on demand has been LED screens for TVs, computers, and smartphones, as fluctuations in the red/green/blue ratio are responsible for displaying the right color pixel by pixel.

Or, for example, plants do not use green light for photosynthesis. So LED lights for indoor cultivation can use only red and blue LEDs, optimizing greatly the power consumption of greenhouse cultivation and making possible the revolution in hydroponics and urban farming. And maybe one day even growing food in space or on Mars.

Source: Agritecture

Ultraviolet LEDs

After the initial development of blue light LED, further improvements have made an even more powerful system emitting ultraviolet light possible.

These UV-C LEDs can be used to purify water at any scale, from camping gear to utilities servicing tens of millions of people in large cities. They can also be used to kill airborne pathogens and sterilize surfaces, for example in hospitals.

Blu-Ray And Blue Lasers

As mentioned before, blu-ray and other high-density data storage solutions reliant on blue laser would not have been possible without blue LEDs. The high data density is equally useful for optical communication, especially when high bandwidth is required.

Blue lasers are also “the ideal light source for high-reflective metal processing, offering substantial advantages in various industrial applications such as cutting and welding”.

Blue lasers are also now used for surgery of the larynx, thanks to their high-energy output and the absorption of the 445nm wavelength by hemoglobin, allowing a very precisely targeted coagulation of blood vessels.

Gallium Nitride Beyond LED Lights

Blue LED lights created a whole industry producing at scale and studying gallium nitride crystals. This, in turn, might create a revolution in the design of electronics, with gallium nitride being called “the next big thing in power electronics”.

Gallium nitride can work at much higher temperatures and higher voltage than silicon-based field-effect transistors (FETs). So, gallium nitride-based could be used for 5G cellular base stations, transistors, small electronic devices, and even AI, as computing applications require higher and higher energy consumption.

All these applications would not be possible without the economies of scale in production and the wealth of knowledge created by the blue LED industry in the first place.

Blue Led Companies

Nakamura-Related Companies

Nakamura developed its blue LED light when working at Nichia Corporation. After a change of leadership in 1989, the company had actually ordered Nakamura to stop working on the project, which he luckily did not. This was good news for the company as well, which quadrupled its revenues between 1993 to 2001, with 60% of total business coming from blue LED lights.

Nakamura left Nichia in 1999, and he would later on be involved in a complex series of lawsuits over the ownership of the technology, involving Nakamura, Nichia, and US-based competitor Cree. Nakamura would ultimately settle for a ¥840 million (≈US$8.1 million) payment with Nichia.

Nakamura would move on to found 2008 Soraa, a privately listed company selling blue LEDs, that was recently acquired by Ecosense in 2020.

In 2022, Nakamura co-founded Blue Laser Fusion, a commercial nuclear fusion company. It looks to use mega-joule pulse energy lasers with a fast repetition rate to achieve commercial fusion. The company plans to complete its first prototype in 2025 and demonstrate a commercial-ready fusion reactor by 2030.

Blue Laser Fusion is backed by the Mirai Creation Fund, which is itself backed by Toyota Motor and other investors.

With Soraa/Ecosense and Nichia (to not be conflated with Nichias – NICFF) privately listed companies, investors have to look at other blue LED light manufacturers to invest in that technology that became a basis of modern innovation in electronics, telecommunication, medicine, manufacturing, and even agriculture.

1. SMART Global Holdings

Cree was an American company that was among the first to mass commercialize blue LED lights and a major competitor of Nakamura-related Nichia. It was also behind the first commercial silicon carbide wafer.

Later it rebranded to ‘Wolfspeed‘, and sold its LED business to SMART Global Holdings in 2021.

Source: SGH

SGH managed four different brands:

Cree LED represents around 1/5th of total revenues, and intelligent platform solutions make up half of total revenues.

So, SGH is not a purely LED-focused company. However, Cree LED is the owner of important IPs (notably the XLamp Brand), with a reputation for technological excellence in the field and a presence in all blue LED-related markets.

2. Osram (OSAGF)

Osram is a global company that leads in sensors and innovative light solutions. The semiconductor segments, including LEDs, lasers, integrated circuits, and sensors, represent 2/3 of the company’s revenues.

It is notably #1 in many categories:

- Auto LED and laser lights.

- Traditional auto lights.

- Horticulture LED.

- CT Medical imaging.

Source: OSRAM

Overall, OSRAM is #2 in the LED market with 13% market share, behind Nichia (15%), but well ahead of the rest of the competition like #3 & #4 Seoul Semiconductors (7%) and Samsung LED (7%), and MLS (6%).

OSRAM is also the leader in light sensors, with 29.2% of the market, just ahead of STMicroelectronics (28.5%).

Most of the company’s revenues come from the Asia-Pacific region, with recent revenues almost equally split between EMEA and the Americas.

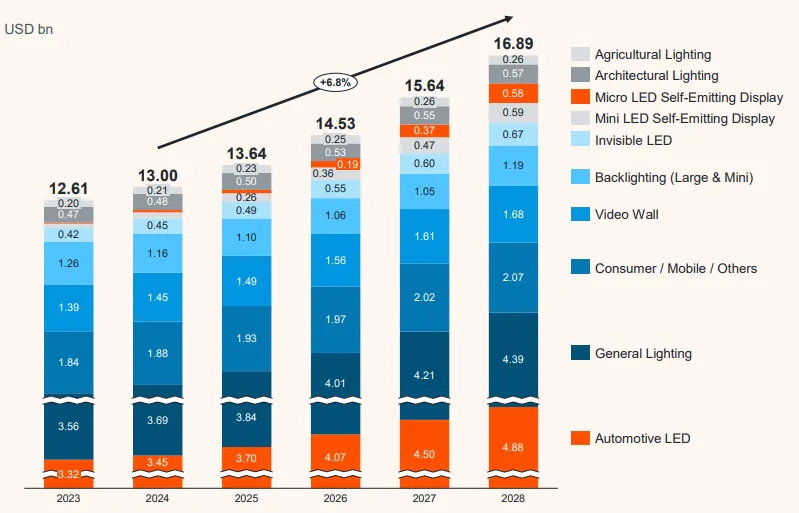

The LED market is expected to continue growing at a 6.8% CAGR until at least 2028. This is mostly due to the automotive and general lighting LED markets.

Source: OSRAM

With the lead of OSRAM in the automotive market, both classical and LED lamps, as well as horticulture, the company is almost sure to see its total addressable market continuously grow for the next few years.