Hydrogen combustion has emerged as one of the most promising fuel options, offering significant environmental value and performance. At a design level, these engines date back more than four decades.

In 1970, inventor Paul Dieges patented a modification that enabled gas-powered internal combustion engines to run on hydrogen. Since then, this technology has advanced greatly in its ability to power vehicles, cars, and buses. Its potential is so great that future commercial aircraft may also adopt hydrogen as their primary fuel.

In Hydrogen Combustion Engines, either liquid or gaseous hydrogen burns in a modified gas turbine engine to generate thrust. This process mirrors traditional internal combustion but with hydrogen replacing its fossil fuel counterpart.

With its growing use and importance, speculations are rife about which HCE has the most exciting future. In the following segments, we look at five hydrogen combustion engines that are all set to break the mold.

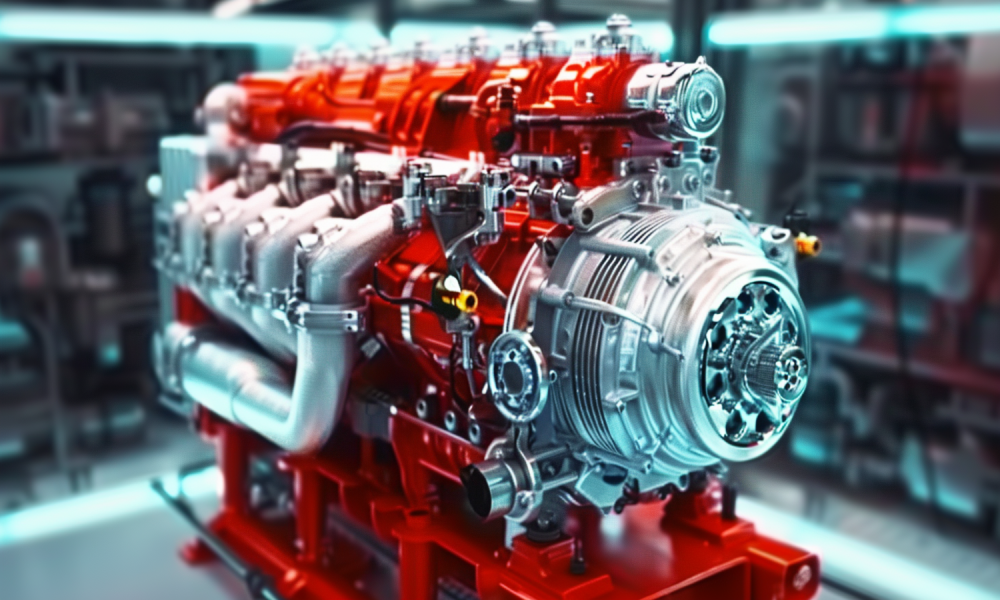

Cummins 15-Litre Hydrogen Engine

Cummins”s 15-liter engine platform, which, which we discuss,, is fuel-agnostic at its core. It is compatible with hydrogen, natural gas, and diesel. But when deployed with hydrogen, it can truly break the mold by becoming the best version of its low-to-zero carbon fuel capability range and accelerating the decarbonization of heavy-duty off-highway applications to their optimum.

While speaking about its specialty, Antonio Leitao, the Vice President of Cummins’ Global Off-highway Engine Business, had the following to say:

“Cummins’ all-new platform takes internal combustion to a new level, capable of meeting future ultra-low emission standards, such as EPA Tier 5 and EU Stage 6, together with a low-to-zero carbon fuel capability to help put construction and quarrying sites on a lower cost path to decarbonization. The 15-liter has a significant increase in power density with a more compact installation envelope providing equipment manufacturers with the capability to do more with their machines.”

If we discuss the specific case of the hydrogen engine, it comes with a direct-injection, lean-burn combustion with ratings from 400-to-530 hp (298-395 kW) and a peak torque of 2600 N·m. Drawing power from zero-carbon green hydrogen, it can use a 700-bar pressure high-capacity fuel storage system for maximum operating hours between refueling.

The version is expected to be in full production by 2027. The company will produce these engines with 15-liter and 6.7-liter displacements.

The engine has been getting validation from industry stakeholders from its very early days. In January 2022, Werner Enterprises (Nasdaq: WERN), a premier transportation and logistics provider, decided to begin validating and integrating Cummins’ 15-liter hydrogen internal combustion engines in its vehicles.

Cummins reported its fourth quarter and full year 2023 results on February 6th, 2024. Fourth quarter 2023 revenues of $8.5 billion increased 10% from the same quarter in 2022, while revenues for the full year 2023 were $34.1 billion, 21% higher than 2022.

Yamaha’s 5.0-litre V8 100% Hydrogen-Powered Engines for Toyota

Toyota Motor Corporation commissioned Yamaha Motor to develop the hydrogen engine of the future. The five companies—Kawasaki Heavy Industries, Subaru Corporation, Toyota Motor Corporation, Mazda Motor Corporation, and Yamaha Motor—decided to conduct collaborative research into exploring and expanding the range of fuel options for internal combustion engines suited for carbon neutrality.

While speaking about the development, Yamaha Motor president Yoshihiro Hidaka said:

“Hydrogen engines have the potential to be carbon-neutral while keeping our passion for the internal combustion engine alive at the same time. Teaming up with companies with different corporate cultures and areas of expertise, as well as growing the number of partners we have, is how we want to lead the way into the future.”

In the unveiling event for the engine, the 5.0-litre V8 appeared to be based on the 5.0-litre engine in the Lexus RC F luxury sport coupe, modified to injectors, cylinder heads, intake manifold, and more. The engine could deliver up to 450 hp at 6,800 rpm and a maximum of 540 Nm of torque at 3,600 rpm. The high-performance 5.0-litre 90-degree V8 DOHC 32-valve engine was converted by Yamaha to use hydrogen.

According to its annual report for 2023, Yamaha recorded a group-wide consolidated revenue of 451.4 billion Yen with a core operating profit of 45.9 billion Yen.

The Engine for BMW iX5 Hydrogen

BMW has been testing its future vehicle since 2023. From temperatures of up to 45°C to sand, dust, various inclines, and fluctuating humidity levels, the company has tested it all. The company also finds its hydrogen fuel cell technology suitable for everyday use in extreme sub-zero temperatures.

In terms of specifics, the BMW iX5 Hydrogen’s fuel-cell system can consistently deliver a high output of 125 kW/170 hp.

Toyota Motor Corporation has been commissioned to manufacture the individual cells for the BMW Group. The BMW Group Plant, Landshut, makes the casing for the stack, which comes second in the two-step manufacturing process. The first step involves stacking the cells and fitting the other components.

The fuel cells that deliver the performance of 125 kW/170 hp is an innovative combination that comes from the BMW Group’s Gen-5 range of BMW eDrive technologies and a specially developed battery. When combined, the set-up is capable of offering an output of up to 285 kW/401 hp.

BMW Group has also been responsible for developing the dedicated hydrogen components, including the high-resolution compressor with a turbine and the high-voltage coolant pump. The inner mechanism of the fuel cell prompts the hydrogen from the tanks to react with oxygen from the atmosphere to produce electricity that powers the motor. The two tanks present in the BMW iX5 Hydrogen are capable of holding a total of 6 kg of the gas and empowering the system with a vehicle range of 504 km in the WLTP cycle.

BMW groups also deem the iX5 engine the future of refueling as hydrogen refueling is faster than recharging a battery-electric car.

BMW’s association with hydrogen has been holistic. Its group plant logistics has been using the gas since 2013. It was also the company that erected Germany’s first indoor hydrogen station at the Leipzig plant. The PaintShop at Plant Leipzig is involved in piloting the use of hydrogen in vehicle production as well.

In 2023, BMW Group reported annual revenues of around 155.5 billion Euros, a 9% increase from its 2022 figure of close to 143 million Euros.

Volvo’s Hydrogen Combustion Engines with High-Pressure Direct Injection (HPDI) Technology

The Volvo trucks set to come with a hydrogen combustion engine will have high-pressure direct injection (HPDI) technology, which means that a small amount of ignition fuel, injected with high pressure, can enable compression ignition even before hydrogen is added. One of the many benefits of this technology is that it retains high levels of energy efficiency with lower fuel consumption. It ensures that engine power is not compromised in the process.

The Volvo Group has already signed an agreement with Westport Fuel Systems to establish a joint venture utilizing HPDI technology, which is expected to become operational in the second quarter of 2024.

While elaborating on Volvo’s strategy with its hydrogen engines, Jan Hjelmgren, Head of Product Management and Quality at Volvo Trucks, had the following to say,

“Trucks, where the traditional internal combustion engine remains but runs on hydrogen, will have the same performance and reliability as our diesel trucks, but with the added benefit of potentially net zero CO2 emissions well-to-wheel. They will be a valuable complement to our battery electric trucks, which have been on the market for several years.”

Customer tests with Volvo trucks that use hydrogen in combustion engines will begin in 2026, and the trucks will become commercially available towards the end of this decade.

HPDI technology is a transformative addition to how our transport systems will work in the future. It addresses the challenges of meeting the regulatory requirements of Euro 7 and the US EPA for trucking and off-road equipment manufacturers globally.

The injector with a dual concentric needle design can reduce 97% of CO2 emissions. It is why trucks running on this technology can be categorized as “Zero Emission Vehicles” under the agreed new EU CO2 emission standards. The engines will also produce very small amounts of nitrogen oxides and particles.

In 2023, Volvo Group’s currency-adjusted net sales grew by 11% to SEK 552.8 billion, and its adjusted operating income improved to SEK 77.6 billion.

Click here to learn what made hydrogen more attractive as an energy source recently.

Hydrogen Combustion Engine Developed in Collaboration by Kia and Hyundai

In a latest move that could prove pioneering, Kia and Hyundai, two Korean automobile giants, have teamed up to design a hydrogen combustion engine. The engine may become ready for passenger cars by 2025.

Reports suggest this engine can potentially solve all the problems of durability and large-scale viability that hydrogen engines have faced until now. The prototype is that of a 180-200 horsepower 2-liter hydrogen engine with torque and power curves comparable to the equivalent gasoline engines in size. The benefit is that the hydrogen engine does far better when it comes to fuel consumption. The engine can sustain high thermal efficiency throughout its operation by infusing hydrogen into the combustion chamber at a pressure of 30 bar.

To augment the production of the engine, Hyundai and Kia have also struck partnerships with a couple of vendors. For example, it has signed a memorandum of understanding with Next Hydrogen Corporation, a Canadian company that specializes in water electrolysis technology. The development of an alkaline water electrolysis system will improve the price competitiveness of clean hydrogen for Hyundai and Kia.

The company has also signed an agreement with W. L. Gore & Associates (Gore) to jointly develop advanced polymer electrolyte membrane (PEM) for hydrogen fuel cell systems. The PEM facilitates the transfer of protons between electrodes in the fuel cell. As the PEM blocks the direct combination of incoming hydrogen and oxygen, selective conduction of protons happens, and, in turn, an electrical current is generated to power a vehicle.

According to Chang Hwan Kim, Head of Battery Development and Hydrogen and Fuel Cell Development at Hyundai Motor Company and Kia Corporation:

“We are entering the next chapter of our partnership with Gore. By leveraging the 15 years of collaboration, we will acquire advanced fuel cell technology and lead the fuel cell electric vehicle market, accelerating the movement towards a sustainable future.”

For the financial year 2023, Hyundai registered an annual revenue of 162,664 billion KRW, a more than 14% increase from its 2022 revenue of 142,152 billion KRW. In 2023, Kia registered a revenue of 99,808,420 million KRW.

The Future of Hydrogen Combustion Engines Looks Promising than Ever

From passenger vehicles to trucks, all leading global auto manufacturers are investing as much resource and research as they can to make Hydrogen Combustion Engines the best possible option for a carbon-neutral, sustainable, green future.

Apart from offering us a clean environment, these engines are superior in many other ways. For instance, they take away the need for a heavy battery pack, a common feature among EVs. The hydrogen-to-electricity converter stack is compact and lighter than a lithium-ion battery with a power train with a similar range. It only takes 3 to 5 minutes for a hydrogen combustion engine to refuel, and its energy density is at least 3-times greater compared to batteries, while between one fill, they can go 2-3 times longer than that of most EVs.

Here, we have had the chance to look into almost all the major engine types in the category set to break the mold. The future could be well expected to be replete with more such cutting-edge innovations.

Click here to learn why hydrogen may still be the fuel for the future.